Composite humidity adjusting material

A humidity control material, garnet technology, applied in the field of humidity control materials, can solve the problem that humidity control materials cannot have high moisture absorption capacity at the same time. Promote and apply materials and other issues to achieve the effect of increasing the dehumidification rate, improving the dehumidification performance, increasing the specific surface area and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

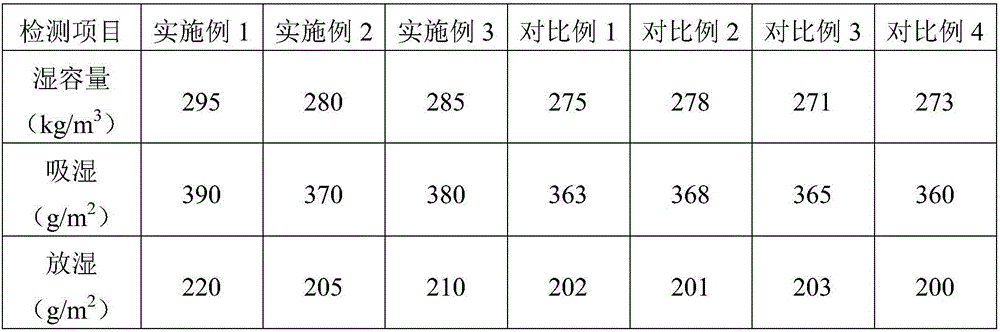

Examples

Embodiment 1

[0018] In the present embodiment, the mesh number of shell powder, xonotlite, garnet, and spinel is 150 mesh; the particle diameter of nano silicon dioxide is 80nm; 3 al 2 (SO 4 ) 3 Garnet porous ceramic material; spinel is magnesium aluminum spinel porous ceramic material prepared by molten salt method.

[0019] A composite humidity-conditioning material, made of the following components in proportions by weight: CaCl 2 ·6H 2 O 8 parts, ZnSO 4 ·7H 2 4 parts of O, 3 parts of shell powder, 2 parts of xonotlite, 4 parts of garnet, 4 parts of spinel, 5 parts of sodium carboxymethyl starch, 6 parts of carboxymethyl cellulose, 6 parts of sodium polyacrylate, shell 6 parts of polysaccharide, 2 parts of sodium lignosulfonate, 2 parts of sodium alginate, 0.5 part of nano silicon dioxide.

Embodiment 2

[0021] In the present embodiment, the mesh number of shell powder, xonotlite, garnet, and spinel is 100 mesh; the particle diameter of nano silicon dioxide is 50nm; 3 al 2 (SO 4 ) 3 Garnet porous ceramic material; spinel is magnesium aluminum spinel porous ceramic material prepared by molten salt method.

[0022] A composite humidity-conditioning material, made of the following components in proportions by weight: CaCl 2 ·6H 2 7 parts of O, ZnSO 4 ·7H 2 3 parts of O, 2 parts of shell powder, 1 part of xonotlite, 3 parts of garnet, 3 parts of spinel, 4 parts of sodium carboxymethyl starch, 4 parts of carboxymethyl cellulose, 5 parts of sodium polyacrylate, shell 4 parts of polysaccharide, 1 part of sodium lignosulfonate, 1 part of sodium alginate, 0.3 part of nano silicon dioxide.

Embodiment 3

[0024] In this embodiment, the mesh number of shell powder, xonotlite, garnet, and spinel is 200 mesh; the particle diameter of nano silicon dioxide is 100nm; 3 al 2 (SO 4 ) 3 Garnet porous ceramic material; spinel is magnesium aluminum spinel porous ceramic material prepared by molten salt method.

[0025] A composite humidity-conditioning material, made of the following components in proportions by weight: CaCl 2 ·6H 2 O 9 parts, ZnSO 4 ·7H 2 5 parts of O, 4 parts of shell powder, 3 parts of xonotlite, 6 parts of garnet, 6 parts of spinel, 6 parts of sodium carboxymethyl starch, 8 parts of carboxymethyl cellulose, 7 parts of sodium polyacrylate, shell 7 parts of polysaccharides, 3 parts of sodium lignosulfonate, 3 parts of sodium alginate, 0.7 parts of nano silicon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com