A kind of modified carboxymethyl starch polymer and its preparation method and application

A technology of carboxymethyl starch and polymer, which is applied in the field of modified carboxymethyl starch polymer and its preparation, can solve the problems of unsatisfactory color fastness, low wet fastness and unsatisfactory effect, etc. Wet fastness, improvement of dry rubbing fastness, little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

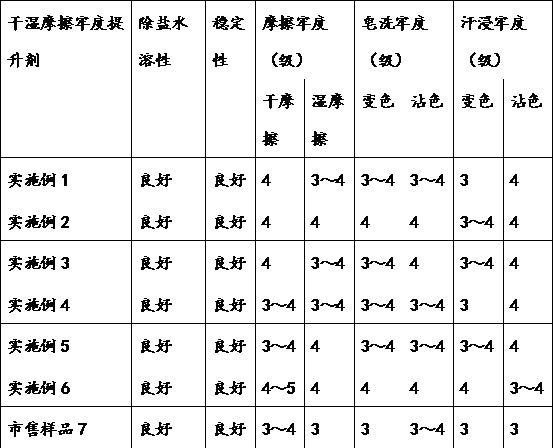

Examples

Embodiment 1

[0026] A kind of preparation method of modified carboxymethyl starch polymer, comprises the steps:

[0027] a. Raw material preparation: in parts by mass, 34 parts of carboxymethyl starch, 1.5 parts of hexanediol divinyl ether, 1.3 parts of vinyl isocyanate, 2.6 parts of epichlorohydrin, 0.22 parts of ammonium persulfate, 61.86 parts of demineralized water ;

[0028] b. Carboxymethyl starch was modified at a low temperature for 22 minutes in a low temperature plasma reactor, and the temperature was set at -8°C;

[0029] c. Add 1.5 parts of hexanediol divinyl ether, 1.3 parts of vinyl isocyanate, and 52.08 parts of desalted water to the low-temperature modified carboxymethyl starch, stir and start heating;

[0030] d. When the temperature rises to 112°C, start to drop the initiator solution with a mass concentration of 2.2%. The initiator solution is prepared from 0.22 parts of ammonium persulfate and the remaining desalinated water, and the dropping time is controlled at 2 ho...

Embodiment 2

[0033] A kind of preparation method of modified carboxymethyl starch polymer, comprises the steps:

[0034] a. Raw material preparation: in parts by mass, 36 parts of carboxymethyl starch, 2 parts of neopentyl glycol divinyl ether, 2.2 parts of vinyl isocyanate, 3.4 parts of epichlorohydrin, 0.34 parts of ammonium persulfate, 60.3 parts of demineralized water share;

[0035] b. Carboxymethyl starch was modified at a low temperature for 22 minutes in a low temperature plasma reactor, and the temperature was set at -8°C;

[0036] c. Add 2 parts of neopentyl glycol divinyl ether, 2.2 parts of vinyl isocyanate, and 50.64 parts of desalted water to the carboxymethyl starch modified at low temperature, stir and start heating;

[0037] d. When the temperature rises to 117°C, start to drop the initiator solution with a mass concentration of 3.4%. The initiator solution is prepared from 0.34 parts of ammonium persulfate and the remaining desalinated water, and the dropping time is con...

Embodiment 3

[0040] A kind of preparation method of modified carboxymethyl starch polymer, comprises the steps:

[0041] a. Raw material preparation: in parts by mass, 37.2 parts of carboxymethyl starch, 2.2 parts of tetraethylene glycol divinyl ether, 2.3 parts of vinyl isocyanate, 4.1 parts of epichlorohydrin, 0.48 parts of sodium persulfate, 58.32 parts of demineralized water share;

[0042] b. Carboxymethyl starch was modified at a low temperature for 22 minutes in a low temperature plasma reactor, and the temperature was set at -8°C;

[0043] c. Add 2.2 parts of tetraethylene glycol divinyl ether, 2.3 parts of vinyl isocyanate, and 48.8 parts of desalted water to the carboxymethyl starch modified at low temperature, stir and start heating;

[0044] d. When the temperature rises to 119°C, start to drop the initiator solution with a mass concentration of 4.8%. The initiator solution is prepared from 0.48 parts of sodium persulfate and the remaining desalinated water, and the dropping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com