A kind of pigment printing fabric dry rubbing fastness improving agent and its preparation and use method

A technology for improving fastness and pigment printing, applied in the field of textile pigment printing, can solve the problems of reduced dry rubbing fastness, unsuitability for pigment printing fabrics, waste and the like, and achieves the effect of simple preparation and use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An agent for improving the dry rubbing fastness of pigment printed fabrics, comprising the following components by weight percentage: 50.0% of polyether-modified polydimethylsiloxane, 5.0% of blocked water-based polyurethane crosslinking agent, polyacrylate Thickener 1.0%, deionized water 44.0%;

[0022] Accurately weigh each component according to the above weight percentage, stir evenly, and prepare a dry rubbing fastness improving agent for pigment printed fabric, with a viscosity of 23400 mPa·s.

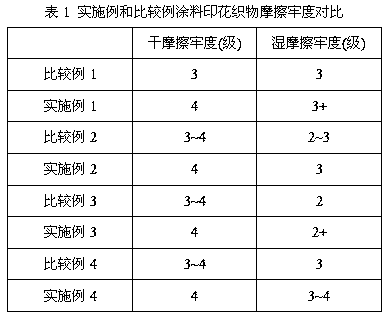

[0023] According to the formula of 5% paint red, 20% binder, 1.5% dry rubbing fastness enhancer of pigment printing fabric, and 3% thickener, the pigment printing paste is prepared, the viscosity is 25300 mPa s, and it is printed by rotary screen printing process Put it on pure cotton 40*40 fabric, dry it with hot air at 120°C, and then bake it at 160°C for 1.5 minutes to test its rubbing fastness, see Table 1.

Embodiment 2

[0027] An agent for improving the dry rubbing fastness of pigment printed fabrics, comprising the following components by weight percentage: 70.0% of hydroxyl-terminated polydimethylsiloxane, 7.0% of blocked water-based polyurethane crosslinking agent, polyacrylate extender Thickener 1.0%, deionized water 22.0%;

[0028] Accurately weigh each component according to the above weight percentage, stir evenly, and prepare a dry rubbing fastness improving agent for pigment printed fabric, with a viscosity of 25600 mPa·s.

[0029] According to the formula of 5% paint blue, 30% adhesive, 1.5% dry rubbing fastness enhancer of pigment printing fabric, and 3% thickener, the pigment printing paste is prepared, the viscosity is 26800 mPa s, and it is printed by rotary screen printing process Put it on pure cotton 40*40 fabric, dry it with hot air at 120°C, and then bake it at 160°C for 1.5 minutes to test its rubbing fastness, see Table 1.

Embodiment 3

[0033] An agent for improving the dry rubbing fastness of pigment printed fabrics, comprising the following components by weight percentage: 50.0% of polyether modified polyethylene wax emulsion, 5.0% of blocked water-based polyurethane crosslinking agent, and 1.5% of polyurethane thickener %, deionized water 45.0%;

[0034] Accurately weigh each component according to the above weight percentage, stir evenly, and prepare a dry rubbing fastness improving agent for pigment printing fabric, with a viscosity of 27200mPa·s.

[0035] According to the formula of 5% paint black, 25% binder, 1.0% pigment printing fabric dry rubbing fastness improving agent, 3% thickener, the pigment printing paste is prepared, the viscosity is 25700 mPa s, and it is printed by flat screen printing process Put it on pure cotton 15*15 fabric, dry it with hot air at 120°C, and then bake it at 160°C for 1.5 minutes to test its rubbing fastness, see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com