A kind of dry rubbing fastness improving agent of textile dyeing and its preparation method and dry rubbing fastness improving process

A technology for fastness improvement and textiles, which is applied in the dry rubbing fastness improvement process and the preparation process of dry rubbing fastness improver for textile dyed matter. Improve dry rubbing fastness and slow down the effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

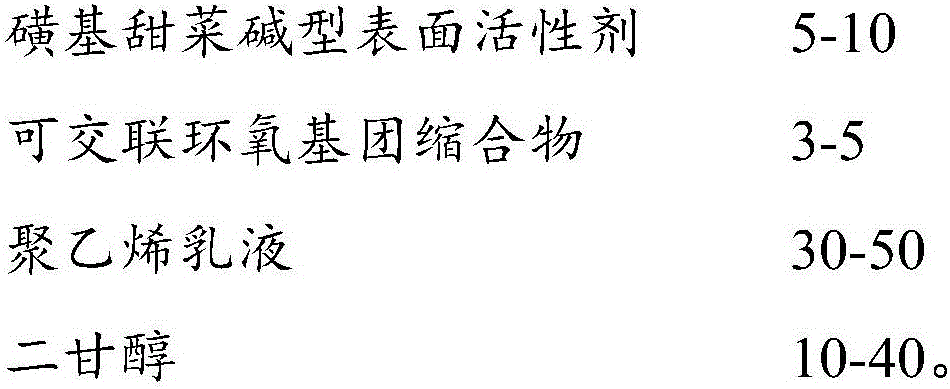

Method used

Image

Examples

Embodiment 1

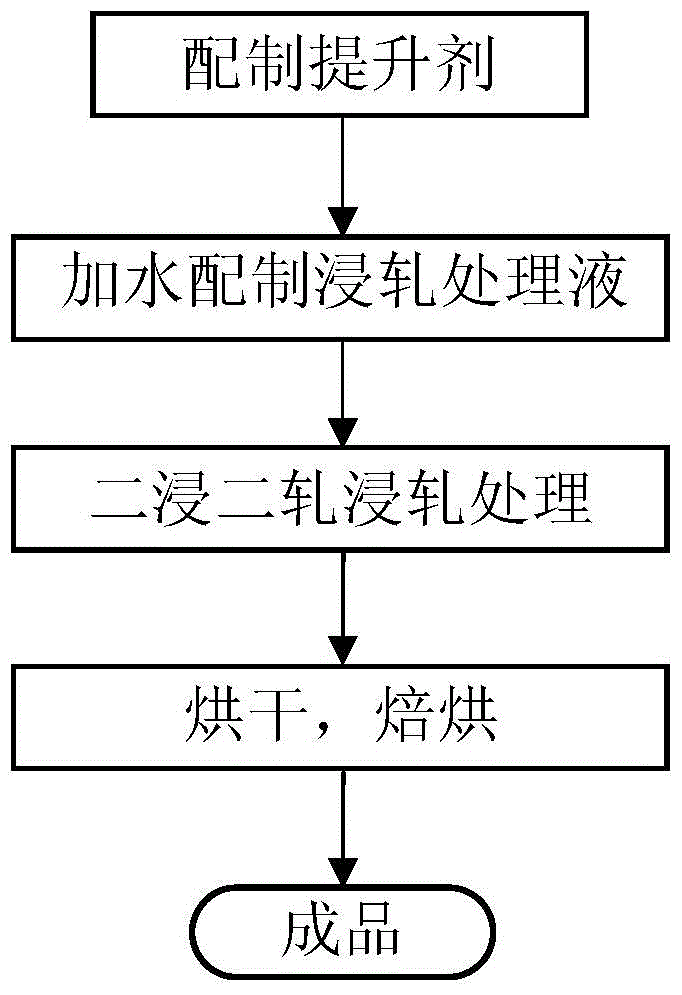

[0056] Select the lifting agent of Example 1 in the first group of dry rubbing fastness improving agent embodiments, and the treatment process adopts a padding process, and the described dry rubbing fastness improving agent is added with water to be mixed with a concentration of 30g / L padding treatment solution , into the padding tank.

[0057] Textiles are subjected to the padding process of two dipping and two rolling, the liquid rate is 90%, pre-dried, baked at 130°C for 2 minutes, and the padding treatment is completed to obtain the superfiber scarlet fabric treated with the dry rubbing fastness improving agent.

[0058] Of course, the curing temperature and curing time can be appropriately adjusted according to the variety and quality of the textiles, as long as the padding effect of the agent treatment solution is solidified and improved through the curing process.

[0059] The superfiber scarlet fabric treated with the dry rubbing fastness enhancer was tested on the dry...

Embodiment 2

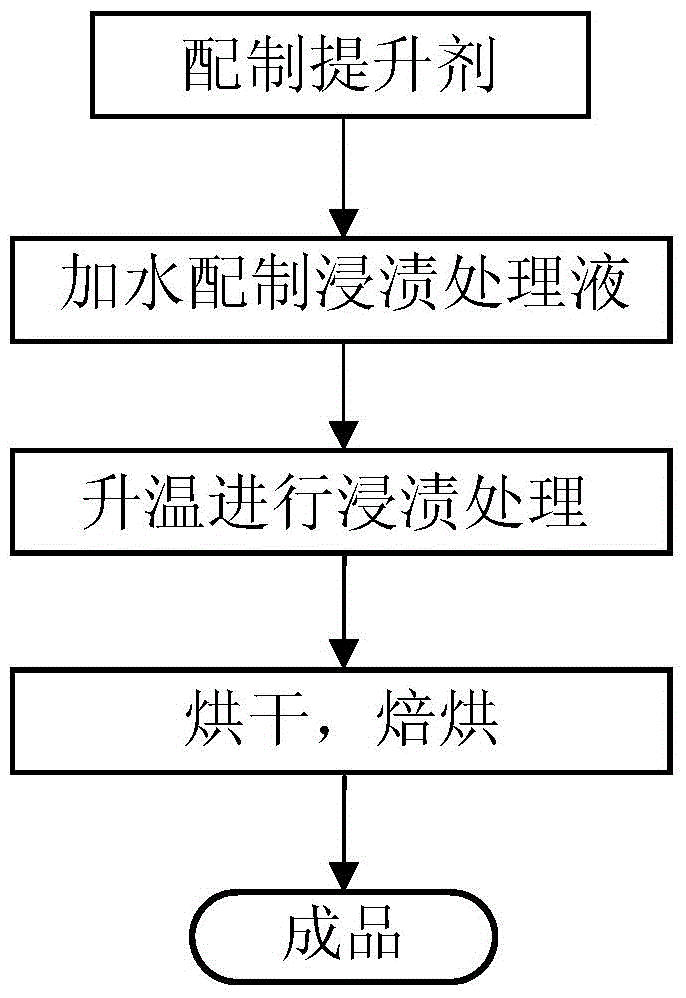

[0061] The improving agent of Example 1 in the first group of dry rubbing fastness improving agent embodiments is selected, the treatment process adopts the dipping method, and the dosage of the dry rubbing fastness improving agent is prepared according to 3% of the weight of the fabric to be treated.

[0062] Add water to configure the impregnating treatment solution, using a bath ratio of 1:20, add the fabric to the impregnating treatment solution at room temperature, raise the temperature to 50°C, and treat for 30 minutes. Take it out and dry it, then bake it at 130°C for 2 minutes.

[0063] Of course, the curing temperature and curing time can be properly adjusted according to the variety and quality of textiles, as long as the impregnation effect of the agent treatment solution is solidified and improved through the curing process.

[0064] The silk fabrics treated with dry rubbing fastness enhancer were tested on a rubbing fastness tester. The dry rubbing fastness of un...

Embodiment 3

[0066] The improving agent of Example 1 in the first group of dry rubbing fastness improving agent embodiments is selected, the treatment process adopts the dipping method, and the dosage of the dry rubbing fastness improving agent is prepared according to 5% of the weight of the fabric to be treated.

[0067] Add water to prepare the dipping treatment solution, the bath ratio is 1:10, add the fabric to the dipping treatment solution at room temperature, raise the temperature to 60°C, and treat for 30 minutes. Take it out and dry it at 130°C for 2 minutes.

[0068] The woolen fabrics treated with dry rubbing fastness enhancer were tested on a rubbing fastness tester. The dry rubbing fastness of untreated rough wool fabric (black) is grade 2, and the dry rubbing fastness of wool wool fabric (black) after the impregnation treatment is grade 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com