Method for processing wool and polyester blended fabric with rapid high-efficient moisture absorbable and breathable function

A technology for moisture absorption and perspiration, blended fabrics, applied in textiles and papermaking, fiber processing, physical processing and other directions, can solve problems such as unreachable, degradation of wool water absorption speed, and achieve fast moisture absorption, good irradiation results, and water saving. The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

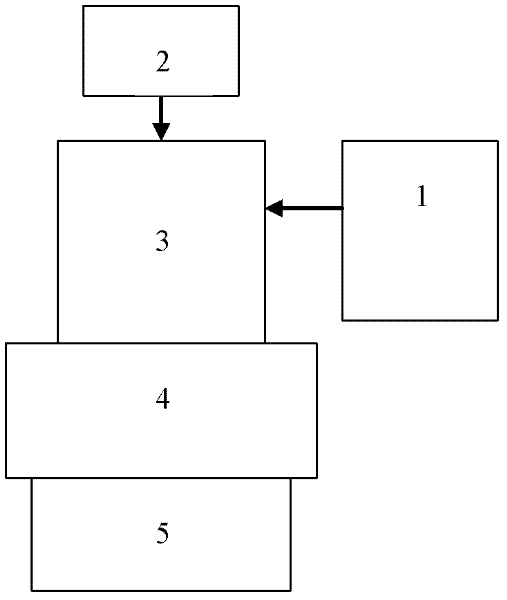

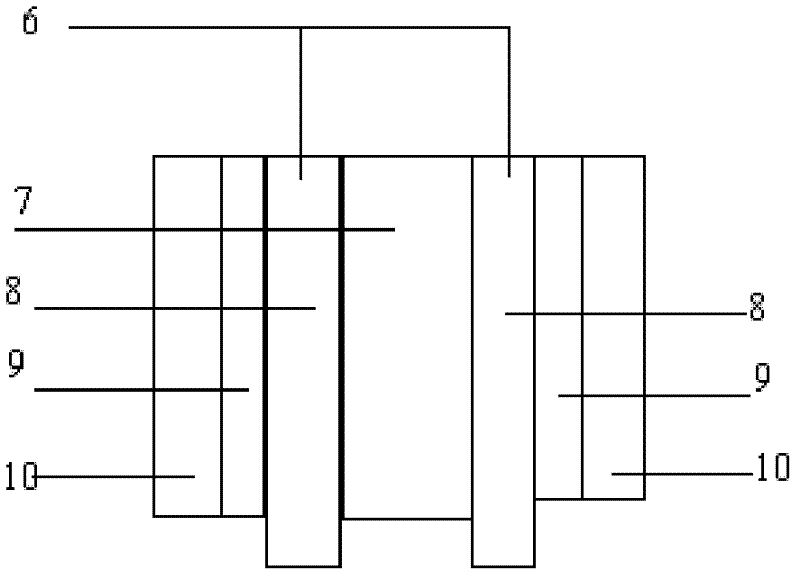

[0011] Such as figure 1 , figure 2 As shown, the present invention carries out radiation mutagenesis through a low-temperature plasma spray gun device under normal pressure to the wool polyester blended fabric, and after the irradiation, alkylsulfonate, alkylphosphate or quaternary ammonium salt are grafted onto the The surface of the fabric can stabilize and enhance the hydrophilicity. The low-temperature plasma spray gun device described therein comprises a grounding device 10, a quartz tube 8 is arranged in the middle of the grounding device 10, a plasma region 9 is formed between the quartz tube 8 and the grounding device 10, and a high-voltage electrode 7 is housed in the quartz tube 8. The upper end of the quartz tube 8 is connected with the air intake system 6 .

[0012] 1) The hydrophilicity of wool has been improved by using argon alone, and the hydrophilicity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com