Spinning device for producing bright and clean yarn through spiral airflow

A technology of spiral air flow and smooth yarn, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc. It can solve the irregular direction of the main air flow, reduce the braking effect of the traveler, and interfere with the steel wire Smooth loop sliding and other problems, to achieve the effect of reducing yarn hairiness, bright luster, and delicate fabric feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

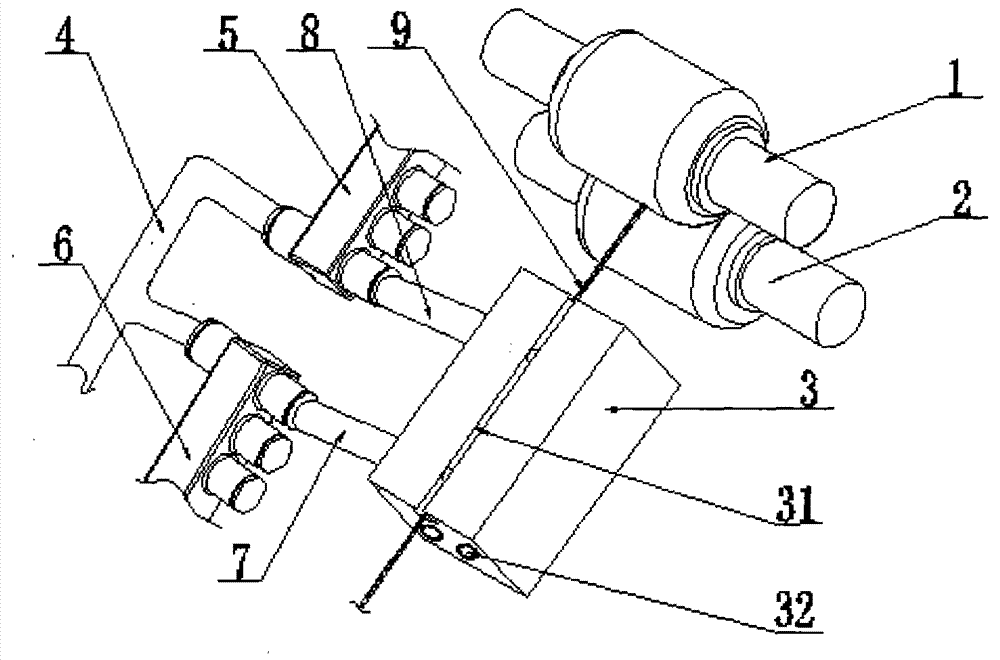

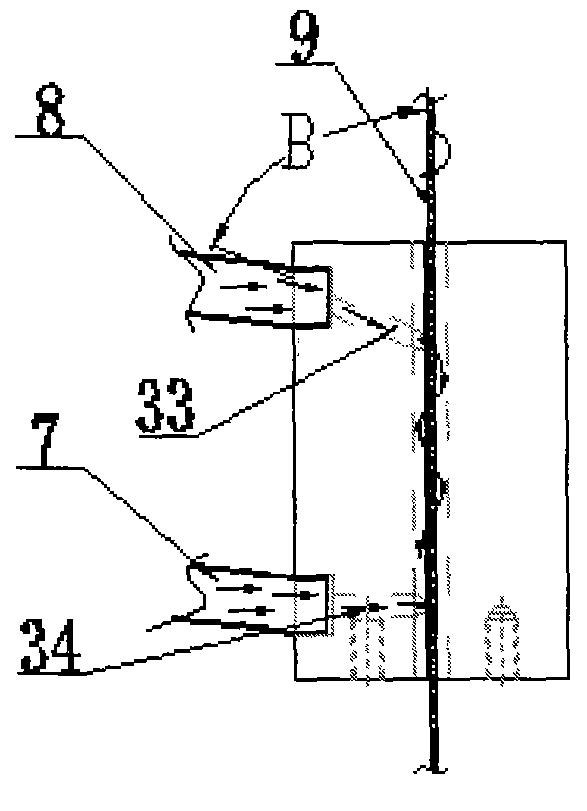

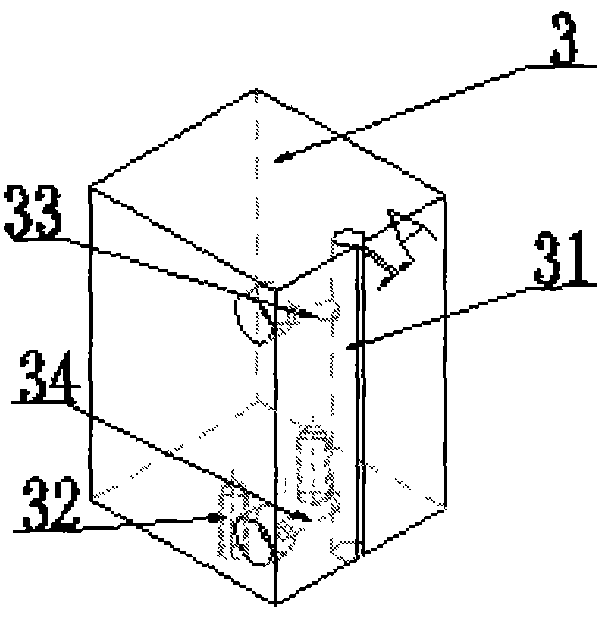

[0017] Referring to the accompanying drawings, a spinning device that utilizes spiral airflow to produce smooth yarn includes an upper twisting wheel 1 and a lower twisting wheel 2, and the upper twisting wheel 1 and the lower twisting wheel 2 pass through the yarn 9. The yarn 9 passes through the wire slot 31 in the spiral airflow generator 3. The wire slot 31 is a circular through hole with a diameter of 4 mm. The opening width of the outer axial direction of the wire slot 31 is 2 mm. There are two holes on the side of the airflow generator 3, which are respectively the upper spiral blow hole 33 and the lower horizontal blow hole 34. The air hole 33 and the horizontal air blow hole 34 are tangent to the inner wall of the wire groove 31, the spiral air blow hole 33 is connected with the external spiral air inlet pipe 8, and the horizontal air blow hole 34 is connected with the external horizontal air inlet pipe 7; On the basis of the line, the processing angle of the spiral a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com