Textile printing and dyeing fixer and preparation method thereof

A color-fixing agent and textile technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of low wet rubbing fastness and low utilization rate of dyed fabrics, and improve dry rubbing fastness and quality , High color fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of textile printing and dyeing fixing agent of the present invention, realizes by following steps:

[0028] (1) Put the cationic monomer, 1,3-diallylamino-2-hydroxypropane, (meth)acrylate monomer containing isocyanate group and water into the polymerization reaction vessel, stir evenly, and heat heat up;

[0029] (2) Under anaerobic conditions and stirring conditions, drip initiator solution in the polymerization reaction vessel, carry out polymerization reaction, the temperature of polymerization reaction is 80~100 ℃, and the mass concentration of initiator solution is 1~10%, here The initiator solution is prepared from the initiator and part of the water, and the initiator solution is dripped within 1 to 3 hours;

[0030] (3) After the dropwise addition is completed, continue to carry out the polymerization reaction at the temperature of the polymerization reaction for 1 to 3 hours, then cool down to room temperature and discharge to obta...

Embodiment 1

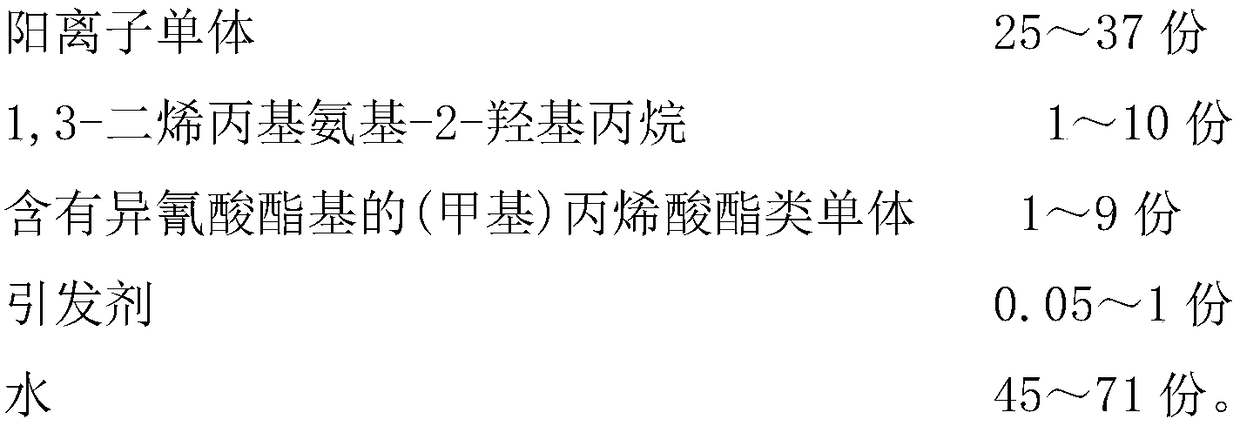

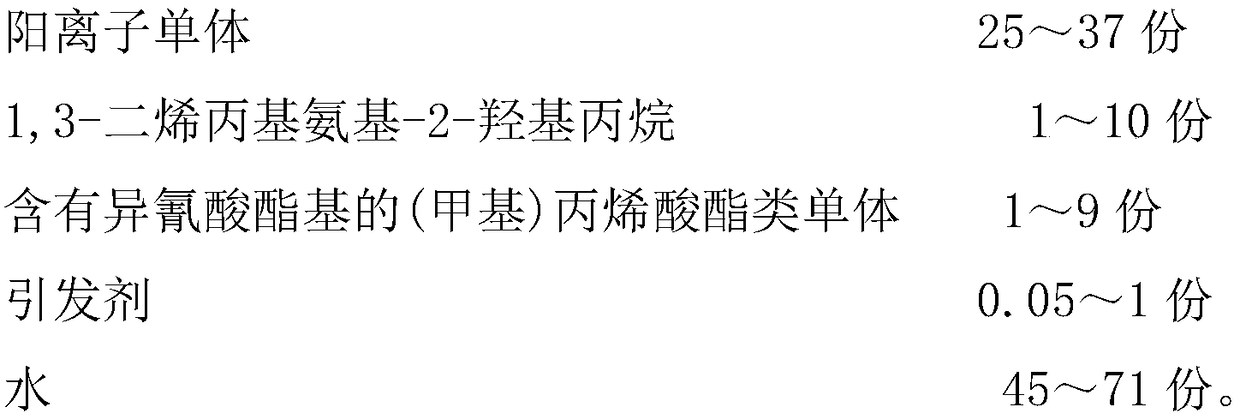

[0033] A kind of textile printing and dyeing fixing agent of the present invention is made of the following raw material components with the ratio of parts by mass:

[0034]

[0035] A kind of preparation method of textile printing and dyeing fixing agent of the present invention, realizes by following steps:

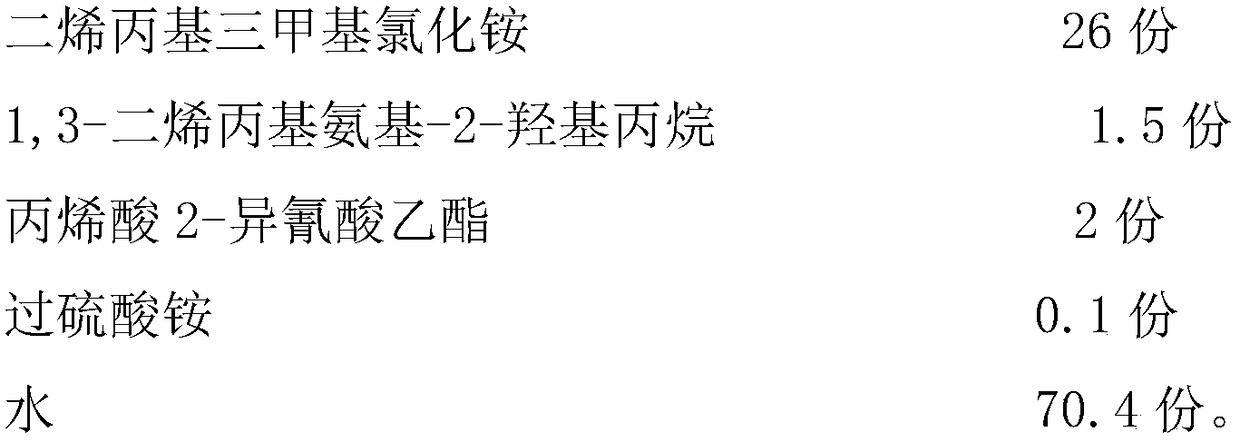

[0036] (1) Put 26 parts of diallyltrimethylammonium chloride, 1.5 parts of 1,3-diallylamino-2-hydroxypropane, 2 parts of 2-isocyanate ethyl acrylate, and 65.4 parts of water into In the polymerization reaction vessel, stir evenly, and heat up;

[0037] (2) Under anaerobic conditions and stirring conditions, add ammonium persulfate solution dropwise to the polymerization reaction vessel to carry out polymerization reaction. The temperature of the polymerization reaction is 82 ° C, and the mass concentration of ammonium persulfate solution is 2%. The ammonium solution is prepared from 0.1 part of ammonium persulfate and 4.9 parts of water, and the dropping time is con...

Embodiment 2

[0040] A kind of textile printing and dyeing fixing agent of the present invention is made of the following raw material components with the ratio of parts by mass:

[0041]

[0042] A kind of preparation method of textile printing and dyeing fixing agent of the present invention, realizes by following steps:

[0043] (1) Put 28 parts of methyl diallyl ammonium chloride, 3 parts of 1,3-diallylamino-2-hydroxypropane, 2.5 parts of 2-isocyanate ethyl methacrylate, and 56.5 parts of water into Into the polymerization reaction vessel, stir evenly, and heat up;

[0044] (2) Under anaerobic conditions and stirring conditions, add ammonium persulfate solution dropwise to the polymerization reaction vessel to carry out polymerization reaction. The temperature of the polymerization reaction is 86 ° C, and the mass concentration of ammonium persulfate solution is 3%. The ammonium solution is prepared from 0.3 parts of ammonium persulfate and 9.7 parts of water, and the dropping time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com