Method for preparing nano-functional fiber with moisture absorption, sweat releasing and bacterial resistance

A moisture-absorbing and sweat-wicking, nano-functional technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of unrealistic industrial production, high cost, and moisture permeability, and achieve excellent moisture-wicking performance and equipment Low requirement, effect of improving hygroscopic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

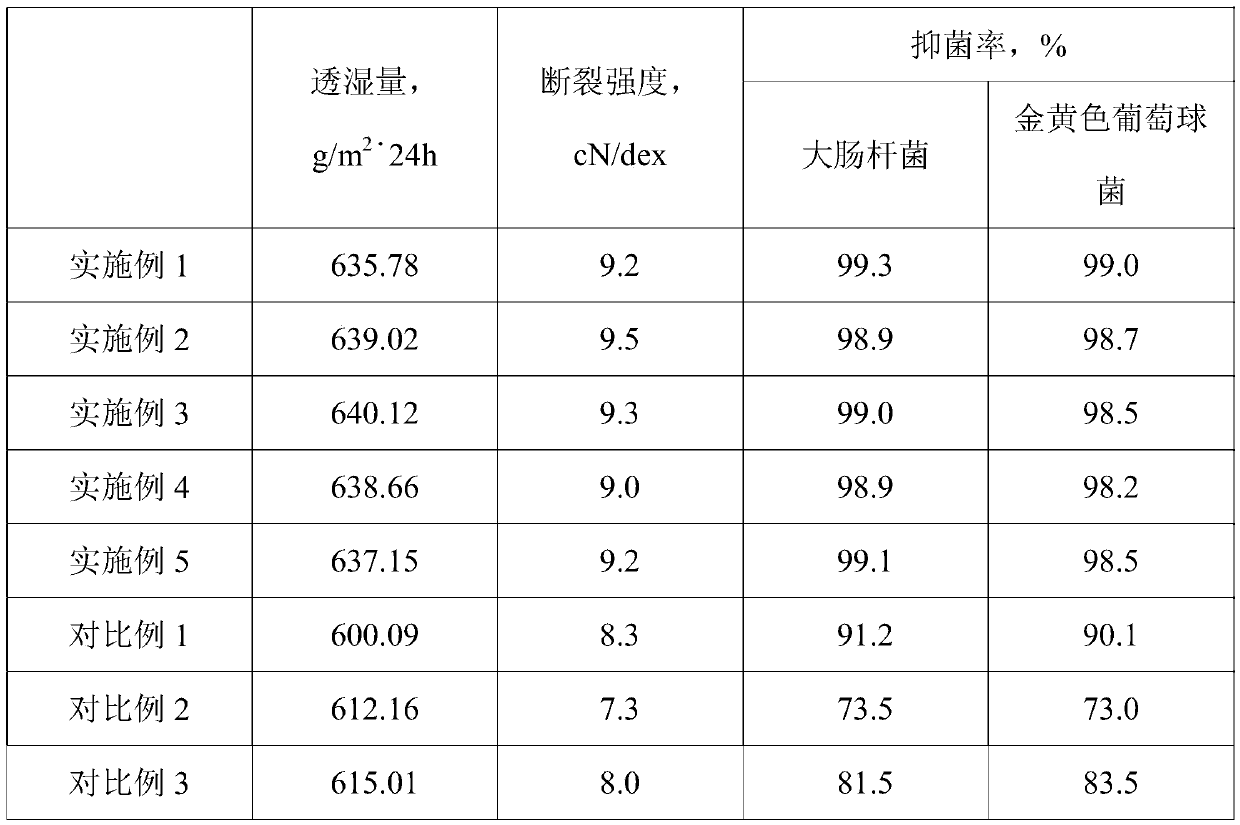

Examples

Embodiment 1

[0032] A preparation method of a nano-functionalized moisture-absorbing and sweat-wicking antibacterial fiber, comprising the following steps:

[0033] (1) Dissolve sodium alginate in deionized water at 40°C to obtain a sodium alginate solution with a concentration of 1g / ml; then use a syringe to inject the sodium alginate solution into 5-10°C with a concentration of 3g / ml In the calcium chloride solution, keep the mass ratio of sodium alginate and calcium chloride at 1:5, stir for 4 hours to obtain a dispersion of sodium alginate microspheres, filter, and dry to obtain sodium alginate microspheres;

[0034] (2) 4g of nano-montmorillonite powder is added to deionized water, 0.015g of cetyltrimethylammonium bromide is added, and ultrasonic treatment is performed at a power of 500W to obtain an organic montmorillonite dispersion, and 1g of the above-mentioned preparation is added. After stirring and mixing the obtained sodium alginate microspheres, add a mixed emulsion composed ...

Embodiment 2

[0039] A preparation method of a nano-functionalized moisture-absorbing and sweat-wicking antibacterial fiber, comprising the following steps:

[0040] (1) Dissolve sodium alginate in deionized water at 40°C to obtain a sodium alginate solution with a concentration of 5g / ml; then use a syringe to inject the sodium alginate solution into 5-10°C with a concentration of 5g / ml In the calcium chloride solution, keep the mass ratio of sodium alginate and calcium chloride at 1:5, stir for 8 hours to obtain a dispersion of sodium alginate microspheres, filter, and dry to obtain sodium alginate microspheres;

[0041] (2) 4g of nano-montmorillonite powder is added to deionized water, 0.033g of hexadecyltrimethylammonium bromide is added, and ultrasonic treatment is performed at a power of 500W to obtain an organic montmorillonite dispersion, and 1g of the above-mentioned preparation is added. After stirring and mixing the obtained sodium alginate microspheres, add a mixed emulsion compo...

Embodiment 3

[0046] A preparation method of a nano-functionalized moisture-absorbing and sweat-wicking antibacterial fiber, comprising the following steps:

[0047] (1) Dissolve sodium alginate in deionized water at 40°C to obtain a sodium alginate solution with a concentration of 2g / ml; then use a syringe to inject the sodium alginate solution into 5-10°C with a concentration of 3g / ml In the calcium chloride solution, keep the mass ratio of sodium alginate and calcium chloride at 1:5, stir for 5 hours to obtain a dispersion of sodium alginate microspheres, filter, and dry to obtain sodium alginate microspheres;

[0048] (2) 4g of nano-montmorillonite powder is added to deionized water, 0.02g of cetyltrimethylammonium bromide is added, and ultrasonic treatment is performed at a power of 500W to obtain an organic montmorillonite dispersion, and 1g of the above-mentioned preparation is added. After stirring and mixing the obtained sodium alginate microspheres, add a mixed emulsion composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com