Polyester fiber with functions of wetting, moisture transmitting and quick drying and fabric thereof

A technology of copolyester and ester, which is applied in the field of textile fibers to achieve the effect of improving moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

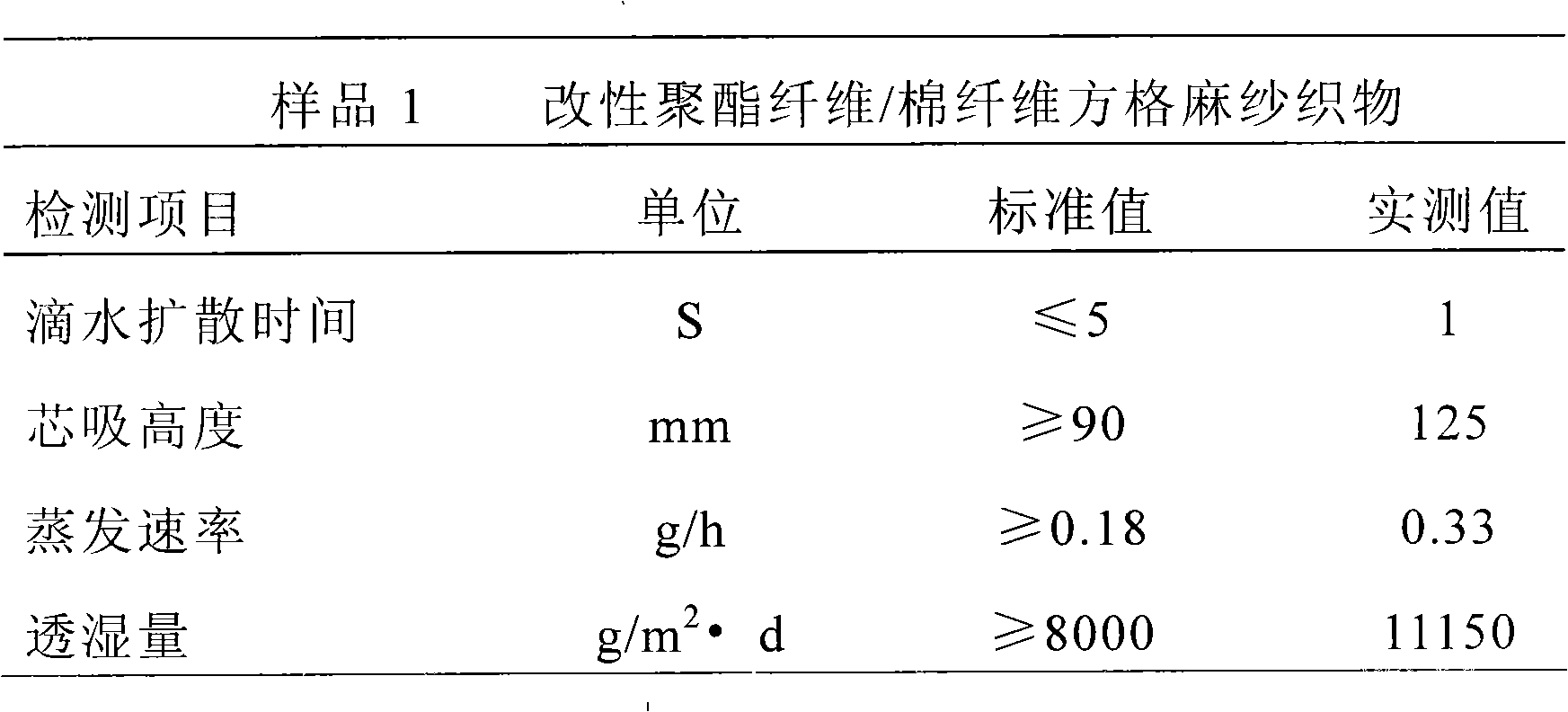

Examples

Embodiment 1

[0032] Using ethylene glycol and terephthalic acid (the molar ratio of ethylene glycol and terephthalic acid is 1.3:1) as raw materials, it is produced in a semi-continuous direct esterification device at 258°C after 2.5 hours to complete the esterification reaction. Ethylene terephthalate. Then add the diethylene glycol isophthalate-5-sodium sulfonate of 4.5mol% (in total moles of terephthalic acid) prepared in advance, 0.45mol% (in total mass of terephthalic acid) ) polyethylene glycol and 1.5% (based on the total mass of terephthalic acid) ground inorganic nanopowder SiO 2 , at 0.032wt% catalyst Sb 2 o 3 The polycondensation reaction is completed in the presence of (based on the total mass of terephthalic acid), the residual pressure of the system is less than 80 Pa, and the final reaction temperature is controlled at 282°C. The power of the mixer in the reaction process is controlled to obtain a functional copolyester masterbatch with an intrinsic viscosity of 0.535dl / g...

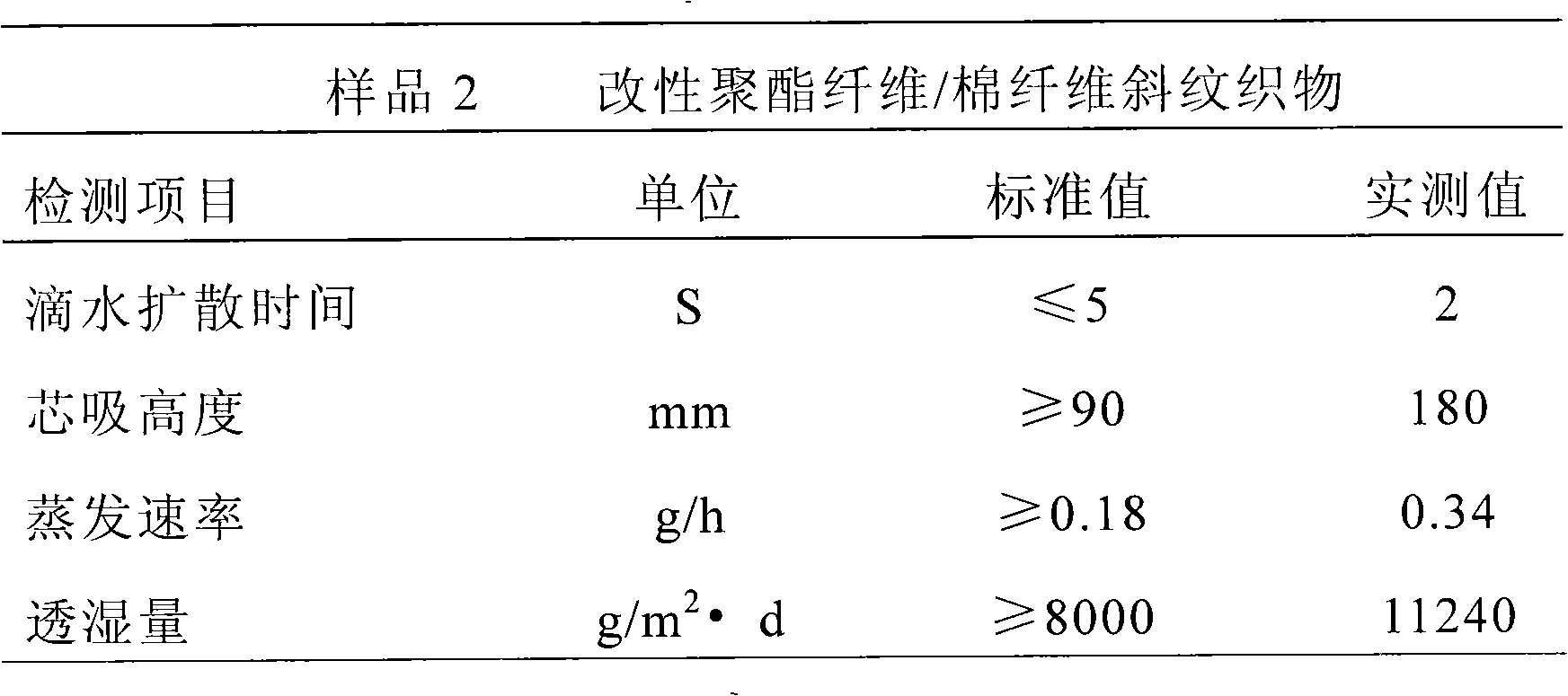

Embodiment 2

[0038] According to the mol ratio of ethylene glycol and terephthalic acid in Example 1, the esterification and polycondensation process conditions are the same as in Example 1. Diethylene glycol isophthalate-5-sodium sulfonate, 0.55mol% (total mass of terephthalic acid) Polyethylene glycol and polytetramethylene glycol (the two add in equimolar ratio) mixture, and 1.3% (in terms of the total mass of terephthalic acid) inorganic nano-powder ZrO after grinding 2 , to prepare a functional copolyester masterbatch with an intrinsic viscosity of 0.526dl / g.

[0039] The obtained above-mentioned functional copolyester masterbatch is mixed with conventional polyethylene terephthalate (PET) slices with an intrinsic viscosity of 0.665g / dl in a mass ratio of 20:80, pre-crystallized, and dried , and then carry out blending spinning-stretching-heat setting on the ordinary short fiber melt spinning machine and post-processing equipment to make trilobal special-shaped short fibers. The spi...

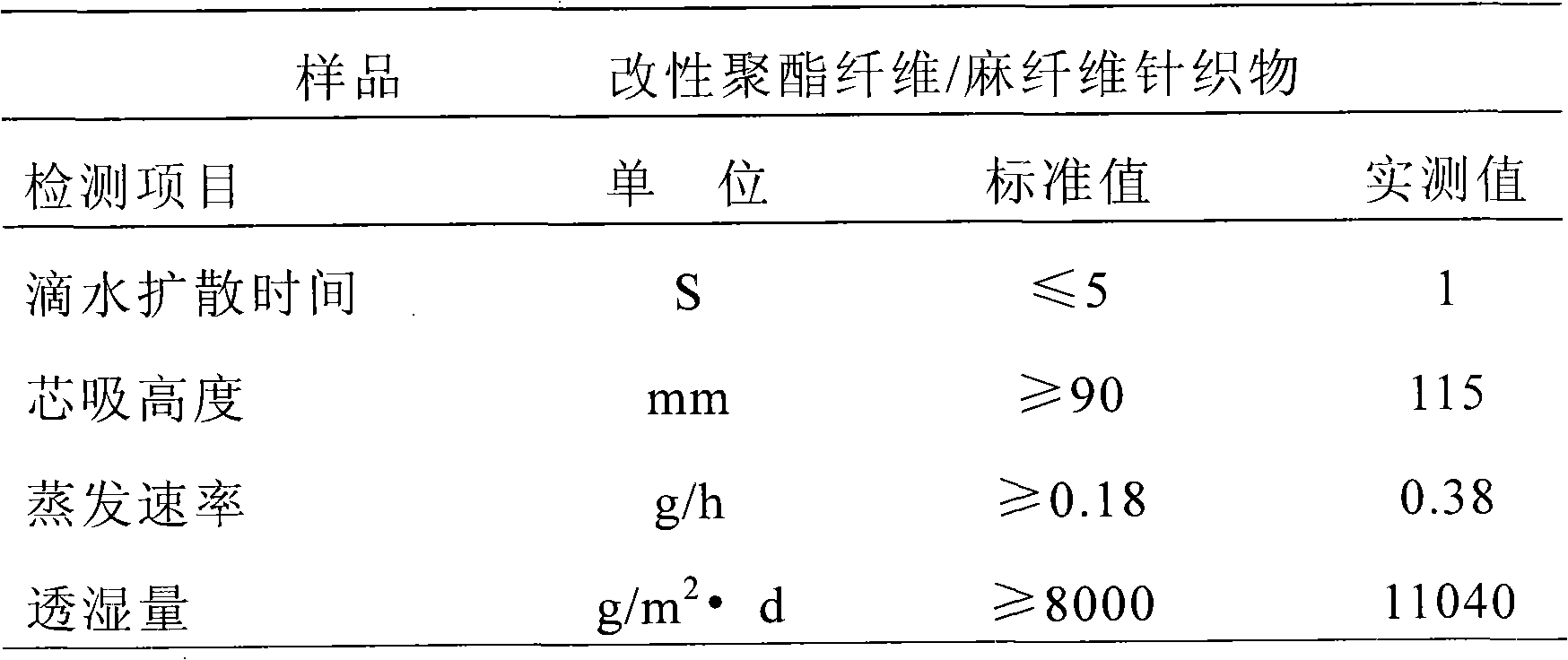

Embodiment 3

[0043] According to the mol ratio of ethylene glycol and terephthalic acid in Example 1, the esterification and polycondensation process conditions are the same as in Example 1. Diethylene glycol isophthalate-5-sodium sulfonate, 0.40mol% (total mass of terephthalic acid) Polyethylene glycol and polypropylene glycol (the two add in equimolar ratio) mixture, and 1.2% (in terms of the total mass of terephthalic acid) inorganic nano-powder TiO after grinding 2 , to prepare a functional copolyester masterbatch with an intrinsic viscosity of 0.551dl / g.

[0044] The obtained above-mentioned functional copolyester masterbatch is mixed with conventional polyethylene terephthalate (PET) slices with an intrinsic viscosity of 0.665g / dl in a mass ratio of 30:70, pre-crystallized, and dried , and then carry out blending spinning-stretching-heat setting on the ordinary short fiber melt spinning machine and post-processing equipment to make five-lobed special-shaped short fibers. The spinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com