Preparation method of formaldehyde-free color fixative

An aldehyde-free color-fixing agent and color-fixing agent technology, which is used in the field of textile dyeing and fabric fixing, and the color-fixing field of sensitive color dyes. The effect of wet rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

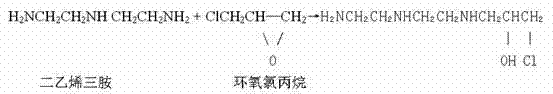

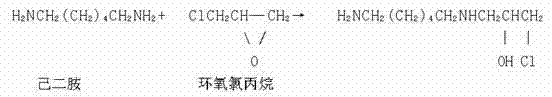

Method used

Image

Examples

Embodiment 1

[0026] Add a certain amount of diethylenetriamine, part of hexamethylenediamine (accounting for 25-35% of the total amount of hexamethylenediamine) and deionized water into the four-necked flask, and heat up to 60°C-65°C while stirring, slowly Add a certain amount of epichlorohydrin dropwise for addition reaction, the dropwise addition time is 2-3h, and the dropwise addition is completed; continue the heat preservation reaction for 30-40min, drop the remaining hexamethylenediamine solution, dropwise time After completion, continue to keep warm for 3-4 hours, pass the test, cool down to below 40°C, add a certain amount of hydrochloric acid to adjust the pH value to 5-6, and finally obtain a color-fixing agent with a solid content of about 35%.

[0027] During the preparation process, the molar ratio of diethylenetriamine to hexamethylenediamine is 1:1.2-1:1.7, and the molar ratio of epichlorohydrin to total amines is 1:1-1:3.

[0028] The characteristics of the fixing agent pre...

Embodiment 2

[0036] The difference between this example and Example 1 is that dimethylamine is used instead of diethylenetriamine, and the molar ratio of dimethylamine to hexamethylenediamine is 1:1.2.

Embodiment 3

[0038] The difference between this example and Example 1 is that triethylenetetramine is used instead of diethylenetriamine, and the molar ratio of triethylenetetramine to hexamethylenediamine is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com