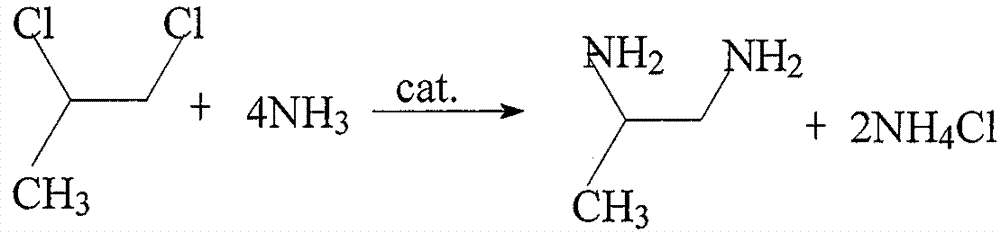

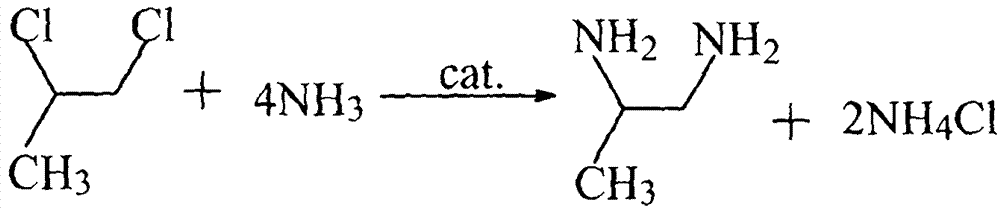

Supported catalysts for the preparation of 1,2‑propylenediamine

A supported catalyst, propylenediamine technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of amino-substituted functional groups, etc., can solve side reactions, insufficient reactions, rapid, etc. Problems, to achieve the effect of convenient operation, beneficial to industrial production, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Accurately weigh 1g SiO 2 Suspend it in 20 mL distilled water, then weigh 0.3196 g CuCl 2 2H 2 O, it was added to the suspension, and the mixture was sonicated for 30min so that the SiO 2 for uniform dispersion. Heat the mixed solution after ultrasonication at 100°C until the solution is evaporated to dryness, then transfer it to an incubator at 120°C for 2 hours, and finally transfer it to a muffle furnace for calcination at 400°C for 3 hours . The prepared catalyst CuO / SiO 2 for the next catalytic reaction. The content of CuO is 15% of the weight of the carrier. Add 5 mL of 1,2-dichloropropane, 0.5 g CuO / SiO to the reaction kettle 2 , 100mL ammonia water. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. The temperature was lowered to room temperature, unreacted ammonia gas was removed, and gas chromatography was used to detect that the yield of 1,2-propanediamine was...

Embodiment 2

[0022] Accurately weigh 1g TiO 2 Suspend it in 20 mL distilled water, then weigh 0.3196 g CuCl 2 2H 2 O, it was added to the suspension, and the mixture was sonicated for 30min so that the TiO 2 for uniform dispersion. Heat the mixed solution after ultrasonication at 100°C until the solution is evaporated to dryness, then transfer it to an incubator at 120°C for 2 hours, and finally transfer it to a muffle furnace for calcination at 400°C for 3 hours . The prepared catalyst CuO / TiO 2 for the next catalytic reaction. The content of CuO is 15% of the weight of the carrier. Add 5 mL of 1,2-dichloropropane, 0.5 g CuO / TiO to the reaction kettle 2 , 100mL ammonia water. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. The temperature was lowered to room temperature, unreacted ammonia gas was removed, and gas chromatography was used to detect that the yield of 1,2-propanediamine was...

Embodiment 3

[0024] Accurately weigh 1g Al 2 o 3 Suspend it in 20 mL distilled water, then weigh 0.3196 g CuCl 2 2H 2 O, it was added to the suspension, and the mixture was sonicated for 30 minutes to remove Al 2 o 3 for uniform dispersion. Heat the mixed solution after ultrasonication at 100°C until the solution is evaporated to dryness, then transfer it to an incubator at 120°C for 2 hours, and finally transfer it to a muffle furnace for calcination at 400°C for 3 hours . The prepared catalyst CuO / Al 2 o 3 for the next catalytic reaction. The content of CuO is 15% of the weight of the carrier. Add 5 mL of 1,2-dichloropropane, 0.5 g CuO / Al to the reaction kettle 2 o 3 , 100mL ammonia water. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. Cool down to room temperature, remove unreacted ammonia gas, and detect by gas chromatography, the yield of 1,2-propanediamine is 68.39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com