Preparation method of recombinant bamboo

A technology for recombining bamboo and bamboo segments, applied in chemical instruments and methods, flat products, manufacturing tools, etc., can solve the problem of poor compatibility between protective agent and adhesive, inability to form a uniform and stable mixed phase, changing glue and protective agent Use performance and other issues to achieve the effects of strong production continuity, comprehensive drug effect distribution, and cost-saving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] raw material

[0034] Bamboo tow: 3 to 4 years old bamboo, straight and free of defects. After thawing, rolling, carbonization and other processes, it is made into bamboo tows with a length of 300mm, a width of 15-20mm, and a thickness of 2-4mm, which do not break in the transverse direction and are relatively loose in the longitudinal direction.

[0035] Adhesive: water-soluble phenolic resin, viscosity 60-110mPa·s (30°C); pH=9-11; solid content 47%, diluted with water to 25% solid content, ready for use.

[0036] Antifungal agent: agent A (organic iodine compound 3-iodo-2-propargyl butyl carbamate (IPBC), derived from Sanbo Biochemical Technology (Shanghai) Company), which is light yellow transparent liquid, water soluble Excellent sex. Preparation steps:

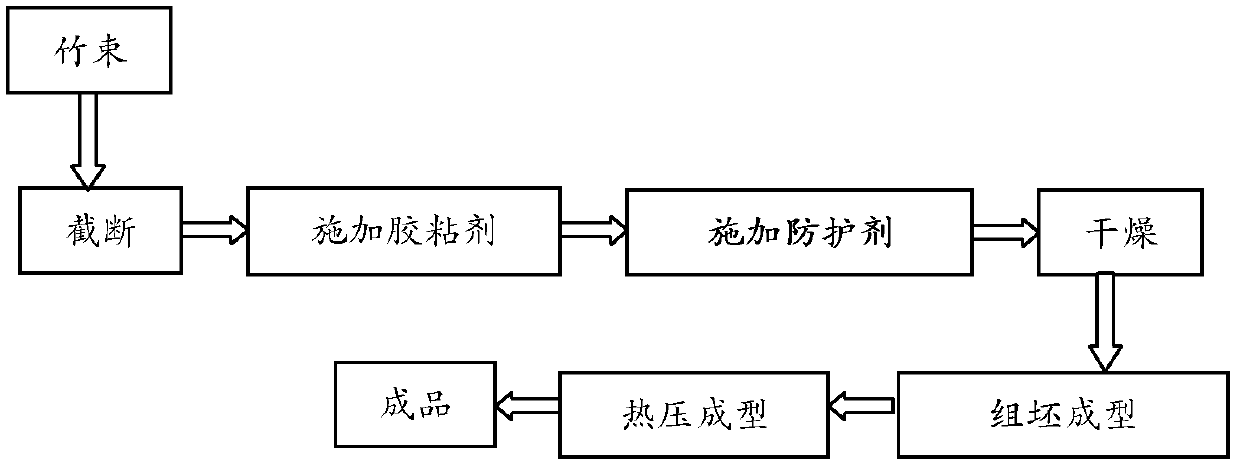

[0037] See figure 1 , the preparation method of recombinant bamboo in the present embodiment comprises the following steps:

[0038] 1) cut off: according to the format of the experimental mould, the bamboo to...

Embodiment 2-12

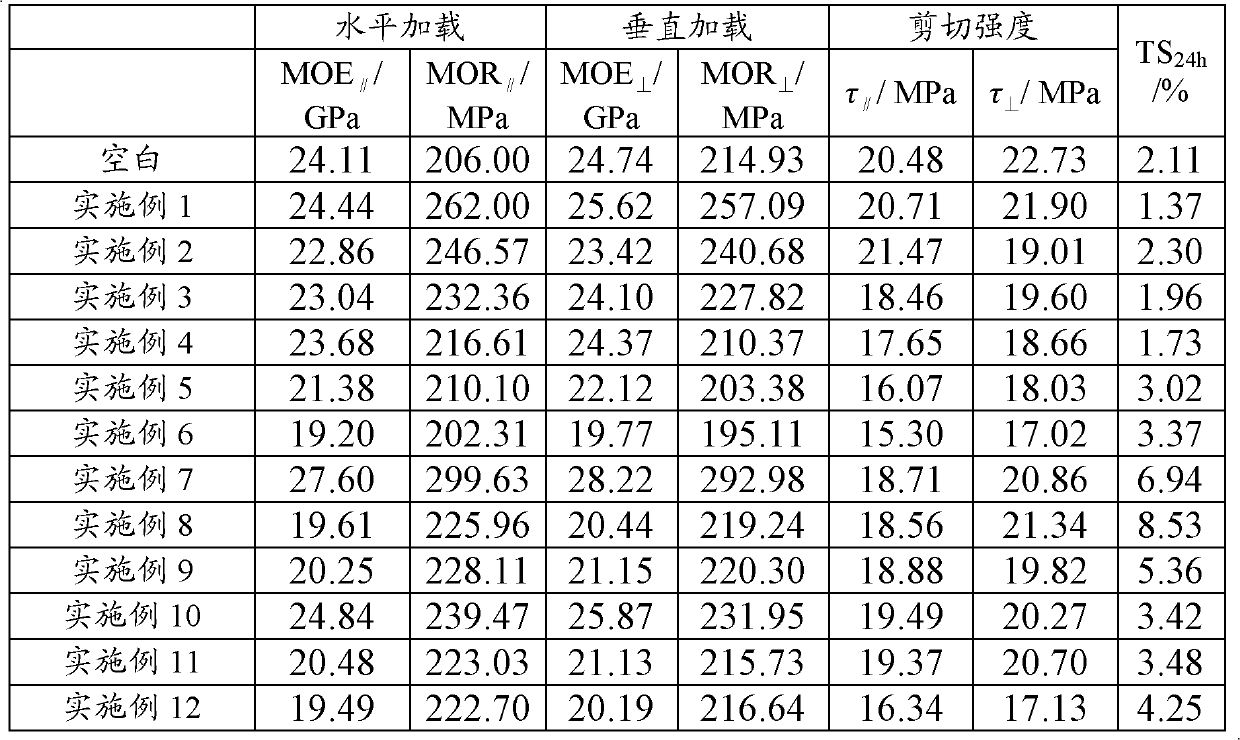

[0044] The preparation method of the recombinant bamboo of the embodiment of the present invention 2-12 is basically the same as embodiment 1, and difference is:

[0045] Embodiments 2 and 3 use different contents of drug A, and the contents are shown in Table 1 below.

[0046]Embodiment 4-6 uses different contents of medicament B (didecyldimethylammonium chloride (DDAC), derived from Sanbo Biochemical Technology (Shanghai) Co., Ltd.), which is a colorless transparent liquid and is easily soluble in water; implementation The specific content of the agent B used in Examples 4-6 is shown in Table 1 below, wherein the agent B is diluted to a concentration of about 1.5%.

[0047] Examples 7-9 use different contents of medicament C (IPBC+DDAC (1:1) compound), which is a water-soluble transparent liquid; the specific content of medicament C used in Examples 7-9 is shown in Table 1 below, where Agent C was diluted to a concentration of about 1.5%.

[0048] Embodiment 10-12 uses dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com