Double layer composite melt-blown non-woven fabric

A melt-blown non-woven fabric, oblique diameter technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as user inconvenience, process obstacles, unfavorable production, etc., to improve moisture absorption, fast moisture absorption, reduce surface The effect of specific resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

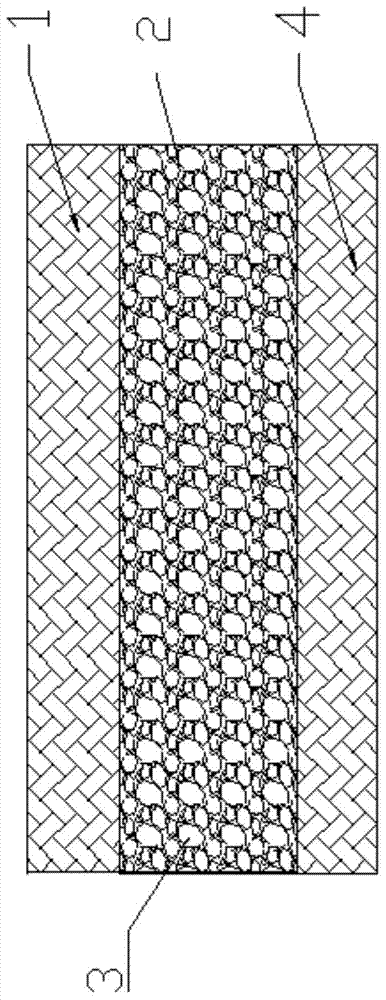

[0014] A two-component composite melt-blown nonwoven fabric includes a first matrix layer 1, a multi-layer oblique jet composite ultrafine short fiber layer 2 and a second matrix layer 4 arranged in sequence from top to bottom.

[0015] Preferably, a water-storage fiber matrix layer 3 is also compounded in the multi-layer oblique-diameter jetted intersecting superfine short fiber layer.

[0016] Preferably, the water-storage fiber matrix layer 3 is interlaced with the multi-layer inclined-diameter injection composite ultrafine short fiber layer to form a whole.

[0017] The two-component composite melt-blown nonwoven fabric is made of short fibers or filaments formed by modifying polypropylene materials for directional spinning or irregular melt-blown struts to form a multi-layer oblique jet composite ultra-fine short fiber layer and storage. The composite fiber network structure composed of water fiber matrix layer, and then the two matrix layers are reinforced by mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com