Preparation method of high-permeability paste for polyester-cotton blended fabric

A polyester-cotton blended, high-permeability technology, applied in the field of printing and dyeing, can solve the problems of unclear pattern outline, high printing cost, and high price, and achieve the effects of improving dyeing permeability, not easy to decolorize, and reducing color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

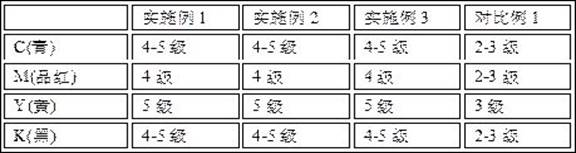

Examples

Embodiment 1

[0028] A preparation method for polyester-cotton blended fabric high-permeability paste, comprising the following steps:

[0029] A, after attapulgite is pulverized, cross 120 mesh sieves;

[0030] B. Add water to the pulverized attapulgite and carry out ball milling for 30 minutes, then add sodium bicarbonate, modified nano-silicon dioxide, octadecylamine polyoxyethylene ether and aluminum chloride, after stirring evenly, add chitosan;

[0031] C. After stirring at a high speed of 3000rpm, let stand for 20 minutes, pass through a 250-mesh sieve to obtain a precipitate and a suspension, continue ball milling the precipitate, and spray-dry the suspension to obtain a mixed powder;

[0032] D. Stir the mixed powder and guar gum at a stirring speed of 300rpm for 20min to obtain a paste.

[0033] In the described step B, add the raw material of following weight portion:

[0034] Attapulgite 40 parts

[0035] 100 parts of water

[0036] Chitosan 12.5 parts

[0037] Sodium bicar...

Embodiment 2

[0044] A preparation method for polyester-cotton blended fabric high-permeability paste, comprising the following steps:

[0045] A, after attapulgite is pulverized, cross 120 mesh sieves;

[0046] B. Add water to the pulverized attapulgite and carry out ball milling for 25 minutes, then add sodium bicarbonate, modified nano-silicon dioxide, octadecylamine polyoxyethylene ether and aluminum chloride, after stirring evenly, add chitosan;

[0047] C. After stirring at a high speed of 3500rpm, let stand for 18 minutes, pass through a 250-mesh sieve to obtain a precipitate and a suspension, continue ball milling the precipitate, and spray-dry the suspension to obtain a mixed powder;

[0048] D. Stir the mixed powder and guar gum at a stirring speed of 320 rpm for 18 minutes to obtain a paste.

[0049] In the described step B, add the raw material of following weight portion:

[0050] Attapulgite 45 parts

[0051] 100 parts of water

[0052] Chitosan 10 parts

[0053] Sodium b...

Embodiment 3

[0060] A preparation method for polyester-cotton blended fabric high-permeability paste, comprising the following steps:

[0061] A, after attapulgite is pulverized, cross 120 mesh sieves;

[0062] B. Add water to the pulverized attapulgite and carry out ball milling for 20 minutes, then add sodium bicarbonate, modified nano-silicon dioxide, octadecylamine polyoxyethylene ether and aluminum chloride, after stirring evenly, add chitosan;

[0063] C. After stirring at a high speed of 4000rpm, let it stand for 15 minutes, pass through a 250-mesh sieve to obtain a precipitate and a suspension, continue ball milling the precipitate, and spray-dry the suspension to obtain a mixed powder;

[0064]D. Stir the mixed powder and guar gum at a stirring speed of 400rpm for 15min to obtain a paste.

[0065] Preferably, in the step B, the following raw materials are added in parts by weight:

[0066] Attapulgite 35 parts

[0067] 100 parts of water

[0068] Chitosan 15 parts

[0069] 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com