Hollow glass and manufacturing method thereof

A production method and glass technology, applied in the field of insulating glass with molecular sieves as spacers and its production, can solve the problems of expensive equipment, shortened life, bumps, etc., and achieve the effects of reducing production costs, prolonging service life, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

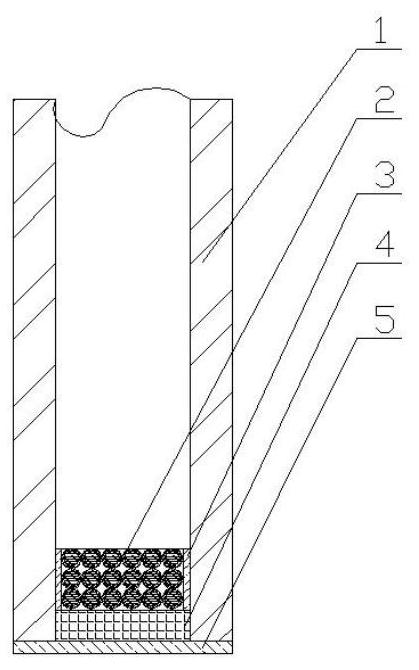

[0089] Embodiment 1 of the present invention provides a kind of insulating glass with molecular sieve as spacer, such as figure 1 and Figure 10 As shown, it includes two pieces of glass 1, four spacers 2, a first seal 3, a second seal 4 and a third seal 5; two pieces of glass 1 are provided with a spacer 2; the two ends of each spacer 2 They are respectively cut into 45° angles, and are arranged on the periphery of the glass 1 in four sections to form a closed spacer frame; the first seal 3 is arranged between the glass 1 and the spacer bar 2; the second seal 4 and the third seal 5 are both It is arranged between two adjacent pieces of glass 1 and is located on the outer side of the spacer bar 2 in turn.

[0090] Among them, the distance between two adjacent pieces of glass 1 is 9mm, the glass 1 is ordinary glass, the spacer 2 is a molecular sieve spacer with a dense layer, the first seal 3 is butyl rubber, and the second seal 4 is a double set 5 parts silicone sealant, the...

Embodiment 2

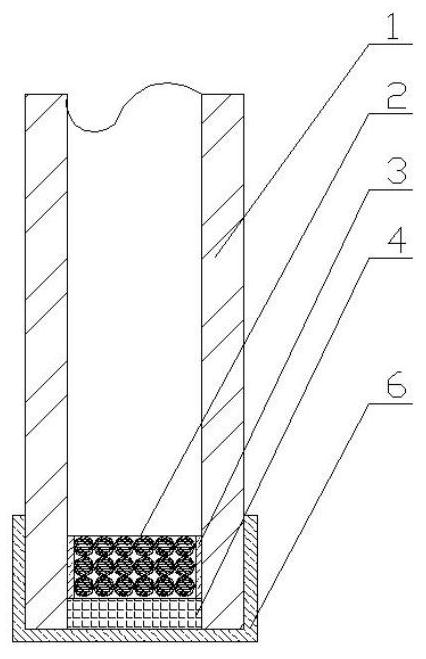

[0099] Embodiment 2 of the present invention provides a kind of insulating glass with molecular sieve as spacer, such as figure 2 and Figure 11 As shown, it includes two pieces of glass 1, four spacers 2, a first seal 3, a second seal 4 and a fourth seal 6; two pieces of glass 1 are provided with a spacer 2; the spacer 2 is cut at a right angle, Four spacers 2 are arranged on the periphery of the glass 1 in four sections to form a closed spacer frame; the first seal 3 is arranged between the glass 1 and the spacer 2; the second seal 4 is arranged between two adjacent pieces of glass 1 between, and located on the outer edge of the spacer bar 2; the fourth seal 6 is arranged on the sides and outer surfaces of two adjacent pieces of glass 1.

[0100] Among them, the distance between two adjacent pieces of glass 1 is 27mm, the glass 1 is ultra-white glass, the spacer 2 is a molecular sieve spacer with a reinforced layer prepared by a mold, the first seal 3 is a hot-melt pressur...

Embodiment 3

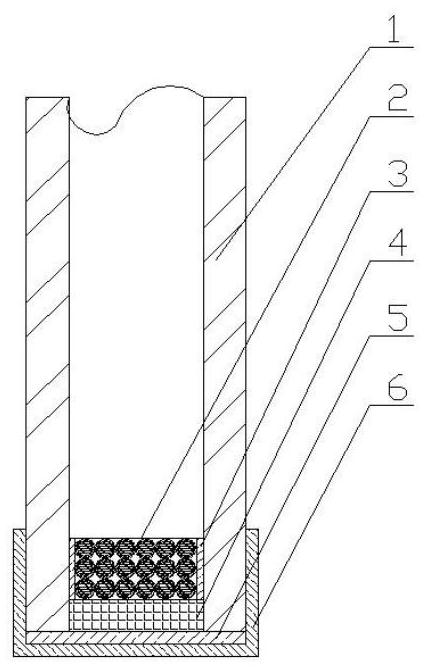

[0108] Embodiment 3 of the present invention provides a kind of insulating glass with molecular sieve as spacer, such as image 3 and Figure 12 As shown, it includes two pieces of glass 1, spacer bar 2, first seal 3, and second seal 4, third seal 5 and fourth seal 6; spacer bar 2 is arranged between two pieces of glass 1; spacer bar 2 has The bending notch is bent into a closed rectangular spacer frame by means of bending and arranged around the glass 1; the first seal 3 is arranged between the glass 1 and the spacer 2; the second seal 4 and the third seal 5 are arranged on Between two adjacent pieces of glass 1 , and sequentially located on the outer side of the spacer bar 2 ; the fourth seal 6 is arranged on the sides and outer surfaces of the two adjacent pieces of glass 1 .

[0109] Among them, the distance between two adjacent pieces of glass 1 is 15mm, the glass 1 is frosted glass, the spacer 2 is a spacer with a bending gap prepared by a mold, the first seal 3 is PUR ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com