Formaldehyde-free color fixing agent for acid dyes and preparation method thereof

A formaldehyde-free color-fixing agent and acid dye technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as poor wet rubbing fastness and washing fastness, influence of fabric shade and hand feeling, complex synthesis equipment and process, etc. , to achieve the effect of improving dry and wet fastness, improving dry rubbing fastness, and no formaldehyde pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of the aldehyde-free color-fixing agent for acid dyes of the present invention is realized through the following steps:

[0027] (1) Add hydroxypropyltrimethylammonium chloride chitosan, acrylate containing amino structure, unsaturated carboxylate monomer, desalted water into the stirred polymerization reactor, start stirring, and start heating ;

[0028] (2) When the temperature in the stirring type polymerization reactor rises to 95 ℃ ~ 130 ℃, start dropping the initiator solution whose mass concentration is 1 ~ 10%. It is prepared from salt water, and the dropping time is controlled within 3 to 6 hours;

[0029] (3) After the dropwise addition, keep the temperature and continue the reaction for 1 to 3 hours, then cool down and discharge the material to obtain the color fixing agent.

Embodiment 1

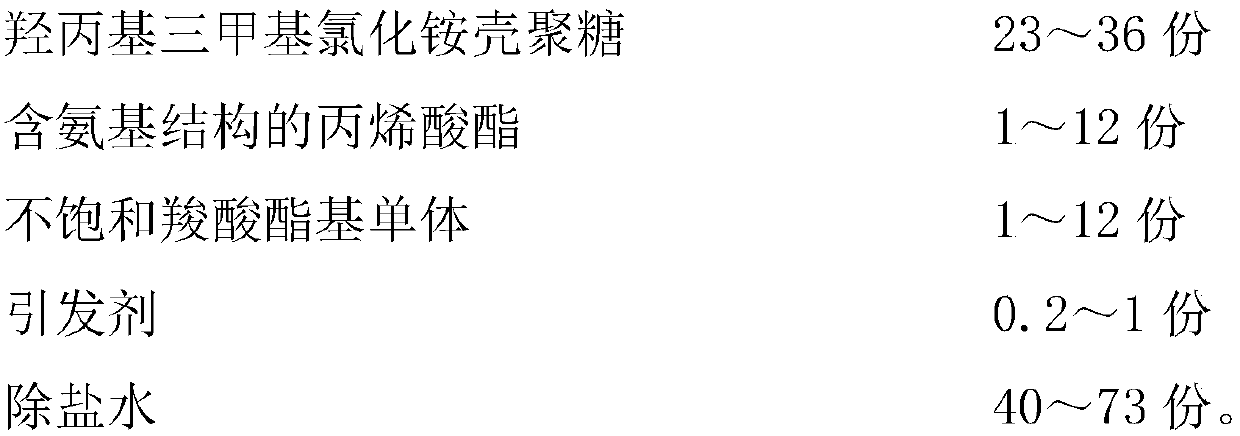

[0032] A kind of formaldehyde-free color-fixing agent for acid dyes of the present invention is made of the following raw material components in proportions by mass:

[0033]

[0034] A kind of preparation method of the aldehyde-free color-fixing agent for acid dyes of the present invention is realized through the following steps:

[0035] (1) Add 23.5 parts of hydroxypropyltrimethylammonium chloride chitosan, 1.5 parts of aminoethyl acrylate, 1.2 parts of methyl acrylate, 63.8 parts of desalinated water into the stirred polymerization reactor, start stirring, and start heating heat up;

[0036] (2) When the temperature in the stirring type polymerization reactor rose to 97 DEG C, it was 9.3% ammonium persulfate solution that began to drop the mass concentration, and this ammonium persulfate solution was prepared by 0.93 parts of ammonium persulfate and 9.07 parts of demineralized water into, the dropping time is controlled at 3.3 hours;

[0037] (3) After the dropwise ad...

Embodiment 2

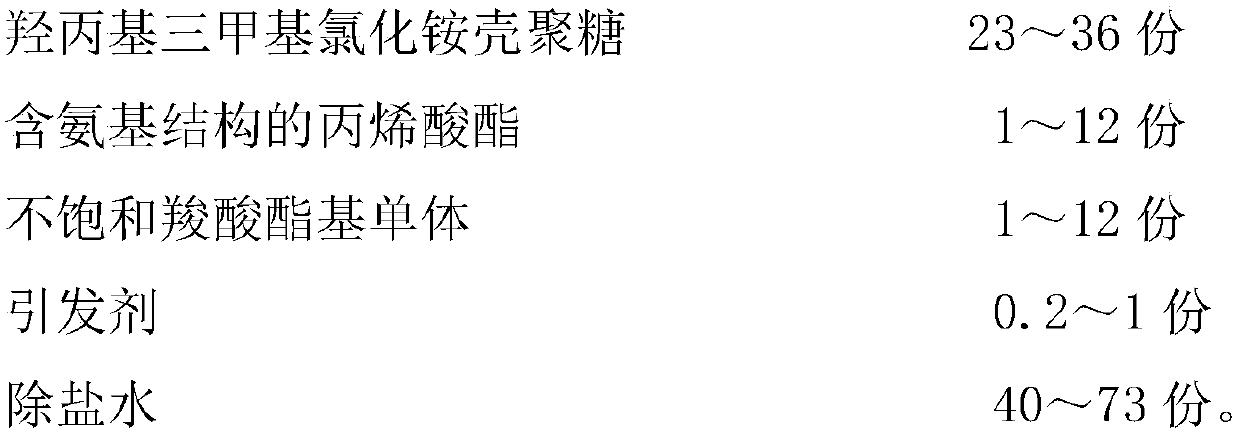

[0039] A kind of formaldehyde-free color-fixing agent for acid dyes of the present invention is made of the following raw material components in proportions by mass:

[0040]

[0041] A kind of preparation method of the aldehyde-free color-fixing agent for acid dyes of the present invention is realized through the following steps:

[0042] (1) Add 25 parts of hydroxypropyltrimethylammonium chloride chitosan, 3 parts of aminopropyl acrylate, 3.1 parts of ethyl acrylate, and 58.9 parts of desalinated water into the stirred polymerization reactor, start stirring, and start heating heat up;

[0043] (2) When the temperature in the stirring type polymerization reactor rose to 103 DEG C, it was 3.3% ammonium persulfate solution to start dripping mass concentration, and this ammonium persulfate solution was prepared by 0.33 parts of ammonium persulfate and 9.67 parts of demineralized water into, the dropping time is controlled at 5 hours;

[0044] (3) After the dropwise addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com