Pigment printing process

A pigment printing and crafting technology, which is applied in the textile field, can solve the problems of hard hand feeling, knotted printed cloth panel, poor scrubbing and rubbing fastness of printed products, etc., and achieves the advantages of less dosage, fine lines, good hand feeling and color quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Coating preparation:

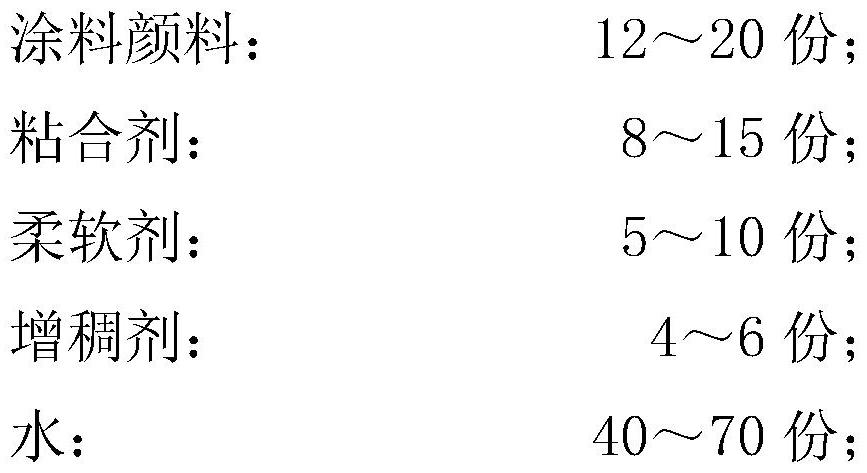

[0038] Take the following raw materials according to parts by weight:

[0039]

[0040] (2) Sizing: Mix 8111 Scarlet FFG obtained in step (1), adhesive, softener HK-T50, and water evenly, and add thickener TF313E under stirring conditions to obtain a coating slurry;

[0041] (3) Use the paint slurry obtained in step (2) to print on the fabric, and then bake and fix the color at 90° C. for 2 minutes to complete the paint printing process.

[0042] Wherein, the preparation method of adhesive is as follows:

[0043] (1) The modified sodium alginate product is obtained by amidation reaction of taurine and sodium alginate in a ratio of 1:5, and mixed uniformly as the water phase; the catalyst used is 1-ethyl- (3-dimethylaminopropyl) carbodiimide hydrochloride and N-hydroxyl succinimide, the catalyst accounts for 5% of the total mass of taurine and sodium alginate mixture; react at pH6. 5 in phosphate buffered saline solution;

[0044] (2) Th...

Embodiment 2

[0047] (1) Coating preparation:

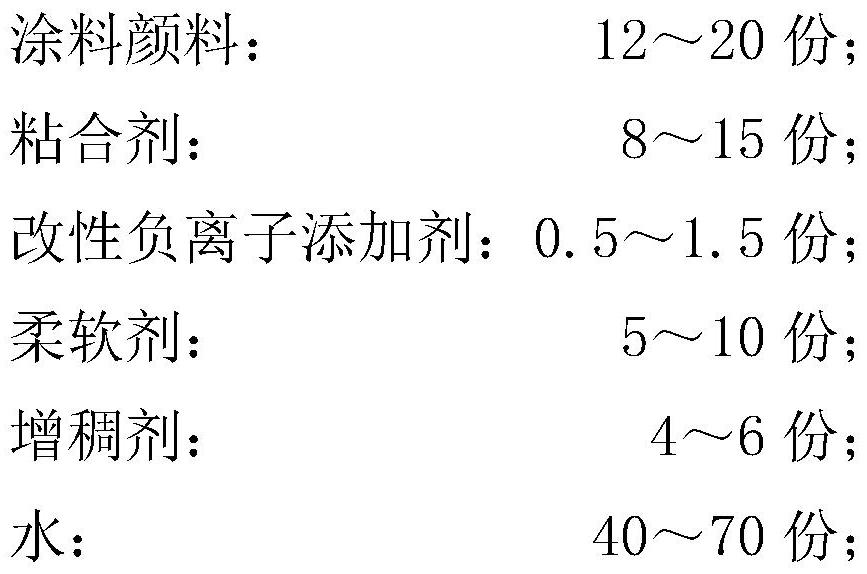

[0048] Take the following raw materials according to parts by weight:

[0049]

[0050] (2) Sizing: Mix 8111 Scarlet FFG obtained in step (1), adhesive, softener HK-T50, and water evenly, and add thickener TF313E under stirring conditions to obtain a coating slurry;

[0051] (3) Use the paint slurry obtained in step (2) to print on the fabric, and then bake and fix the color at 160° C. for 30 minutes to complete the paint printing process.

[0052] Wherein, the preparation method of adhesive is as follows:

[0053] (1) The modified sodium alginate product is obtained by amidation reaction of taurine and sodium alginate in a ratio of 2:5, and mixed uniformly as the water phase; the catalyst used is 1-ethyl- (3-dimethylaminopropyl) carbodiimide hydrochloride and N-hydroxyl succinimide, the catalyst accounts for 8% of the total mass of taurine and sodium alginate mixture; react at pH6. 5 in phosphate buffered saline solution;

[0054] (2) ...

Embodiment 3

[0057] (1) Coating preparation:

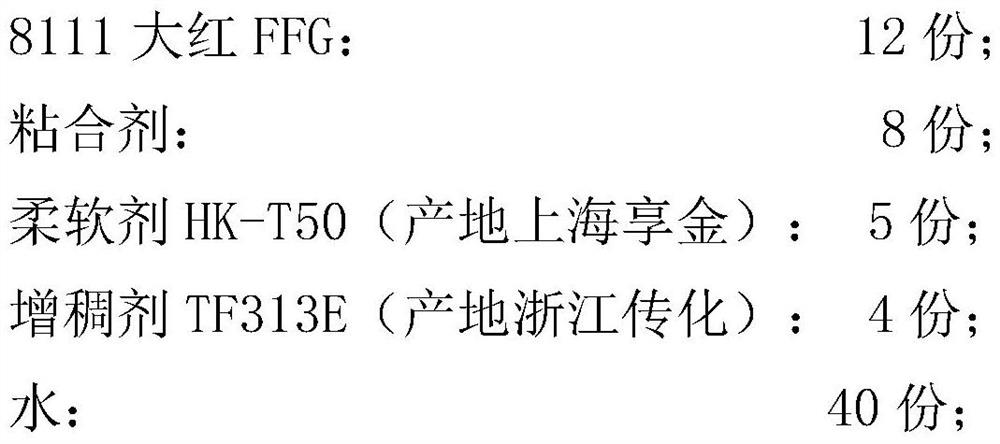

[0058] Take the following raw materials according to parts by weight:

[0059]

[0060]

[0061] (2) Sizing: Mix 8111 Scarlet FFG obtained in step (1), adhesive, softener HK-T50, and water evenly, and add thickener TF313E under stirring conditions to obtain a coating slurry;

[0062] (3) Use the paint slurry obtained in step (2) to print on the fabric, and then bake and fix the color at a temperature of 110° C. for 10 minutes to complete the paint printing process.

[0063] Wherein, the preparation method of adhesive is as follows:

[0064] (1) The modified sodium alginate product is obtained by amidation reaction of taurine and sodium alginate in a ratio of 2:5, and mixed uniformly as the water phase; the catalyst used is 1-ethyl-alginate with a ratio of 2:3 (3-dimethylaminopropyl) carbodiimide hydrochloride and N-hydroxysuccinimide, the catalyst accounts for 6% of the total mass of taurine and sodium alginate mixture; react at pH6. 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com