Tobacco stem processing method using stem sheets for feeding

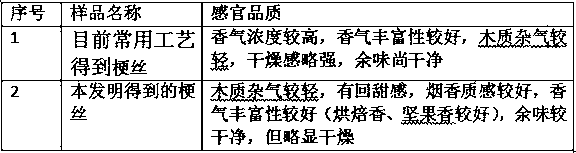

A processing method and technology for tobacco stems, which are applied in the fields of reducing energy consumption and improving the quality of cut stems, can solve the problems of ineffective use of sugar material functions, unfavorable absorption of sugar material by cut stems, and increased sewage treatment load, etc. Conducive to natural alcoholization, good alcoholization effect and fast moisture absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

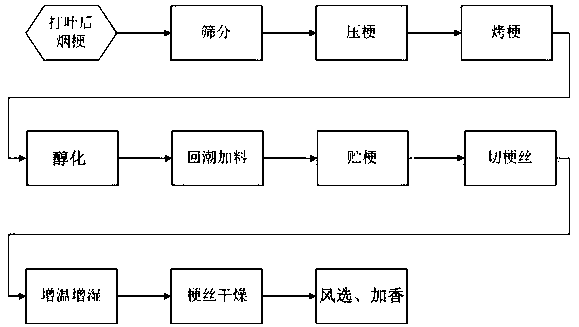

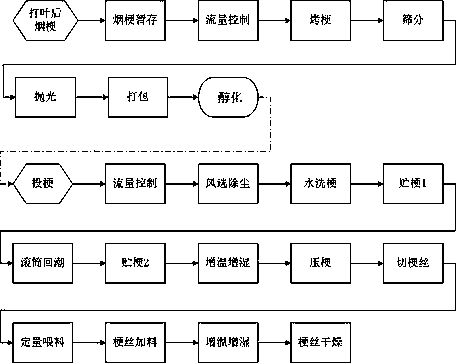

Method used

Image

Examples

Embodiment 1

[0031] The tobacco stems separated from flue-cured tobacco leaves are sieved with a sieve to remove stem heads, stem pieces, stem fragments and small stems, and the moisture content of the tobacco stems is 15-17%.

[0032] Roll the sieved tobacco stems with a stem press machine, and the flow control of the stem press process is 3000kg / h.

[0033] Adjust the pressing gap of the stem pressing machine to 0.7mm, and send the pressed tobacco stems to the roasting machine for drying. As an optimal technical solution, the roasting temperature of the roasting machine is 95°C. After roasting, the moisture content of the tobacco stems It is 11~12%. The dried tobacco stems are sent to the tobacco stem warehouse for alcoholization for 3-12 months.

[0034] Take out the alcoholized tobacco stems from the tobacco stem warehouse, feed them quantitatively into the drum-type moisture regain feeding machine, add 3% (flavored sugar material accounts for 100% of the mass of the tobacco stems) fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com