Blended dehumidifying film and preparation method thereof

A wet film and blending technology, applied in the field of blended dehumidification film and its preparation, can solve the problems of limited moisture absorption capacity, easy rupture of moisture absorption materials, low moisture absorption stability, etc., and achieve the effects of stable structure and improved moisture absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

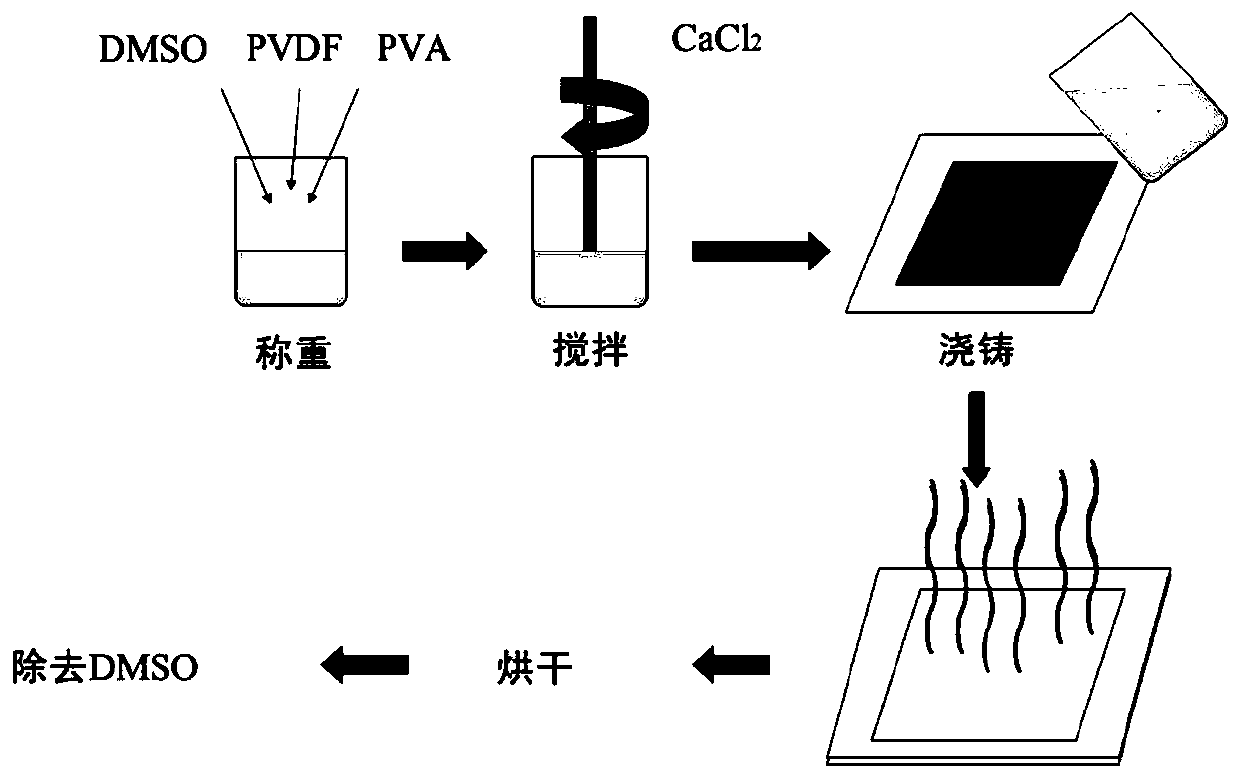

[0041] The embodiment of the present invention proposes a method for preparing a blended dehumidification membrane, which includes the following steps:

[0042] a) Drying the crystalline hydrophobic polymer and polyvinyl alcohol (PVA) separately for subsequent use;

[0043] b) successively adding the PVA obtained in step a) and the crystalline hydrophobic polymer obtained in step a) to the solvent as solutes, and after mixing, adding inorganic hygroscopic particles to obtain a casting solution;

[0044] c) Scraping the film by using the casting solution obtained in step b) to obtain a blended dehumidification film.

[0045] The embodiment of the present invention blends specific multi-component polymers, uses crystal grain aggregates of crystalline hydrophobic polymers as the skeleton, and hydrophilic polymer PVA as a moisture absorption channel and grain aggregate binder, and inorganic moisture absorption Particles are used as fast moisture-absorbing carriers, and the method o...

Embodiment 1

[0070] Example 1 A kind of preparation method of blend dehumidification film

[0071] a) Place PVDF and PVA in an oven at 50°C for 4 hours to dry for later use.

[0072] b) Using dimethyl sulfoxide (DMSO) as a solvent, PVA and PVDF as solutes, and the concentration of the casting solution is 20 wt%. First mix a certain amount of PVA and DMSO, and stir in a water bath at 60°C-90°C for 1 hour; after the PVA is completely dissolved in DMSO, add a certain amount of PVDF and continue stirring for 1 hour; Particles of calcium chloride were added and stirred for 2 hours, and vacuum degassed for 1 hour to obtain a uniform casting solution.

[0073] c) Use a 0.5mm scraping rod (heat the scraping rod to 60°C) to scrape the film on the PE film, place the film in the air for 48 hours, and store it in a vacuum seal after the solvent in the film is completely evaporated.

[0074] Among them, the mass ratio of PVA to PVDF is 1:4; the mass ratio of calcium chloride to polymer blend is 1:4...

Embodiment 2

[0075] Example 2 A kind of preparation method of blend dehumidification film

[0076] Same as Example 1, the difference is that the concentration of the casting solution is 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com