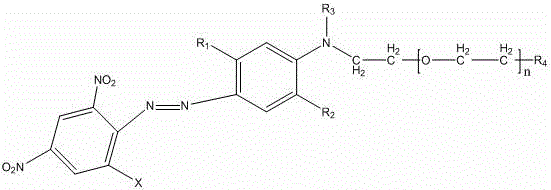

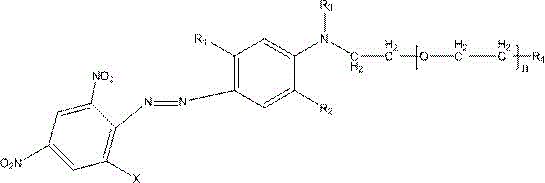

Strong-alkali-resistant moderate-temperature disperse violet dye as well as compound mixture and preparation method thereof

A technology of disperse dyes and disperse violet, applied in azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of high pollution of dyeing waste liquid, non-compliance with energy saving and emission reduction, high cost, and reduce energy consumption and pollution. , The effect of excellent fastness and high improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 44g of concentrated sulfuric acid with a mass concentration of 90-98% in the reaction three-necked flask, add 17g of 2-bromo-4,6-dinitroaniline under stirring, maintain the temperature at 45-50°C, and keep it warm for 1.0 hours to make 2-bromo-4, Dissolve all 6-dinitroaniline until clear; add ice to cool down to 24°C, start to drop 21.5g of nitrosylsulfuric acid, and use ice to ensure that the temperature of the material in the reactor is maintained at 15-20°C during the dropwise addition; use 1.5- After adding nitrosyl sulfuric acid in 2.0 hours, keep warm for another 3 hours, and the temperature is still controlled at 15-20°C; before the end of the diazonium reaction, do an end point test; after the test is passed, it will be a diazonium solution, ready to discharge.

[0023] While waiting for the diazo insulation reaction, use a 1000mL three-necked bottle for coupling, and prepare emulsifier OP-10 into a solution with a mass concentration of 10% for later use. Ad...

Embodiment 2

[0026] Add 40g of concentrated sulfuric acid with a mass concentration of 90-98% to the reaction three-necked flask, add 10g of 2-chloro-4,6-dinitroaniline under stirring, maintain the temperature at 45-50°C, and keep it warm for 1.0 hours to make 2-chloro-4, 6-Dinitroaniline was completely dissolved until clear. Add ice to cool down to 24°C, start to add 20 g of nitrosyl sulfuric acid dropwise, and use ice to ensure that the temperature of the material in the reactor is maintained at 10-15°C during the dropwise addition. It takes 1.5-2.0 hours to finish adding nitrosyl sulfuric acid, and then keep it warm for 5 hours, and the temperature is still controlled at 10-15°C. Before the end of the diazonium reaction, do the end point detection. After passing the test, it is diazo liquid, ready to discharge.

[0027] While waiting for the diazo insulation reaction, use a 1000mL three-necked bottle for coupling, and prepare emulsifier OP-10 into a solution with a mass concentration ...

Embodiment 3

[0030] Add 50g of concentrated sulfuric acid with a mass concentration of 90-98% in the reaction three-necked flask, add 18g of 2-bromo-4,6-dinitroaniline under stirring, maintain the temperature at 45-50°C, and keep it warm for 1.0 hours to make 2-bromo-4, 6-Dinitroaniline was completely dissolved until clear. Add ice to cool down to 24°C, and start to add 25 g of nitrosylsulfuric acid dropwise. It takes 1.5-2.0 hours to finish adding the nitrosyl sulfuric acid, and then keep the temperature for 4 hours, and the temperature is still controlled at 15-20°C. Before the end of the diazonium reaction, do the end point detection. After passing the test, it is diazo liquid, ready to discharge.

[0031]While waiting for the diazo insulation reaction, use a 1000mL three-necked bottle for coupling, and prepare emulsifier OP-10 into a solution with a mass concentration of 10% for later use. Add 240g of water, 10g of emulsifier OP-10 solution with a mass concentration of 10%, and 0.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com