Cellulose nanofibril reinforced acrylic fiber as well as preparation method and application thereof

A technology of nanofibrils and acrylic fibers, which is applied in the direction of cellulose/protein conjugated rayon, rayon manufacturing, fiber chemical characteristics, etc. It can solve the problem of small size of nano whiskers, high preparation cost, and unfavorable large-scale industrial application and other problems, to achieve the effect of strengthening acrylic fiber and improving hygroscopic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

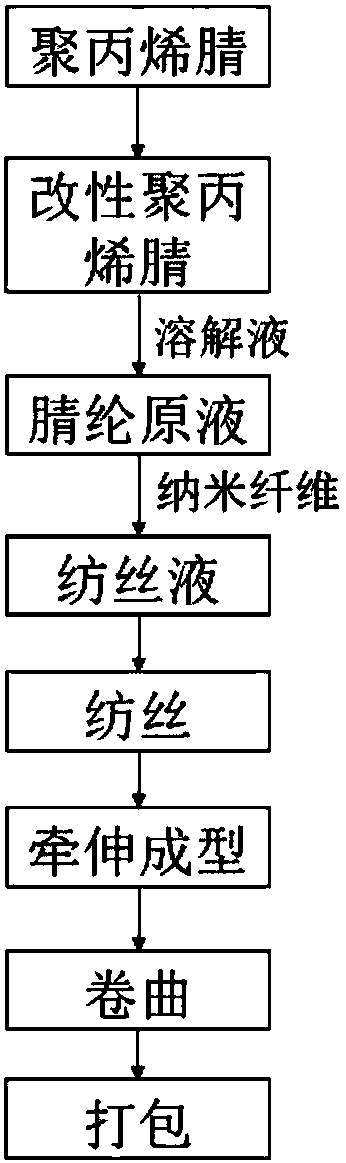

Method used

Image

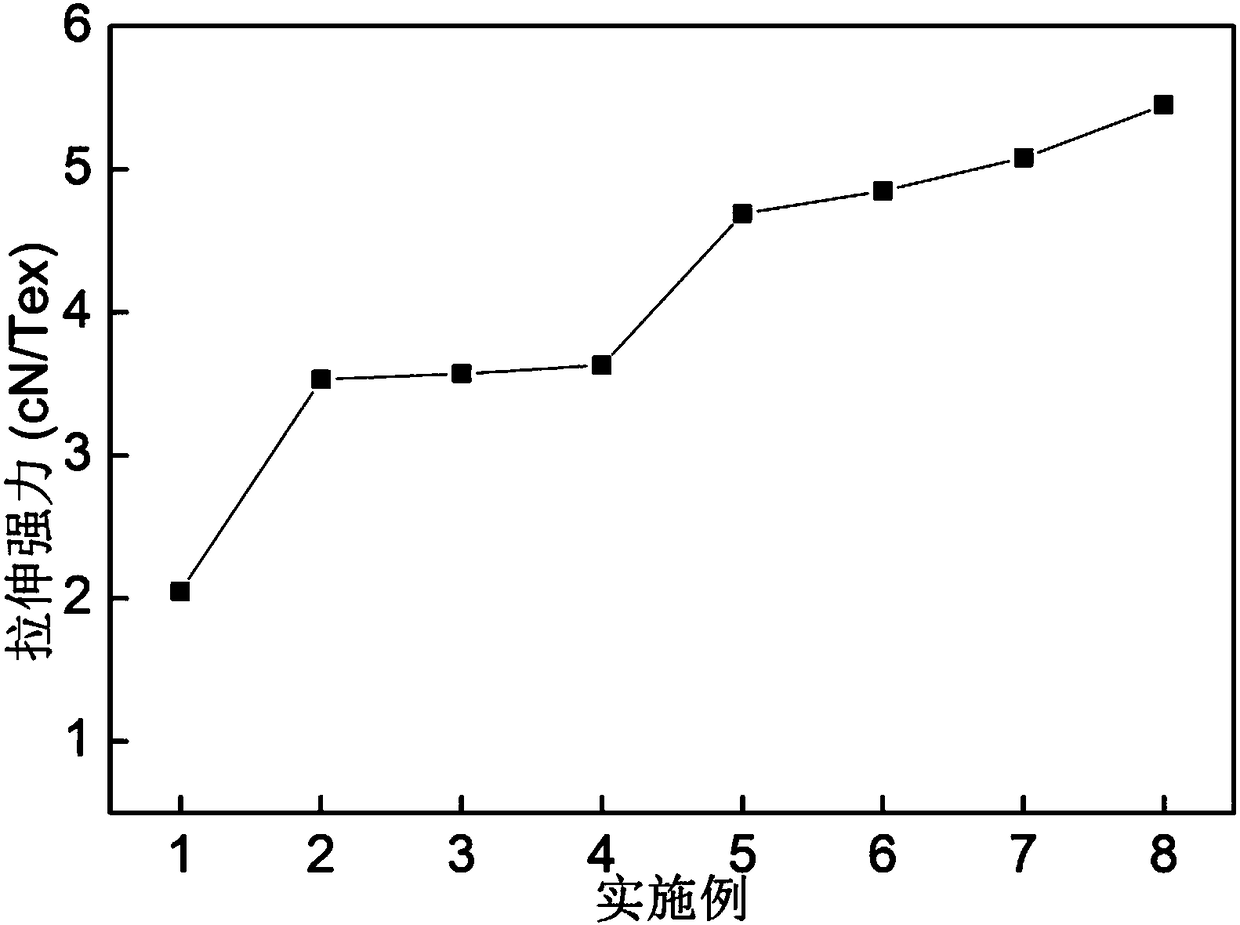

Examples

Embodiment 1

[0042] The preparation method of the acrylic fiber without adding is as follows:

[0043] (1) Polyacrylonitrile (PAN) was treated at 85°C for 30 minutes in an aqueous solution with a mass fraction of 1% sodium hydroxide and 95% ethanol, then washed with water until neutral, and dried at 105°C for 5 hours. The pretreated polyacrylonitrile was dissolved in dimethylformamide to prepare an acrylic fiber stock solution with a mass fraction of polyacrylonitrile of 10%. The acrylic fiber spinning solution was vacuum defoamed at -0.1MPa for 10h.

[0044] (2) the acrylic fiber spinning solution after the defoaming is spun on the spinning machine, and the massfraction that the sodium sulfate, zinc sulfate and sulfuric acid are formed is respectively 20%, 5% and 10% after the coagulation bath coagulation molding, adjusts the draft The stretching ratio is 5 times, and the acrylic fibers are collected after washing and drying.

Embodiment 2

[0046] The acrylic fiber reinforced by inorganic nanometer silicon carbide whiskers, its preparation method is as follows:

[0047] (1) Polyacrylonitrile (PAN) was treated at 85°C for 30 minutes in an aqueous solution with a mass fraction of 1% sodium hydroxide and 95% ethanol, then washed with water until neutral, and dried at 105°C for 5 hours. The pretreated polyacrylonitrile was dissolved in dimethylformamide to prepare an acrylic fiber stock solution with a mass fraction of polyacrylonitrile of 10%.

[0048] (2) Add inorganic nano-silicon carbide with a diameter of 20nm and a length of 800nm into the acrylic fiber stock solution, so that the mass ratio of inorganic nano-silicon carbide and PAN reaches 1:100, and mix it to form an acrylic fiber spinning solution. The acrylic fiber spinning solution was vacuum defoamed at -0.1MPa for 10h.

[0049] (3) the acrylic fiber spinning solution after the defoaming is spun on the spinning machine, and the massfraction that sodium...

Embodiment 3

[0051] Nano cellulose whisker reinforced acrylic fiber, its preparation method is as follows:

[0052] (1) Polyacrylonitrile (PAN) was treated at 85°C for 30 minutes in an aqueous solution with a mass fraction of 1% sodium hydroxide and 95% ethanol, then washed with water until neutral, and dried at 105°C for 5 hours. The pretreated polyacrylonitrile was dissolved in dimethylformamide to prepare an acrylic fiber stock solution with a mass fraction of polyacrylonitrile of 15%.

[0053] (2) Add nanocellulose whiskers (NCC) with a diameter of 5nm and a length of 200nm into the acrylic fiber stock solution, so that the mass ratio of NCC and PAN reaches 1:100, and mix it to form an acrylic fiber spinning solution. The acrylic fiber spinning solution was vacuum defoamed at -0.1MPa for 10h.

[0054] (3) the acrylic fiber spinning solution after the defoaming is spun on the spinning machine, and the massfraction that sodium sulfate, zinc sulfate and sulfuric acid are formed is respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com