Moisture absorption and perspiration antistatic fabric

A moisture-wicking, anti-static technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor moisture-wicking effect of fabrics, poor anti-static comfort, etc. Leaky, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

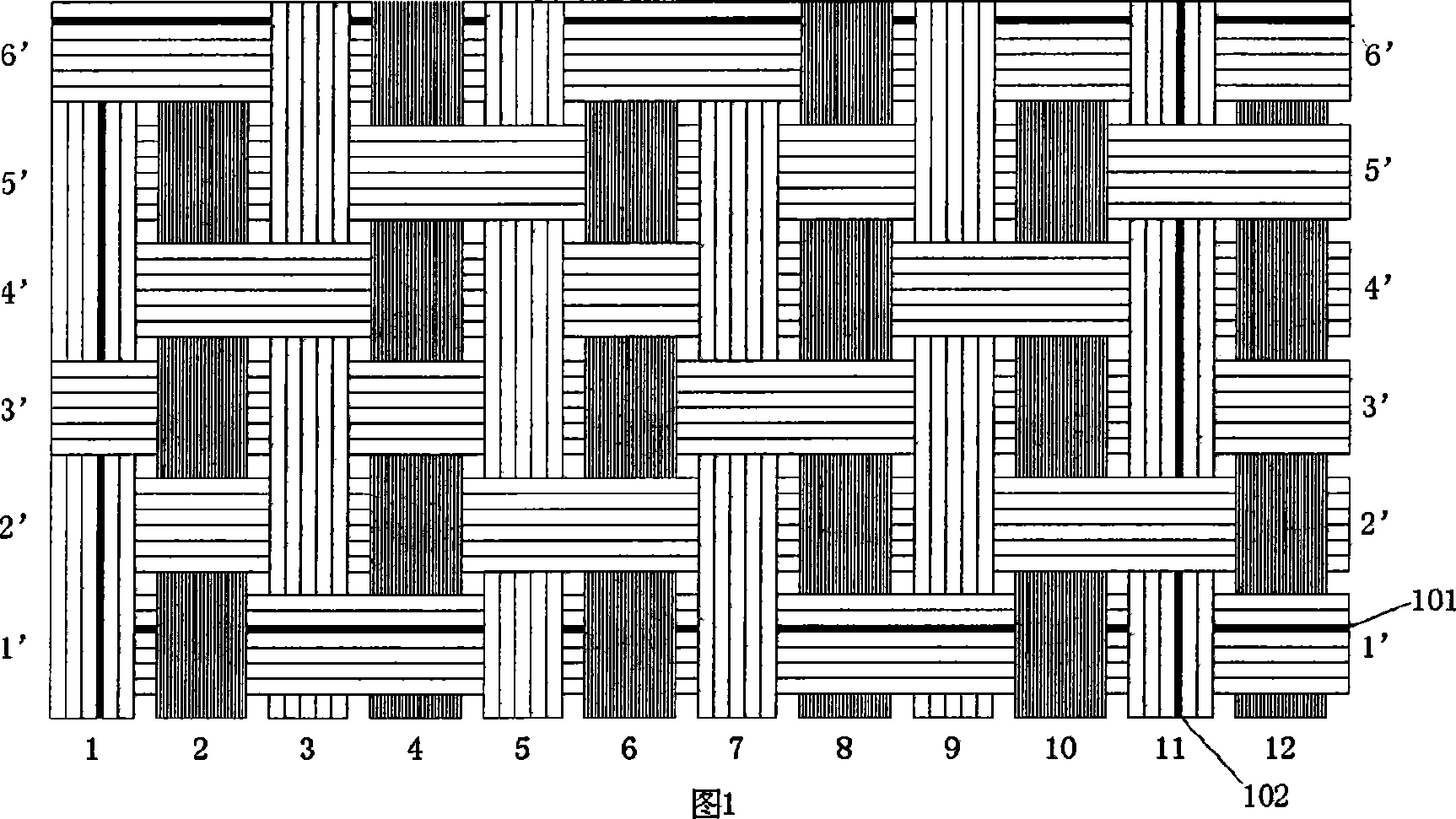

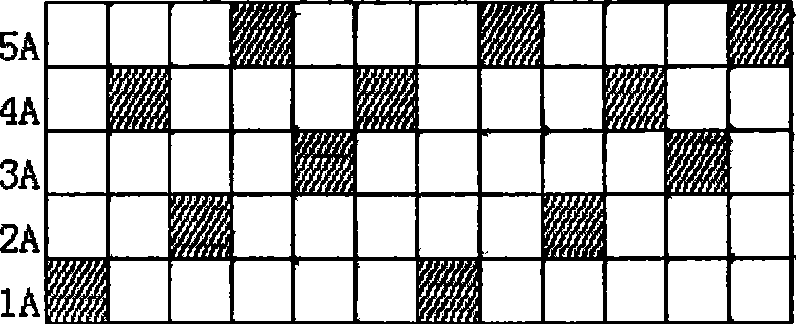

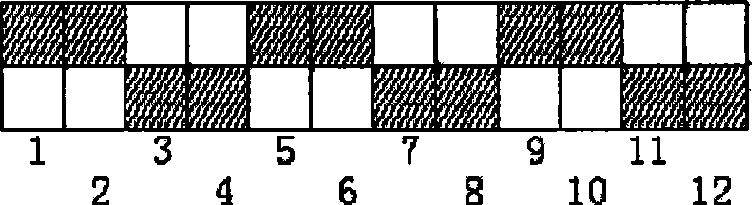

[0022] Shown in Fig. 1, 4 is respectively the local schematic diagram and the tissue diagram of present embodiment weaving, and fabric adopts heavy flat weave, and warp yarn 1,3,5,7,9,11 is inside warp among the figure, and weft yarn 1 ', 2 ', 3', 4', 5', 6' constitute the inner weave of the fabric, warp yarns 2, 4, 6, 8, 10, and 12 are surface warps, and weft yarns 1', 2', 3', 4', 5 ', 6' constitute the table organization of the fabric. The inner weave adopts two up and one down right twill weave, and the number of meridians is Sj 里 =1, the arrangement ratio of inner and outer warps is 1:1, and the number of tissue cycles R 里 = 3, the number of looped warp yarns in the organization Rj 里 And the number of loop weft yarns in the organization Rw 里 Both are 3; the table weave adopts one up and one down plain weave, and the number of weave cycles is R 表 , warp cycle number Rj 表 and weft cycle number Rw 表 All are 2, therefore, the number of warp yarn cycles Rj after heavy fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com