Process for producing hexamethylol melamine

A technology of hexamethylol melamine and methylol melamine, which is applied in the field of production and preparation of hexamethylol melamine, can solve the problems of low formaldehyde content and difficulty in the treatment of formaldehyde wastewater, achieve low formaldehyde content, save transportation costs, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

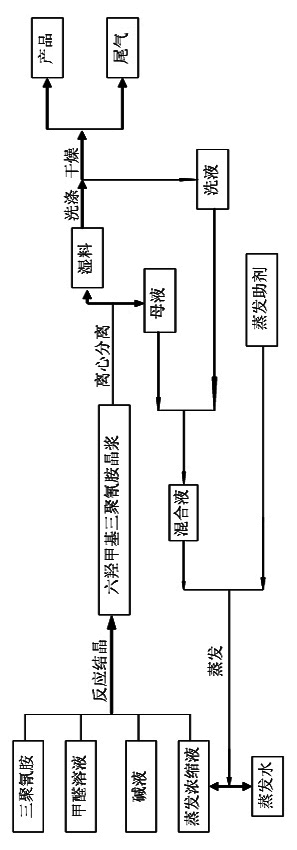

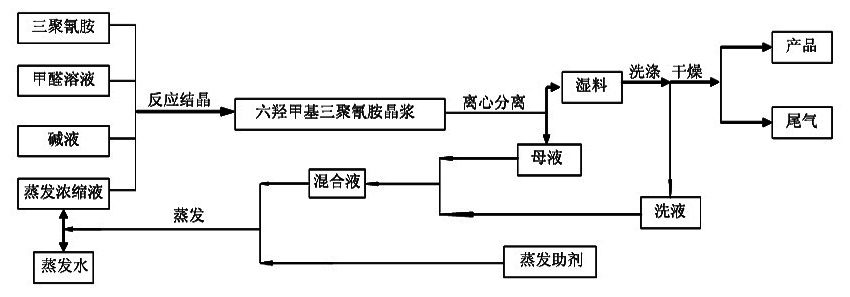

Image

Examples

Embodiment 1

[0051] Formaldehyde process:

[0052] For the preparation method of formaldehyde in this embodiment, be iron-molybdenum method formaldehyde process. The raw material methanol is metered and enters the methanol evaporator for gasification, and then mixes with air mixed gas and steam, and the mixed gas undergoes oxidative dehydrogenation under the action of the high temperature (250-400°C) of the heating element in the oxidation chamber and the iron-molybdenum oxide catalyst reaction. After the reaction gas is cooled, it enters the absorption tower and is circulated and absorbed by desalinated water, and part of the circulating liquid is extracted to obtain a formaldehyde solution (concentration: 50% (wt)).

[0053] Mixing process:

[0054] Send 1.39 t / h of formaldehyde solution with a concentration of 50% (wt), 0.01 t / h of NaOH solution with a concentration of 10% (wt), and 3.856 t / h of evaporating liquid into a static mixer for uniform mixing, and adjust the pH value of the ...

Embodiment 2

[0064] Reaction crystallization process:

[0065] Pump the suspension slurry into the tubular reactor and heat it to 60°C. The melamine and formaldehyde start to react to form hexamethylol melamine. After reacting for 1 hour, it was sent to a crystallizer, and was controlled to stay at 60°C for 4 hours to form a hexamethylolmelamine crystal slurry with a solid content of 20% (wt).

[0066] All the other procedures are with embodiment 1.

Embodiment 3

[0068] Mixing process:

[0069] Formaldehyde solution with concentration of 50% (wt) 1.45t / h, concentration of 20% (wt) Na 2 CO 3 0.015t / h of liquid and 3.856t / h of evaporated liquid are sent to the static mixer for uniform mixing, and the pH value is 8-9. The solution coming out from the static mixer and the melamine 0.475t / h continuously delivered after being weighed by the spiral weighing device are mixed under stirring to form a uniform suspension slurry. All the other procedures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com