Tobacco low-temperature drying treatment technology

A technology for drying and processing tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., which can solve the problems of affecting the alcoholization effect of tobacco leaves, loss of activity, and large loss, and achieve microbial and enzyme activity retention, quality improvement, and less material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

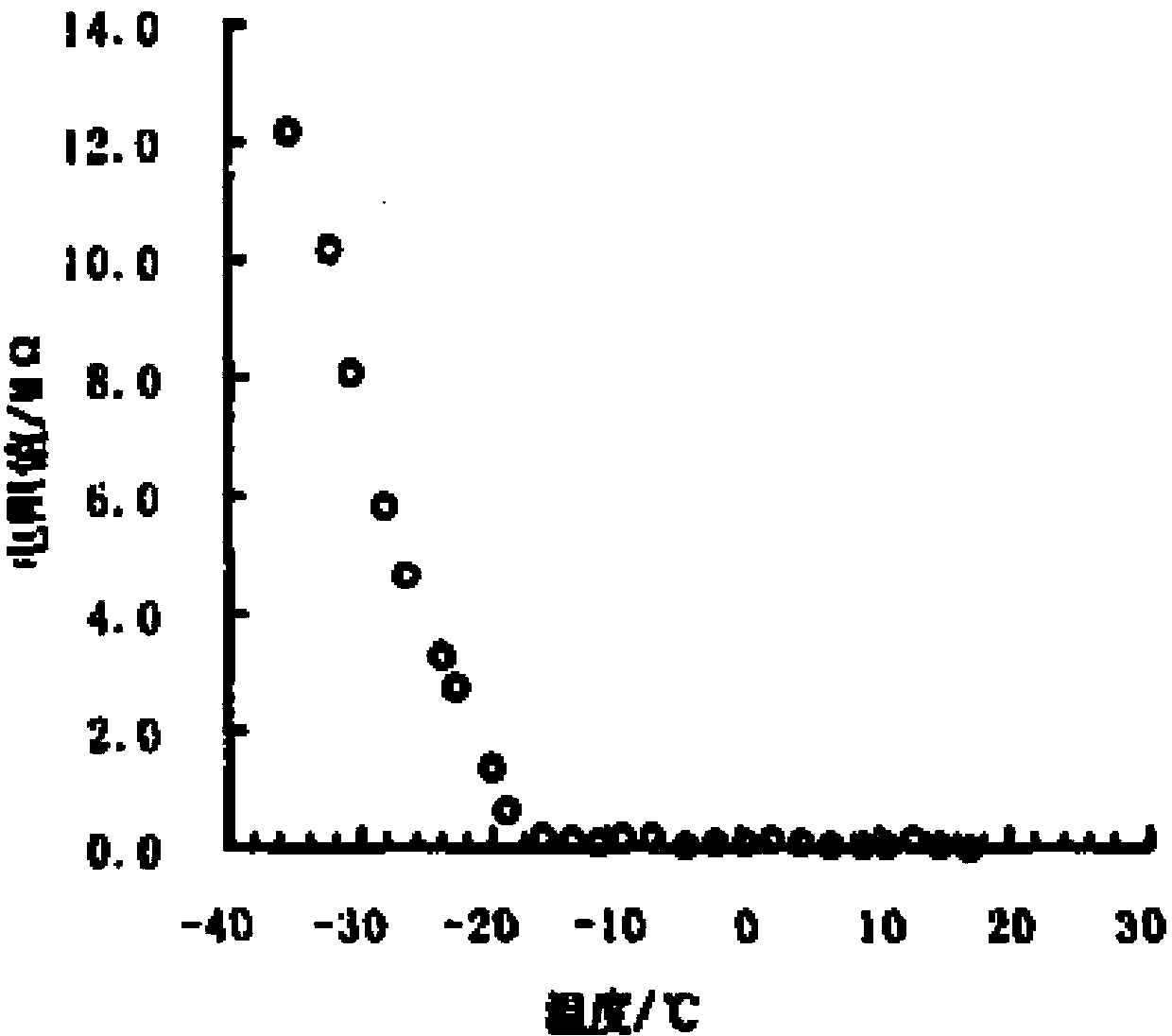

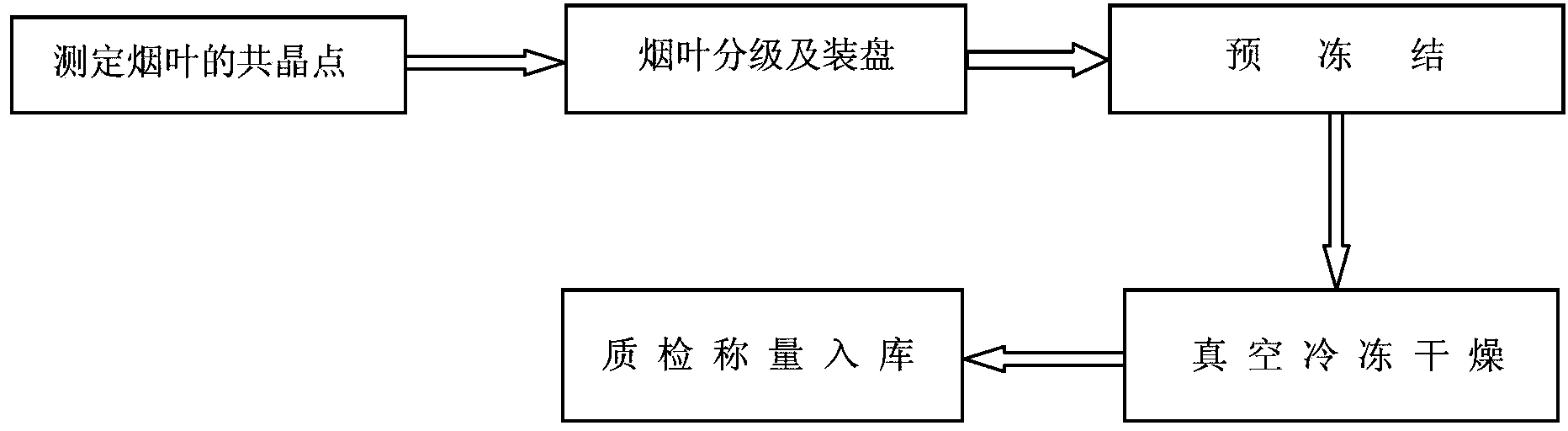

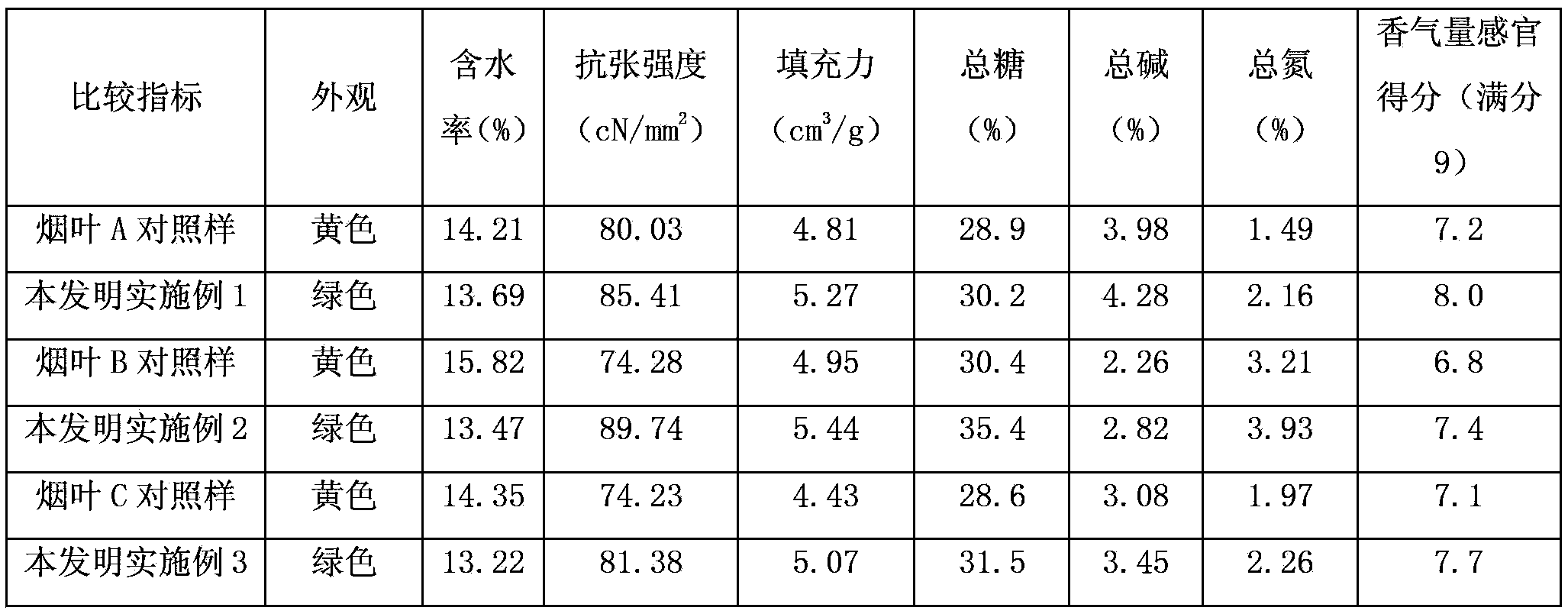

[0025] Tobacco leaves of A are collected, sundries and moldy parts of diseases, insects and insects are removed, graded and processed, and packed into trays. The eutectic point was measured to be -15°C, and the pre-freezing temperature was set to -25°C.

[0026] Take 10kg of A tobacco leaf and pack it into a tray with a thickness of 20mm. Lower the temperature of the freezer to the pre-freezing temperature, put the tobacco leaf tray into the freezer, and keep it for 1.5 hours. The frozen tobacco leaves are placed in a vacuum drying chamber for sublimation drying. First, vacuumize to maintain the vacuum degree in the warehouse between 130 and 170pa, and supply heat to the warehouse through the heating plate. The maximum temperature of the heating plate is set at 40°C. When the temperature of the heating plate and the temperature of the tobacco leaves both reach 40°C, stop heating.

[0027] Break the vacuum in the vacuum drying chamber, take out the tobacco leaves, and put th...

Embodiment 2

[0029] Harvest B tobacco leaves, remove sundries and moldy parts of diseases, pests, and pack them into trays after grading.

[0030] Tobacco leaf B was taken, and its eutectic point was measured to be -13°C, and the pre-freezing temperature was set to -25°C.

[0031] Take 10kg of B tobacco leaves and put them on a tray with a thickness of 15mm. Lower the temperature of the freezer to the pre-freezing temperature, put the tobacco leaf tray into the freezer, and keep it for 1.5 hours. The frozen tobacco leaves are placed in a vacuum drying chamber for sublimation drying. First, vacuumize to maintain the vacuum degree in the bin between 140 and 180pa, and supply heat to the bin through the heating plate. The maximum temperature of the heating plate is set at 45°C. When both the temperature of the heating plate and the temperature of the tobacco leaves reach 45°C, stop heating;

[0032] Break the vacuum in the vacuum drying chamber, take out the tobacco leaves, and put them in...

Embodiment 3

[0034] Harvest C tobacco leaves, remove sundries and moldy parts of diseases, insects and insects, and pack them into trays after grading;

[0035] Tobacco leaf C was taken, and its eutectic point was measured to be -17°C, and the pre-freezing temperature was set to -30°C.

[0036] Take 10 kg of C tobacco leaves and pack them into a tray with a thickness of 30 mm. Lower the temperature of the freezer to the pre-freezing temperature, put the tobacco leaf tray into the freezer, and keep it for 2 hours. The frozen tobacco leaves are placed in a vacuum drying chamber for sublimation drying. First, evacuate to maintain the vacuum degree in the warehouse between 90 and 130pa, and supply heat to the warehouse through the heating plate. The maximum temperature of the heating plate is set at 50°C. When the temperature of the heating plate and the temperature of the tobacco leaves both reach 50°C, stop heating;

[0037] Break the vacuum in the vacuum drying chamber, take out the toba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com