Preparation method of organosilicon aluminum powder corrosion inhibitor, organosilicon aluminum powder corrosion inhibitor and application thereof

An organosilicon and corrosion inhibitor technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of large usage, atmospheric corrosion, and overall safety of equipment affecting the service life of metals, and achieves convenient operation, simple equipment conditions, and improved resistance to corrosion. Effects of Atmospheric Corrosion Protection Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

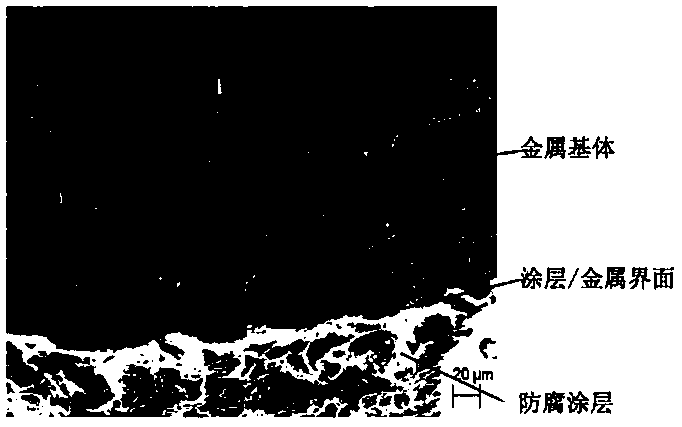

Image

Examples

Embodiment 1

[0035] A preparation method of the organosilicon aluminum powder corrosion inhibitor of the present invention comprises the following steps:

[0036] (1) Add butyl acetate cellulose to the container, then add dichloropropane, ethyl acetate and ethylene glycol in sequence, the mass ratio of butyl acetate cellulose, dichloropropane, ethyl acetate and ethylene glycol is 28:17:42:13, stirred evenly at room temperature, and filtered to obtain the cellulose acetate precursor for use.

[0037] (2) Add silicone-modified acrylic resin, hydroxyacrylic resin and the cellulose acetate precursor obtained in step (1) into the container, stir until evenly mixed, then add adhesion promoter and nano-montmorillonite, the adhesion The accelerator is specifically Carity-130 adhesion promoter, but it is not limited thereto. Other adhesion promoters can also be used. Mix evenly under 750r / m high-speed stirring, and then add aluminum powder slurry, which is made of dichloro Soak the aluminum powder i...

Embodiment 2

[0044] A preparation method of the organosilicon aluminum powder corrosion inhibitor of the present invention comprises the following steps:

[0045] (1) Add butyl acetate cellulose to the container, then add dichloropropane, ethyl acetate, ethylene glycol in sequence, the mass ratio of butyl acetate cellulose, dichloropropane, ethyl acetate and ethylene glycol is 26:19:43:12, stirred evenly at room temperature, and filtered to obtain the cellulose acetate precursor for use.

[0046] (2) Add silicone-modified acrylic resin, hydroxyacrylic resin and the cellulose acetate precursor obtained in step (1) into the container, stir until evenly mixed, then add Carity-130 adhesion promoter and nano-montmorillonite, Stir at a high speed of 720r / m until the mixture is uniform, then add the aluminum powder slurry obtained by soaking aluminum powder in dichloropropane, stir at a low speed of 200r / m, and finally add butyl acetate to adjust the viscosity of the paint (the viscosity is withi...

Embodiment 3

[0053] A preparation method of the organosilicon aluminum powder corrosion inhibitor of the present invention comprises the following steps:

[0054] (1) Add butyl acetate cellulose to the container, then add dichloropropane, ethyl acetate and ethylene glycol in sequence, the mass ratio of butyl acetate cellulose, dichloropropane, ethyl acetate and ethylene glycol is 24:17:44:15, stirred evenly at room temperature, and filtered to obtain the cellulose acetate precursor for use.

[0055] (2) Add silicone-modified acrylic resin, hydroxyacrylic resin and the cellulose acetate precursor obtained in step (1) into the container, stir until evenly mixed, then add Carity-130 adhesion promoter and nano-montmorillonite, Stir at 650r / m until evenly mixed, then add the aluminum powder slurry obtained by soaking aluminum powder in dichloropropane, stir at 140r / m, and finally add butyl acetate to adjust the viscosity of the paint (the viscosity is within 16-20 centistokes), Filter to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com