Denim-apparel fold finishing agent and fold finishing method

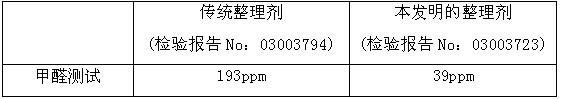

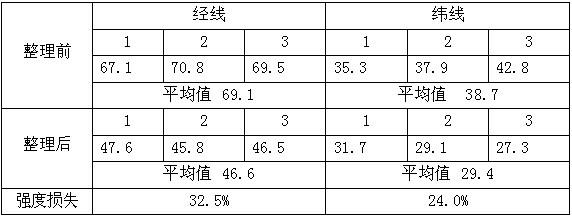

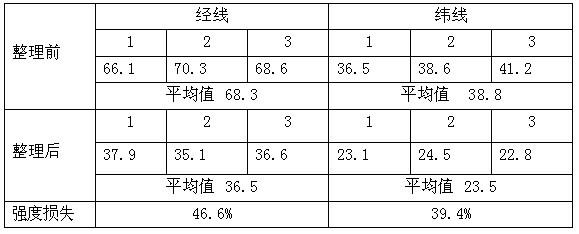

A finishing agent and garment technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of high formaldehyde content of finishing agents, affecting human health and surrounding environment, etc. Effect of Tension Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A wrinkle finishing agent for denim garments, the content in weight percent is: 30% of etherified 2D resin; 4% of magnesium chloride; 5% of modified polyvinyl alcohol; 8% of cationic resin; and 53% of deionized water.

[0035] A method for finishing the folds of denim garments, the steps comprising:

[0036] A. Prepare a finishing solution, the weight percentage of the finishing solution is 15% of the wrinkle finishing agent for denim garments and 85% of deionized water. The weight percentage of the wrinkle finishing agent for denim garments is: 30% etherified 2D resin; 4% catalyst; 5% modified polyvinyl alcohol; 8% cationic resin; 53% deionized water.

[0037] B. Soak denim garments in the finishing solution, pick up and dehydrate after 15 minutes, dehydrate until the squeeze rate is 40%, and dry to 50% dry.

[0038] The liquid squeeze rate is the ratio of the weight of the liquid carried by the denim garment to the weight of the denim garment itself. For example, 100...

Embodiment 2

[0051] A wrinkle finishing agent for denim garments, the weight percent content is: 35% of etherified 2D resin; 5% of aluminum chloride; 10% of modified polyvinyl alcohol; 10% of cationic resin; 40% of deionized water.

[0052] A method for finishing the folds of denim garments, the steps comprising:

[0053] A. Prepare a finishing solution, the weight percentage of the finishing solution is 20% of the wrinkle finishing agent for denim garments and 80% of deionized water.

[0054] The wrinkle finishing agent for denim garments contains: 35% etherified 2D resin; 5% catalyst; 10% modified polyvinyl alcohol; 10% cationic resin; 40% deionized water.

[0055] B. Spray the finishing liquid onto the denim garment, spray until the squeeze rate is 40-50%, and then dry to 5-6% dry.

[0056] C. Put the denim garment on the model, and manually fold it into the required wrinkle shape according to the requirements of the trousers.

[0057] D. Put the denim garment in a dryer and dry it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com