Completely-biodegradable pre-coating film

A biodegradable, pre-coating technology, applied in layered products, pressure-sensitive films/sheets, film/sheet release coatings, etc., can solve the problem of non-degradable films, and achieve bright gloss, thorough decomposition, and rapid decomposition. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

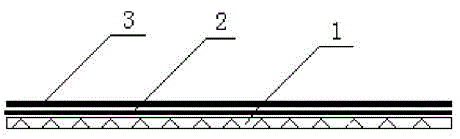

[0033] A fully biodegradable precoat film, comprising a substrate, an intermediate layer and an adhesive adhesive layer, wherein the intermediate layer is located between the base layer and the adhesive adhesive layer,

[0034] The formulation of each material of the base material according to parts by weight is as follows:

[0035] 1 part of polyethylene terephthalate, 5 parts of biaxially oriented polypropylene film, 10 parts of biaxially oriented polyester film, 1 part of biaxially oriented nylon film, 1 part of terpene resin;

[0036] Each material of the intermediate layer is formulated as follows according to parts by weight:

[0037] 1 part of polyethylene wax, 5 parts of elastomer;

[0038] The formula of each material of the adhesive glue layer according to parts by weight is as follows:

[0039] 5 parts of ethylene-vinyl acetate resin, 1 part of hydrogenated petroleum resin, 3 parts of hydrogenated rosin glyceride, 1 part of petroleum resin, and 1 part of water-bas...

Embodiment 2

[0049] A fully biodegradable precoat film, comprising a substrate, an intermediate layer and an adhesive adhesive layer, wherein the intermediate layer is located between the base layer and the adhesive adhesive layer,

[0050] The formulation of each material of the base material according to parts by weight is as follows:

[0051] 5 parts of polyethylene terephthalate, 7 parts of biaxially oriented polypropylene film, 13 parts of biaxially oriented polyester film, 3 parts of biaxially oriented nylon film, 2 parts of terpene resin;

[0052] Each material of the intermediate layer is formulated as follows according to parts by weight:

[0053] 5 parts of polyethylene wax, 10 parts of elastomer;

[0054] The formula of each material of the adhesive glue layer according to parts by weight is as follows:

[0055] 7 parts of ethylene-vinyl acetate resin, 3 parts of hydrogenated petroleum resin, 5 parts of hydrogenated rosin glyceride, 5 parts of petroleum resin, and 5 parts of w...

Embodiment 3

[0065] A fully biodegradable precoat film, comprising a substrate, an intermediate layer and an adhesive adhesive layer, wherein the intermediate layer is located between the base layer and the adhesive adhesive layer,

[0066] The formulation of each material of the base material according to parts by weight is as follows:

[0067] 10 parts of polyethylene terephthalate, 10 parts of biaxially oriented polypropylene film, 15 parts of biaxially oriented polyester film, 5 parts of biaxially oriented nylon film, 4 parts of terpene resin;

[0068] Each material of the intermediate layer is formulated as follows according to parts by weight:

[0069] 10 parts of polyethylene wax, 15 parts of elastomer;

[0070] The formula of each material of the adhesive glue layer according to parts by weight is as follows:

[0071] 10 parts of ethylene-vinyl acetate resin, 5 parts of hydrogenated petroleum resin, 6 parts of hydrogenated rosin glyceride, 10 parts of petroleum resin, and 10 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com