Processing method making coarse grains and millet boiled and cooked together, and coarse grains obtained by processing

A processing method and technology of miscellaneous grains, applied in the field of miscellaneous grains, can solve the problems of poor pre-ripening, cumbersome processing procedures, and long processing time, and achieve the effects of fast drying time, short soaking time, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

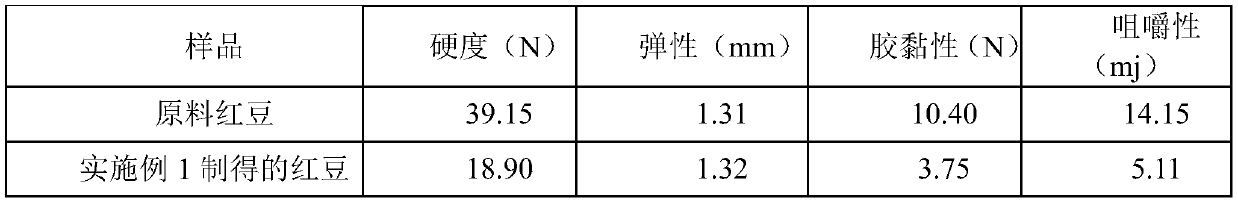

Embodiment 1

[0024] One, red beans are processed according to the processing method of the present invention, and concrete steps are as follows:

[0025] (1) Raw material pretreatment

[0026] Red beans remove gravel, soil clods, insect erosion, mildew, damage and other bad grains, and wash them twice;

[0027] (2) Ultrasonic assisted soaking

[0028] Mix the red beans and water according to the material-to-liquid ratio (mass ratio) of 1:3, and use ultrasonic assisted soaking, the ultrasonic power is 180W, the soaking temperature is 40°C, and the soaking time is 75min. After soaking, drain and set aside;

[0029] (3) Raw material pre-cooking

[0030] Cook the soaked red beans at 115°C and 0.16MPa for 3 minutes, and the red bean particles are intact;

[0031] (4) microwave drying

[0032] The red beans processed in step (3) are dried by microwave, the microwave power is 385W, the drying time is 5min, and the material thickness is 2.4cm. The red beans processed according to the above st...

Embodiment 2

[0050] One, process the barley according to the method of the present invention, concrete steps are as follows:

[0051] (1) Raw material pretreatment

[0052] Barley removes gravel, soil clods, insect-eroded, moldy, damaged and other bad grains, and washes them 3 times;

[0053] (2) Ultrasonic assisted soaking

[0054] Barley is soaked with ultrasonic assistance according to the material-to-liquid ratio (mass ratio) of 1:4. The ultrasonic power is 180W, the soaking temperature is 40°C, and the soaking time is 60 minutes. After soaking, drain and set aside;

[0055] (3) Raw material pre-cooking

[0056] The soaked barley is steamed at 115°C and 0.16Mpa for 3 minutes, and the barley remains intact;

[0057] (4) microwave drying

[0058] The barley obtained in step (3) is dried by microwave, the microwave power is 539W, the drying time is 4min, and the material thickness is 3cm. The seed of Job's tears processed according to the above method can be cooked together with mill...

Embodiment 3

[0071] Embodiment 3 processes black rice according to the method of the present invention

[0072] (1) Raw material pretreatment

[0073] Black rice removes gravel, soil clods, insect-eroded, moldy, damaged and other bad grain rice, and washes it 3 times;

[0074] (2) Ultrasonic assisted soaking

[0075] Black rice is 1: 5 according to material-liquid ratio (mass ratio), adopts ultrasonic assisted soaking, ultrasonic power 300W, soaking temperature 30 ℃, soaking time 10min, after soaking, drain and set aside;

[0076] (3) Raw material pre-cooking

[0077] The black rice after soaking is cooked at 115°C and 0.16Mpa for 2 minutes, and the black rice remains intact;

[0078] (4) microwave drying

[0079] The black rice obtained in step (3) is dried by microwave, the microwave power is 300W, the drying time is 7min, and the material thickness is 4cm. The processed black rice can be cooked together with millet.

[0080] The black rice prepared in Example 3 was boiled in boilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com