Environment-friendly vehicle natural fiber composite material and preparation method as well as application thereof

A natural fiber and composite material technology, applied in chemical instruments and methods, cellulose plastic material layered products, vehicle parts, etc., can solve the problems of difficult degradation of waste, limited material resources, natural environment pollution, etc., and achieve water content Low change rate, low formaldehyde content, and the effect of improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

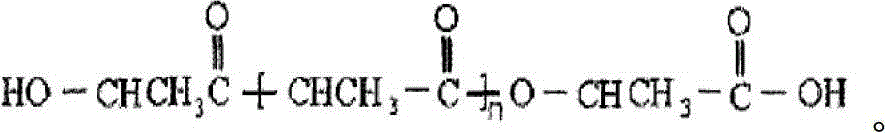

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Automotive interior

[0026] Immerse the continuous sisal fiber fabric with a water content of 0.2% in an ethanol solution of silane coupling agent KH550 with a mass fraction of 2% for 2 minutes;

[0027] The treated continuous sisal fiber fabric is pulled by a tractor and continuously fed into the mixed slurry, which contains a flame retardant (tris(1-oxo-1-phospha-2,6,7-trioxy Heterobicyclo[2,2,2]octane-4-methylene) phosphate), antibacterial agent (2,4,4-trichloro-2'-hydroxy-diphenyl ether), antioxidant (four { β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid} pentaerythritol), anti-ultraviolet agent (bis(2,2,6,6-tetramethylpiperidinyl) sebacate) , the mass ratio is 2:0.2:0.1:0.1, and the immersion treatment is 60s.

[0028] The treated continuous natural fiber fabric was dried until its water content was 0.2%, then pulled through molten polylactic acid, dipped for 5 seconds, and then directly hot-pressed at a temperature of 170°C for 2 seconds to obtain...

Embodiment 2

[0030] Example 2 Automotive interior

[0031] The jute fiber fabric is dried to its water content and is 0.15%, is immersed in the acetone solution of the silane coupling agent KH570 of mass fraction 7% then, handles 10min;

[0032] The treated continuous natural fiber fabric is pulled by a tractor and continuously fed into the mixed slurry, which contains a flame retardant (1-oxo-4-hydroxymethyl-2,6,7-trioxa-1- Phosphabicyclo[2,2,2]octane), antibacterial agent (3-(dimethoxysilyl)propyldimethyloctadecylammonium chloride), antioxidant ((3,5- Ditert-butyl-4-hydroxyphenyl) octadecyl propionate), anti-ultraviolet agent (bis (2,2,6,6-tetramethylpiperidinyl) sebacate), the mass ratio is 3 :0.2:0.1:0.1, immersion treatment for 180s.

[0033] The treated continuous natural fiber fabric was dried until its moisture content was 0.15%, then pulled and impregnated with molten polylactic acid for 2 seconds, and then directly hot-pressed at a temperature of 180°C for 2 seconds to obtain a...

Embodiment 3

[0035] Example 3 Automobile Exterior

[0036] Dry the ramie fiber fabric until its water content is 0.1%, and then immerse it in the acetone solution of silane coupling agent KH560 with a mass fraction of 5%, and treat it for 5 minutes;

[0037] The treated continuous natural fiber fabric is pulled by a tractor and continuously fed into the mixed slurry, which contains flame retardant (ammonium sulfate), antibacterial agent (polyoxyalkylene trialkylammonium salt), antioxidant (dilauryl thiodipropionate), anti-ultraviolet agent (bis(2,2,6,6-tetramethylpiperidinyl) sebacate), the mass ratio is 2.5:0.2:0.1:0.1, Submerged for 60s.

[0038] The treated continuous natural fiber fabric is dried until its water content is 0.1%, and then drawn through molten polylactic acid, dipped for 5 seconds and then directly hot-pressed at a temperature of 190°C for 2 seconds to obtain a natural fiber polylactic acid composite felt.

[0039] Cut the natural fiber polylactic acid composite felt i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com