Method for manufacturing artificial board with crop stalk and wood mixing

A technology of crop stalks and wood-based panels, which is applied in the direction of manufacturing tools, wood processing appliances, and pretreatment of molding materials, etc. It can solve problems such as difficulty in obtaining satisfactory bonding strength, affecting product physical properties, and low fiber acquisition rate, and achieves improvement. strength, solve the shortage of wood resources, and reduce the effect of formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

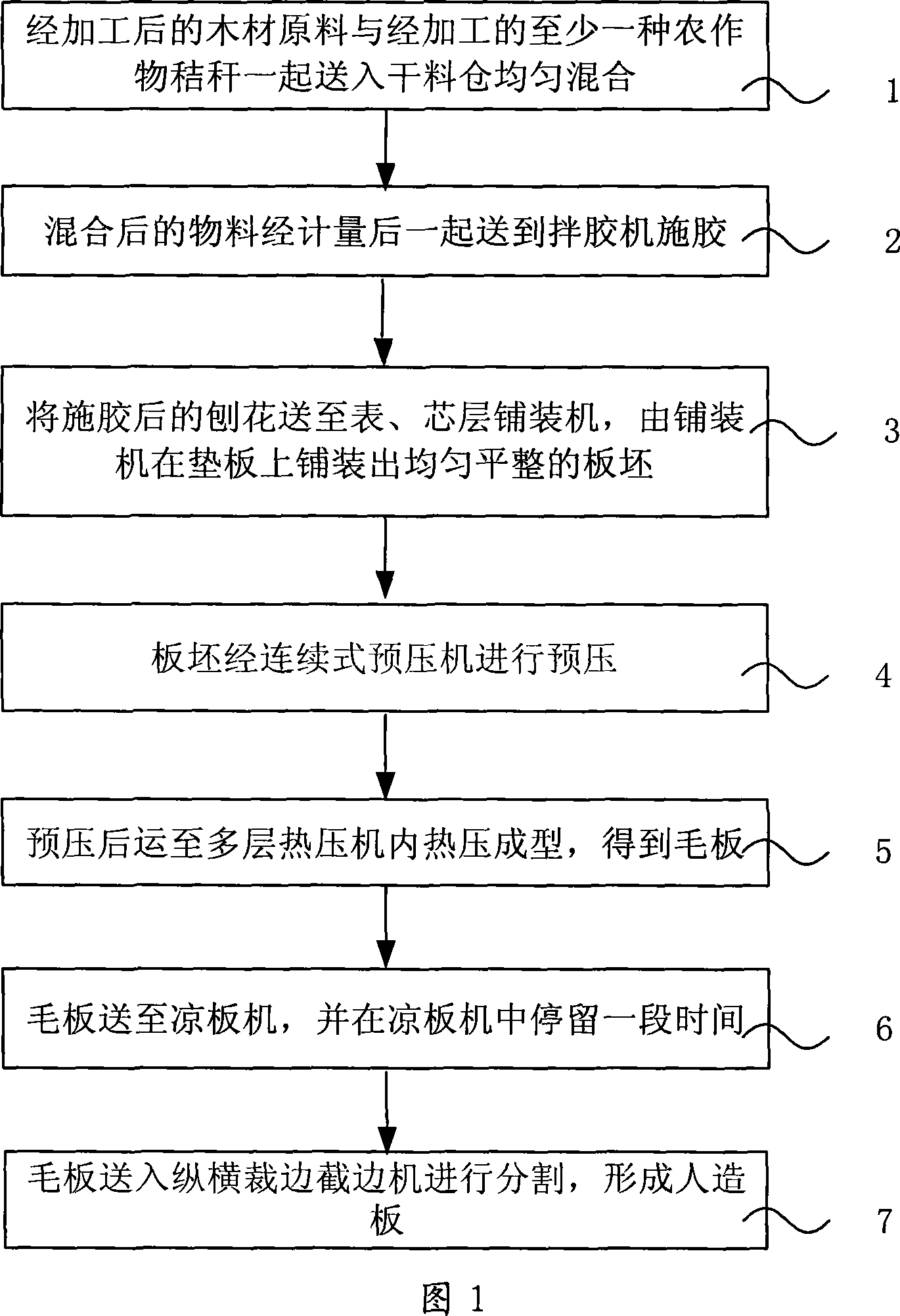

[0025] Fig. 1 is the flow chart of the present invention utilizes crop stalks and timber to mix and manufacture artificial panel method, as shown in Fig. 1, this method comprises:

[0026] Step 1: The processed wood raw material and at least one processed crop straw are sent to the dry silo for uniform mixing;

[0027] Step 2: After the mixed materials are measured, they are sent to the glue mixer for sizing together;

[0028] Step 3: Send the shavings after sizing to the surface and core layer paving machine, and the paving machine will pave a uniform and flat slab on the backing plate;

[0029] Step 4: The slab is pre-pressed by a continuous pre-pressing machine;

[0030] Step 5: After pre-pressing, it is transported to a multi-layer hot press for hot-pressing to obtain a raw board;

[0031] Step 6: Send the raw board to the cooling machine and stay in the cooling machine for a period of time;

[0032] Step 7: The raw board is sent to the vertical and horizontal cutting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com