Cationic formaldehyde-free color fixing agent and preparation method thereof

A color-fixing agent, cationic technology, applied in the field of cationic formaldehyde-free color-fixing agent and its preparation, can solve the problems affecting soaping fastness, unsatisfactory rubbing fastness, etc. degree, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of a cationic formaldehyde-free color fixing agent of the present invention is realized through the following steps:

[0028] (1) Put a certain amount of water and chitosan quaternary ammonium salt into a four-necked reaction flask, and heat it to 85-120°C with an oil bath under the protection of nitrogen;

[0029] (2) Add dropwise the mixed solution of 6-allylamino n-hexyltrimethylammonium chloride, sugar-containing monomer and water respectively, and add dropwise the initiator solution whose mass concentration is 1%~3% in addition, this initiator The solution is prepared from the initiator and water;

[0030] (3) Control the mixed solution of 6-allylamino n-hexyltrimethylammonium chloride, sugar-containing monomer and water and the initiator solution to add simultaneously, and the dropping time is controlled at 3 to 6 hours;

[0031] (4) After the dropwise addition, keep the temperature and continue the reaction for 1 to 3 hours, then cool down...

Embodiment 1

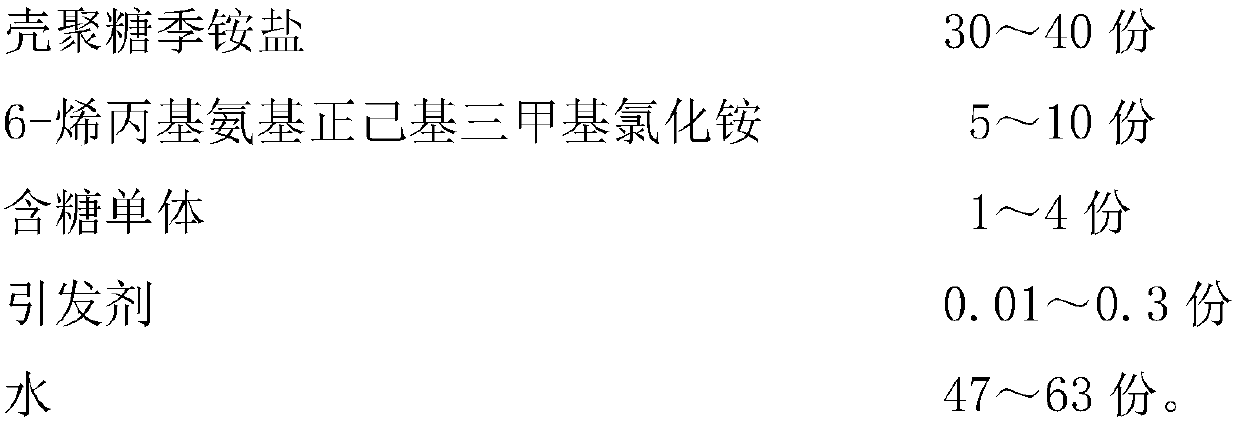

[0034] A cationic formaldehyde-free color-fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0035]

[0036]

[0037] The preparation method of a cationic formaldehyde-free color fixing agent of the present invention is realized through the following steps:

[0038] (1) Put 51.3 parts of water and 31 parts of N-chitosan quaternary ammonium salt into a four-necked reaction flask, and heat it to 88°C with an oil bath under nitrogen protection;

[0039] (2) Add dropwise a mixed solution of 5.5 parts of 6-allylamino-n-hexyltrimethylammonium chloride, 1.2 parts of 3-O-methacryloyl-diacetone-D-glucose and 10 parts of water, and drop Add mass concentration and be the initiator solution of 2%, this initiator solution is configured by 0.02 part of ammonium persulfate and 0.98 part of water;

[0040] (3) control 6-allylamino n-hexyltrimethylammonium chloride, the mixed solution of sugar-containing monomer and water and...

Embodiment 2

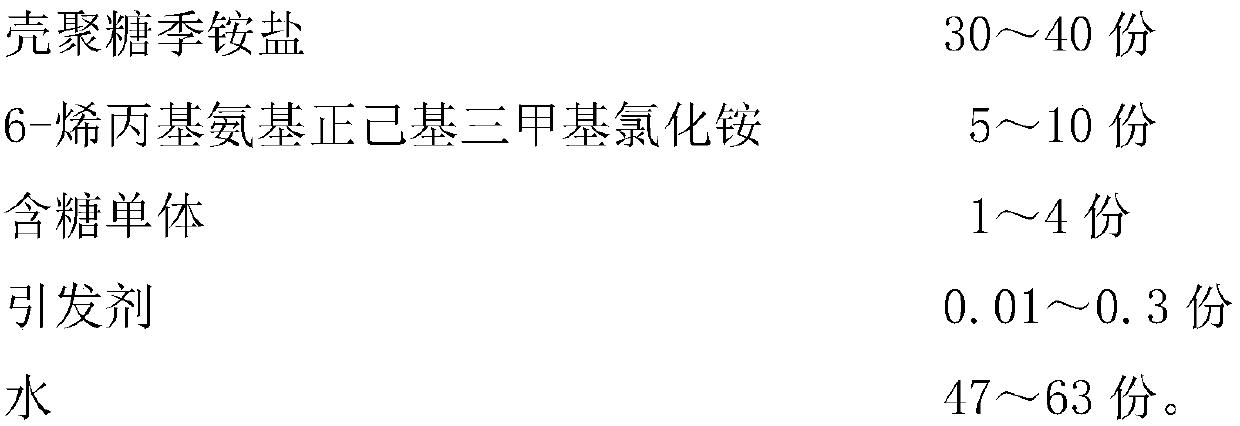

[0043] A cationic formaldehyde-free color-fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0044]

[0045] The preparation method of a cationic formaldehyde-free color fixing agent of the present invention is realized through the following steps:

[0046] (1) Put 42.9 parts of water and 33 parts of N-chitosan quaternary ammonium salt into a four-necked reaction flask, and heat it to 90°C with an oil bath under nitrogen protection;

[0047] (2) Add dropwise the mixed solution of 6.5 parts of 6-allylamino n-hexyltrimethylammonium chloride, 1.6 parts of 6-O-methacryloyl-dipropylene-D-galactose and 12 parts of water respectively, and Dropping mass concentration is the initiator solution of 2%, and this initiator solution is formulated by 0.08 part of ammonium persulfate and 3.92 parts of water;

[0048] (3) control the mixed solution and initiator solution of 6-allylamino n-hexyl trimethylammonium chloride, 6-O-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com