Improved all-cotton fabric printing method

A printing method and fabric technology, applied in the field of printing, can solve the problems of poor washing fastness and easy fading, and achieve the effect of high color fastness to washing and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

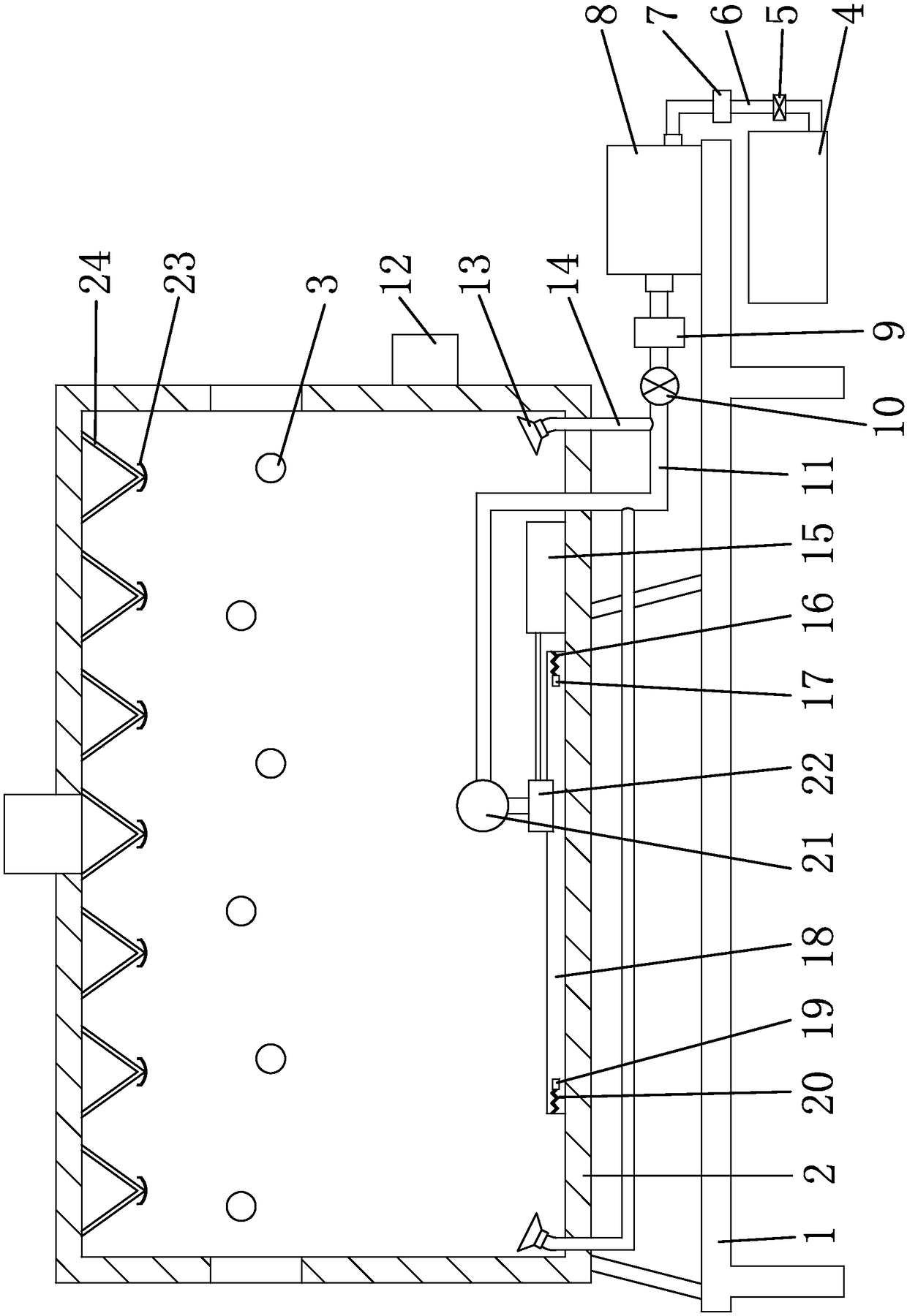

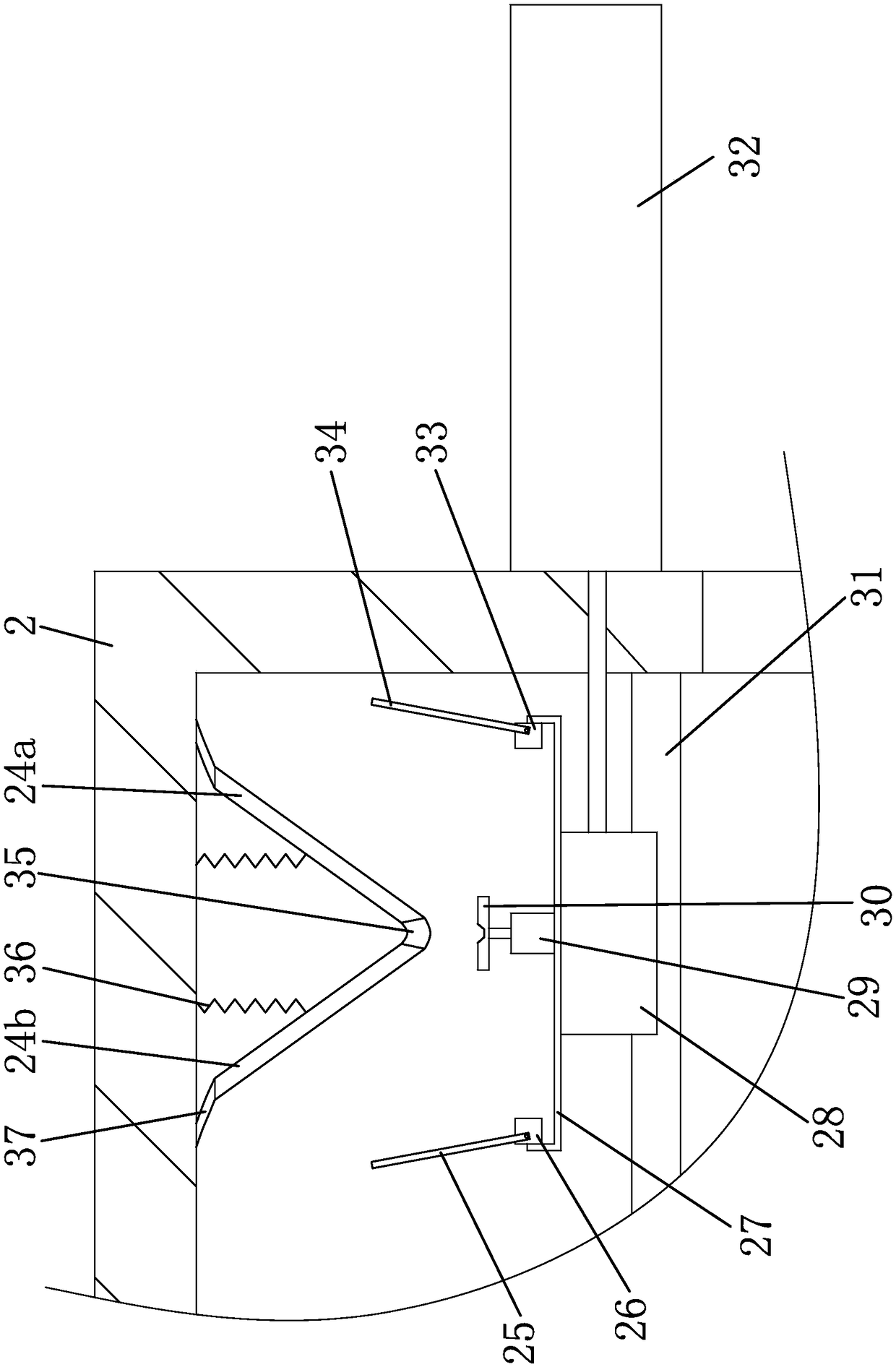

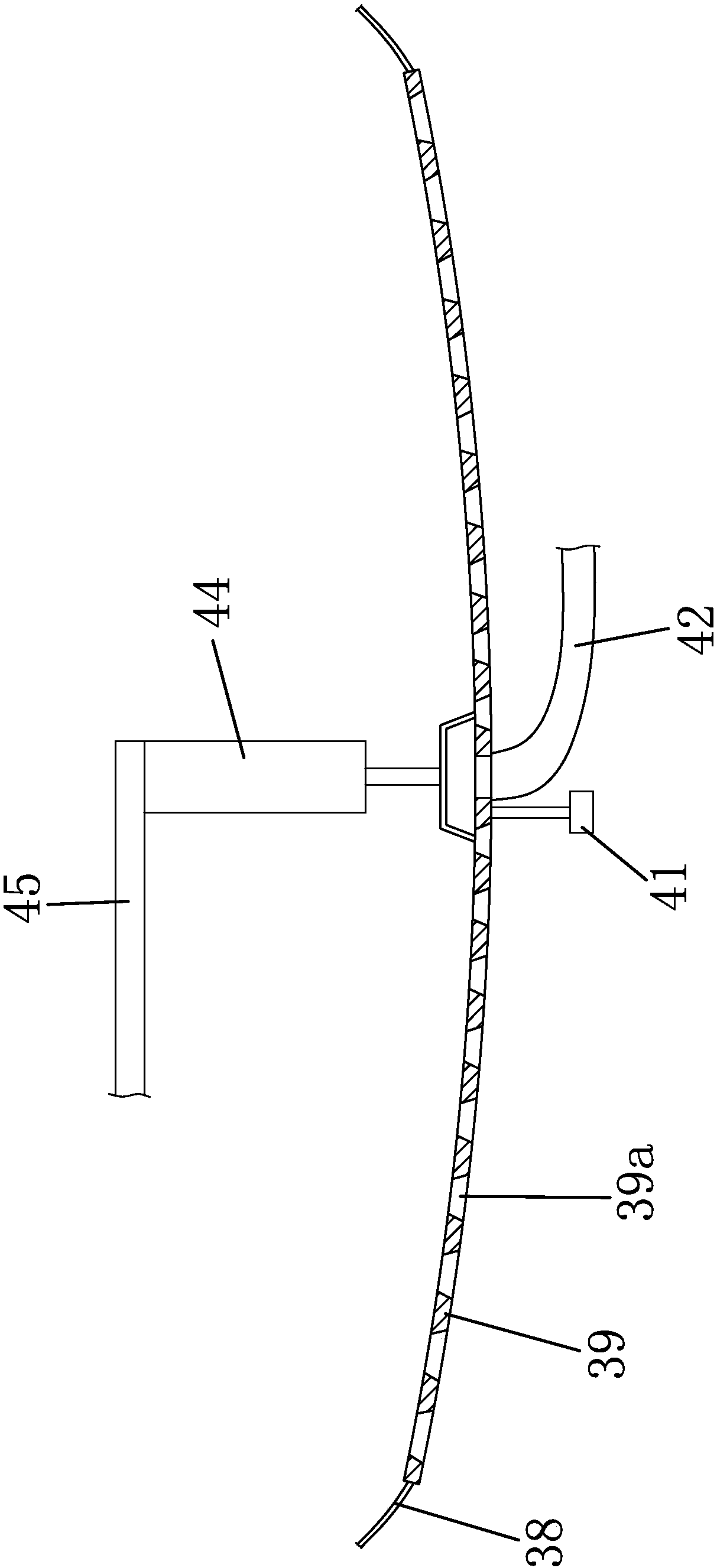

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0050] The printing method of the improved cotton fabric comprises the following steps:

[0051] a. Sizing: pretreat cotton fabrics with sizing;

[0052] b. Printing: Spray reactive dye gravure ink directly onto the film to form a pattern, and then transfer the pattern on the film to the sized cotton fabric;

[0053] c. Steaming: put the printed cotton fabric into a steam box for steaming, the steaming time is 8-12min, and the steaming temperature is 100-106°C; in this embodiment, the printed cotton fabric is The fabric is put into a steam box for steaming, the steaming time is 9 minutes, and the steaming temperature is 102°C;

[0054] d. Cooling: After cooling to room temperature, tear off the film on the cotton fabric;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com