Rapid dyeing method for superfine fiber suede leather

A technology of superfine fiber and suede, which is applied in dyeing, textiles and papermaking, etc., can solve problems such as poor color fastness and heavy metal pollution, and achieve the effect of improving wet rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Immerse the superfine fiber synthetic leather in the treatment liquid, pad and pad, the liquid-carrying rate of the microfiber leather is 50%; dry after padding, and carry out conventional dyeing on the dried microfiber suede leather.

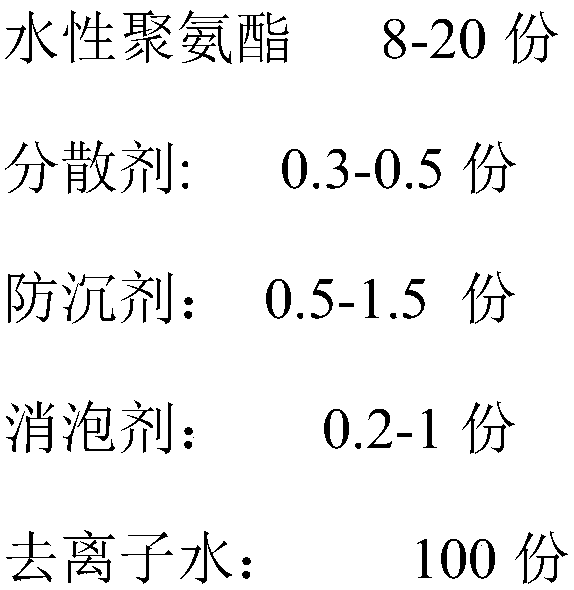

[0020] The treatment liquid includes the following components in parts by weight:

[0021]

[0022] The preparation method is as follows:

[0023] Slowly add dispersant, anti-sedimentation agent, and defoamer to deionized water under high-speed dispersion and mix evenly, then add water-based polyurethane to it and tell emulsification to obtain the treatment liquid;

[0024] The color fastness of the obtained microfiber leather is ≥3-4 grade for dry rubbing, and ≥2-3 grade for wet rubbing.

Embodiment 2

[0026] Immerse the superfine fiber synthetic leather in the treatment liquid, and pad it. The liquid-carrying rate of the microfiber leather is 70%. After the padding, it is dried, and the superfiber suede leather after drying is subjected to conventional dyeing.

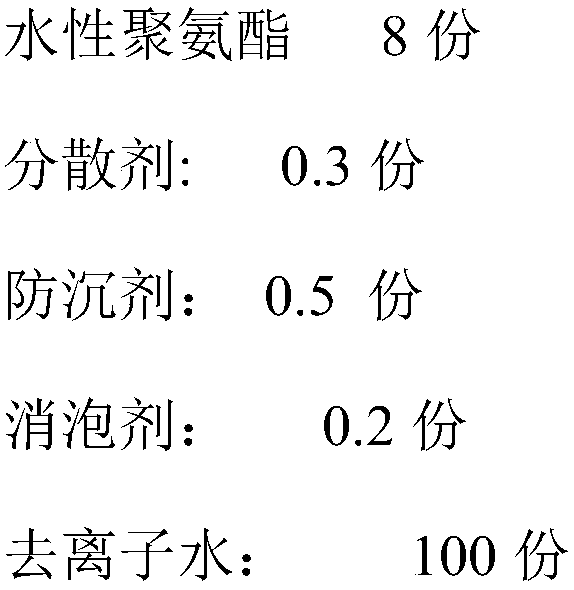

[0027] The treatment liquid includes the following components in parts by weight:

[0028]

[0029] The preparation method is as follows:

[0030] Slowly add dispersant, anti-sedimentation agent, and defoamer to deionized water under high-speed dispersion and mix evenly, then add water-based polyurethane to it and tell emulsification to obtain the treatment liquid;

[0031] The color fastness of the obtained microfiber leather is ≥5 grades for dry rubbing, and ≥3-4 grades for wet rubbing.

Embodiment 3

[0033] The microfiber synthetic leather is immersed in the treatment liquid, and the superfiber suede leather is subjected to conventional dyeing after padding.

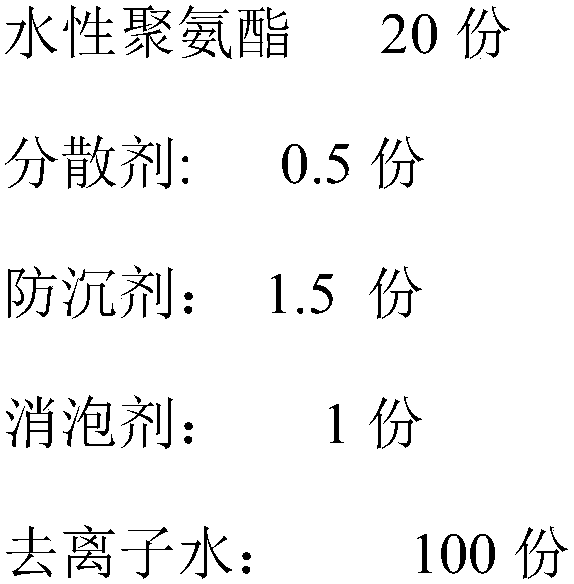

[0034] The treatment liquid includes the following components in parts by weight:

[0035]

[0036]

[0037] The preparation method is as follows:

[0038] Slowly add dispersant, anti-sedimentation agent, and defoamer to deionized water under high-speed dispersion and mix evenly, then add water-based polyurethane to it and tell emulsification to obtain the treatment liquid;

[0039] The color fastness of the obtained microfiber leather is ≥4 for dry rubbing and ≥3 for wet rubbing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com