Self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and preparation method thereof

An ABS material and self-cleaning technology, applied in the field of polymer materials, can solve the problems of endangering human health, reducing the level of emission, and increasing the emission, and achieve the effects of eliminating hazards, reducing emission, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

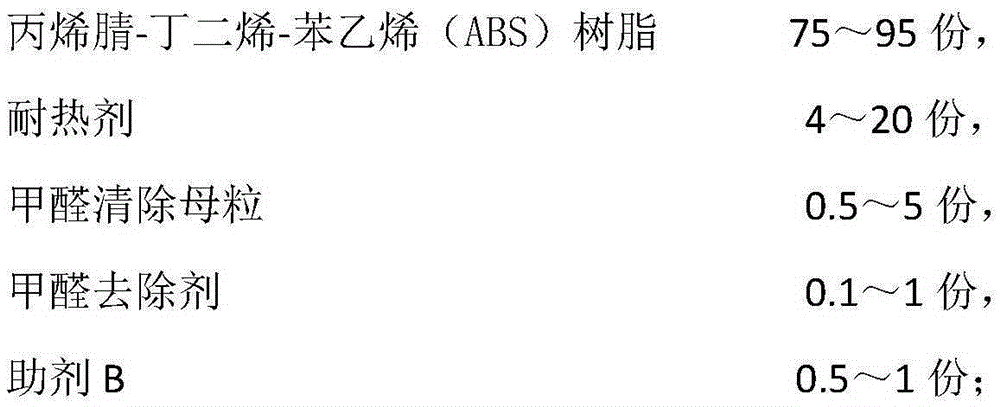

Method used

Image

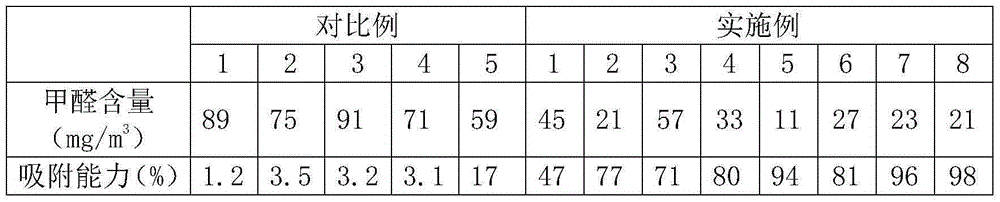

Examples

Embodiment 1

[0052] (1) Weigh the components of each masterbatch by weight: diatomaceous earth (5000 mesh) is 90Kg, 2-imidazolidinone is 10Kg, and other additives are 1Kg (Among them, antioxidant 1010 is 0.25Kg, antioxidant 168 is 0.25Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg);

[0053] (2) Place the prepared masterbatch components in a medium-speed mixer and mix for 20 minutes to obtain a mixture;

[0054] (3) Place the mixture in an internal mixer, control the temperature at 200° C., rotate speed at 20 rpm, and blend for 5 minutes, then granulate to obtain formaldehyde scavenging masterbatch.

[0055] (4) Weigh each component by weight: ABS8391 is 80Kg, KR2556 is 15Kg, and other additives are 1Kg (Among them, antioxidant 1010 is 0.25Kg, antioxidant 168 is 0.25Kg, lubricant PETS (pentaerythritol stearin) Ester) is 0.5Kg);

[0056] (5) Place the prepared product components in a medium-speed mixer and mix for 20 minutes to obtain a mixture;

[0057] (6) Put the mixture into a twin-scre...

Embodiment 2

[0059] (1) Weigh the components of each masterbatch by weight: diatomaceous earth (5000 mesh) is 90Kg, 2-imidazolidinone is 10Kg, and other additives are 1Kg (Among them, antioxidant 1010 is 0.25Kg, antioxidant 168 is 0.25Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg);

[0060] (2) Place the prepared masterbatch components in a medium-speed mixer and mix for 20 minutes to obtain a mixture;

[0061] (3) Place the mixture in an internal mixer, control the temperature at 200° C., rotate speed at 20 rpm, and blend for 5 minutes, then granulate to obtain formaldehyde scavenging masterbatch.

[0062] (4) Weigh each component by weight: ABS8391 is 80Kg, KR2556 is 15Kg, and other additives are 1Kg (Among them, antioxidant 1010 is 0.25Kg, antioxidant 168 is 0.25Kg, lubricant PETS (pentaerythritol stearin) Ester) is 0.5Kg);

[0063] (5) Place the prepared product components in a medium-speed mixer and mix for 20 minutes to obtain a mixture;

[0064] (6) Put the mixture into a twin-scre...

Embodiment 3

[0066] (1) Weigh each masterbatch component by weight: diatomaceous earth (5000 mesh) is 95Kg, hydrazine carbonate is 5Kg, and other additives are 1Kg (Among them, antioxidant 1010 is 0.25Kg, antioxidant 168 is 0.25 Kg, lubricant PETS (pentaerythritol stearate) is 0.5Kg);

[0067] (2) Place the prepared masterbatch components in a medium-speed mixer and mix for 20 minutes to obtain a mixture;

[0068] (3) Place the mixture in an internal mixer, control the temperature at 200° C., rotate speed at 20 rpm, and blend for 5 minutes, then granulate to obtain formaldehyde scavenging masterbatch.

[0069] (4) Weigh each component by weight: ABS8391 is 81Kg, KR2556 is 15Kg, and other additives are 1Kg (Among them, antioxidant 1010 is 0.25Kg, antioxidant 168 is 0.25Kg, lubricant PETS (pentaerythritol stearin) Ester) is 0.5Kg);

[0070] (5) Place the prepared product components in a medium-speed mixer and mix for 20 minutes to obtain a mixture;

[0071] (6) Put the mixture into a twin-screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com