Anti-mildew drying agent and preparation method thereof

A desiccant and anti-mildew technology, applied in the directions of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems of not easy evaporation, easy to produce mildew, etc., to improve the ability of dehumidification and water retention. , The effect of controlling environmental humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

[0026] An embodiment provided by the invention: 1. A mildew-proof desiccant, the raw materials in the desiccant include anhydrous calcium chloride, molecular sieve, natural plant fiber, activated carbon, isothiazolone, camphor tree extract and citrus extract thing;

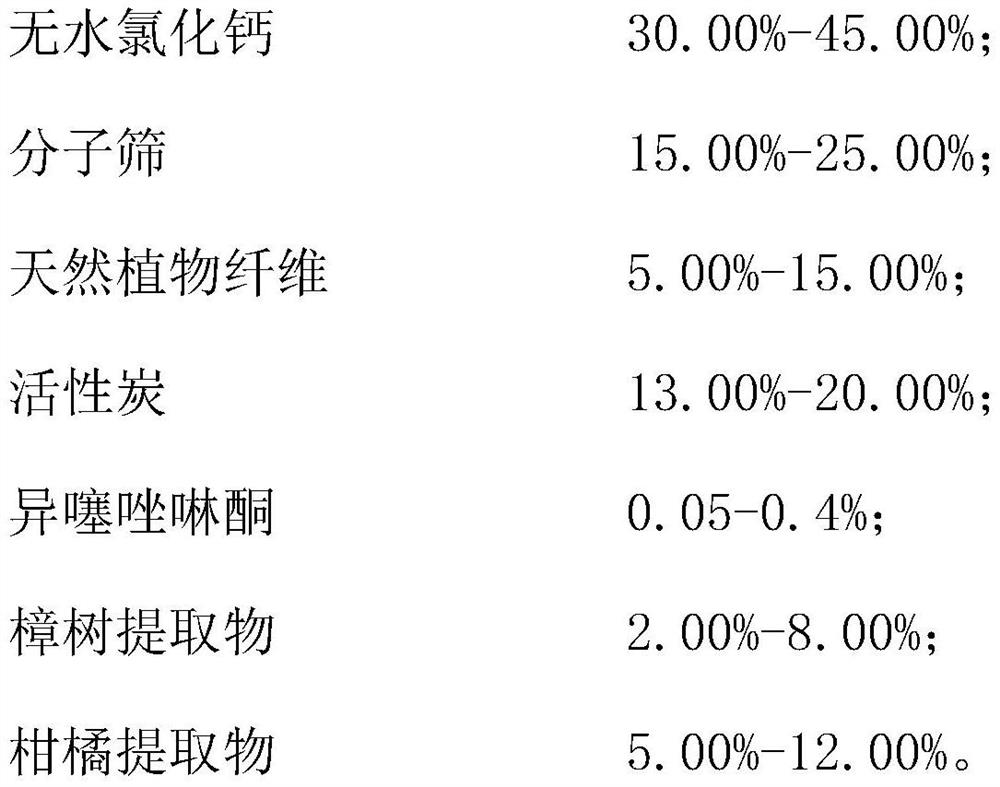

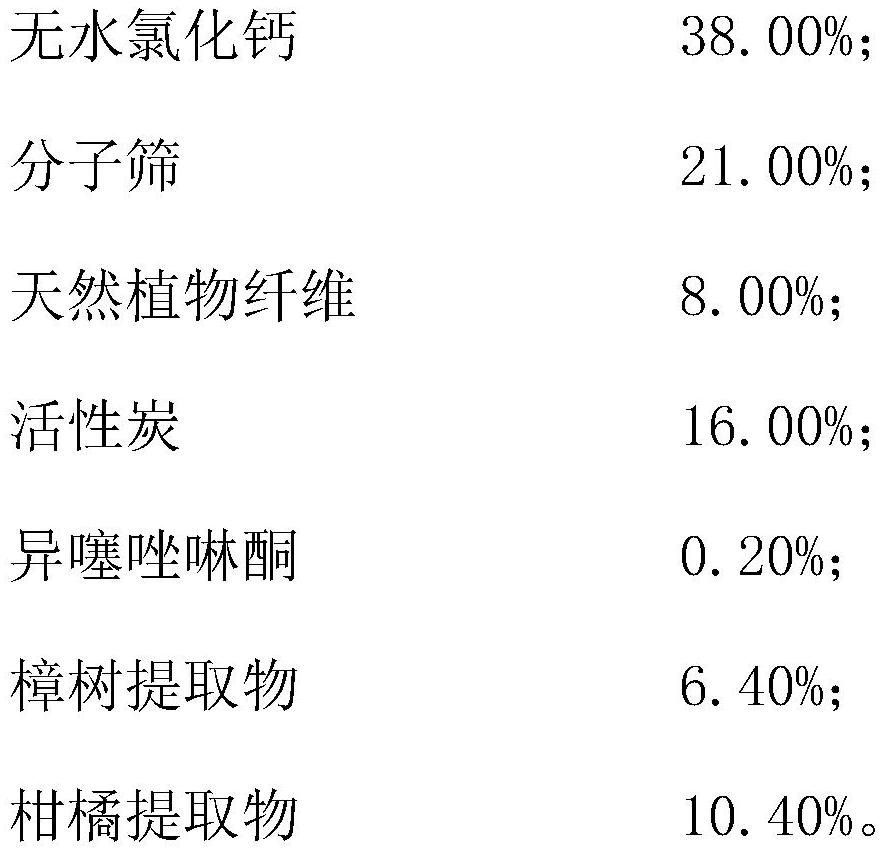

[0027] Wherein, the raw material in the desiccant comprises by weight percent composition:

[0028]

[0029] The moisture absorption rate of calcium chloride desiccant can reach 300%, and the moisture absorption rate is 8-15 times that of ordinary desiccants. After completely absorbing moisture, it will not evaporate, thereby improving the water retention capacity of the desiccant, and ensuring that the water will not evaporate due to the increase in temperature after abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com