Quaternary ammonium salt cationic color fixing agent and preparation method thereof

A technology of quaternary ammonium salt cation and color-fixing agent, applied in dyeing, textile and papermaking, etc., can solve the problems of products not meeting environmental protection requirements and import requirements, and achieve improved dry rubbing fastness, improved quality, and little impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of quaternary ammonium salt cationic color-fixing agent of the present invention, realize by following steps:

[0031] (1) Add long-chain alkyl quaternary ammonium salt, organic acid amide, water in the reaction vessel that thermometer, oil bath, stirrer are housed, start stirring, and start to heat up;

[0032] (2) When the temperature in the reaction vessel rises to 85-120°C, start to drop the mixed solution of (meth)acrylate monomer with amino group, initiator and water, and control the mixed solution within 3-6 hours Drip finished;

[0033] (3) After the dropwise addition, keep the temperature and continue the reaction for 1 to 3 hours, then cool down and discharge the material to obtain the color fixing agent.

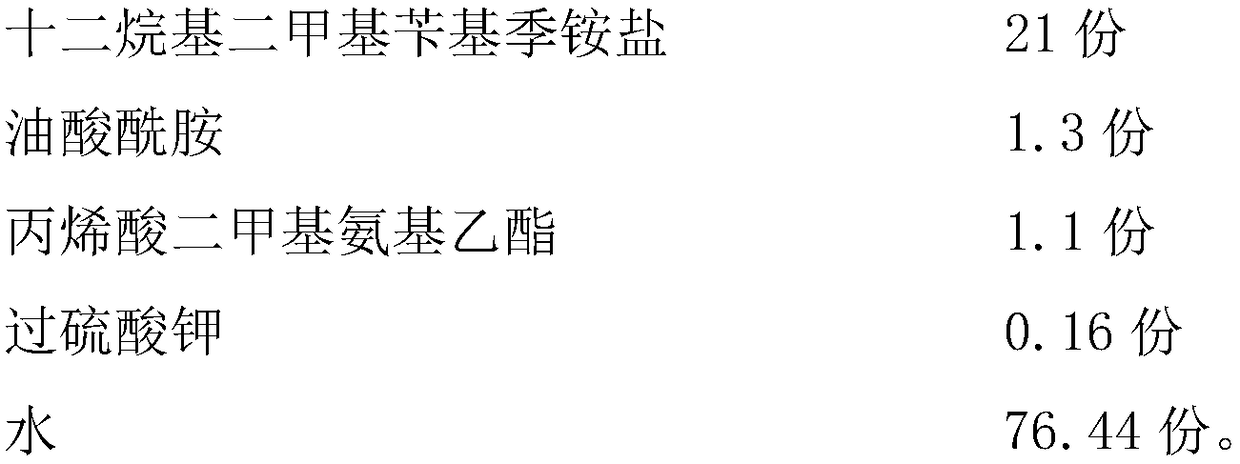

Embodiment 1

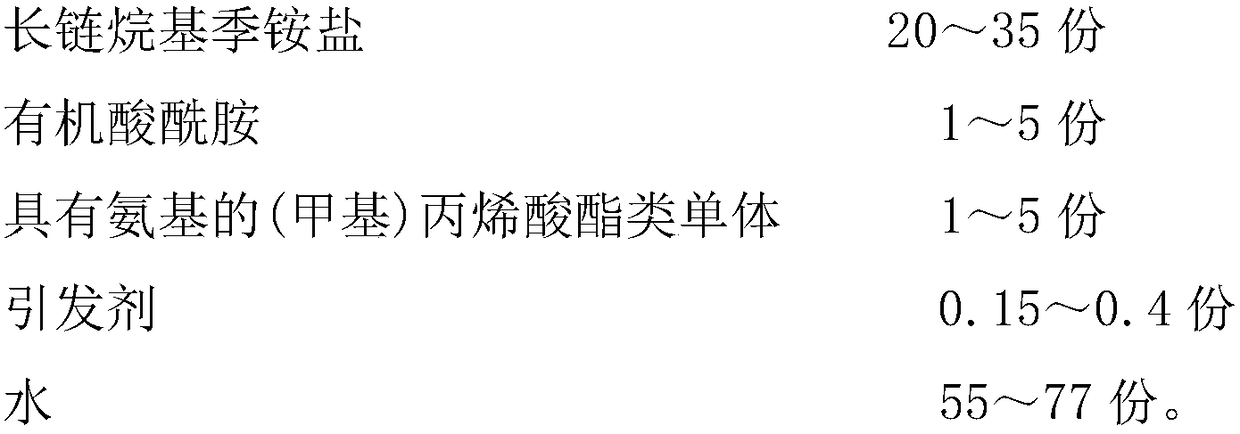

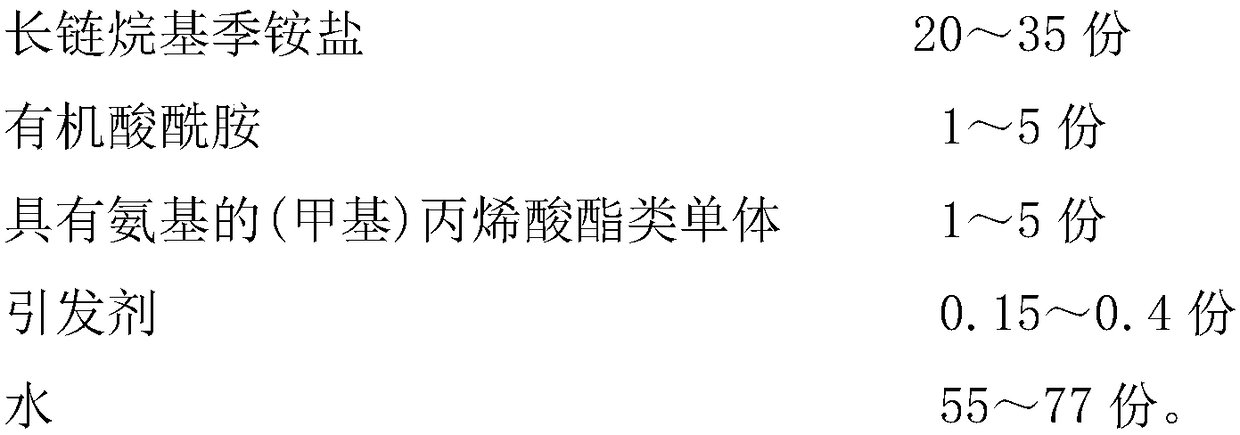

[0036] A quaternary ammonium salt cationic color-fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0037]

[0038] A kind of preparation method of quaternary ammonium salt cationic color-fixing agent of the present invention, realize by following steps:

[0039] (1) Add 21 parts of dodecyldimethylbenzyl quaternary ammonium salt, 1.3 parts of oleic acid amide, 66.6 parts of water in the reaction vessel equipped with thermometer, oil bath and stirrer, start stirring, and start heating up;

[0040] (2) When the temperature in the reaction vessel rose to 88°C, a mixed solution of 1.1 parts of dimethylaminoethyl acrylate, 0.16 parts of potassium persulfate and 9.84 parts of water was added dropwise, and the mixed solution was controlled to drop within 3.5 hours ;

[0041] (3) After the dropwise addition, keep the temperature and continue the reaction for 1.1 hours, then cool down and discharge the material to obtai...

Embodiment 2

[0043] A quaternary ammonium salt cationic color-fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0044]

[0045] A kind of preparation method of quaternary ammonium salt cationic color-fixing agent of the present invention, realize by following steps:

[0046] (1) Add 24 parts of dodecyl trimethyl quaternary ammonium salt, 1.8 parts of benzoic acid amide, 62.6 parts of water in the reaction vessel equipped with thermometer, oil bath and stirrer, start stirring, and start to heat up ;

[0047] (2) When the temperature in the reaction vessel rose to 92°C, a mixed solution of 1.6 parts of diethylaminoethyl acrylate, 0.2 parts of potassium persulfate and 9.8 parts of water was added dropwise, and the mixed solution was controlled to be dripped within 3.7 hours ;

[0048] (3) After the dropwise addition, keep the temperature and continue to react for 1.5 hours, then cool down and discharge the material to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com