Cored micro pipe irrigation system for greenhouse climbing crops

An irrigation system and micro-pipe technology, applied in the field of irrigation, can solve the problems of reducing soil microbial activities of root absorption function, reducing crop quality and yield, and shortening the service life of equipment, so as to achieve good water saving effect, improve water utilization rate, The effect of saving manpower and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

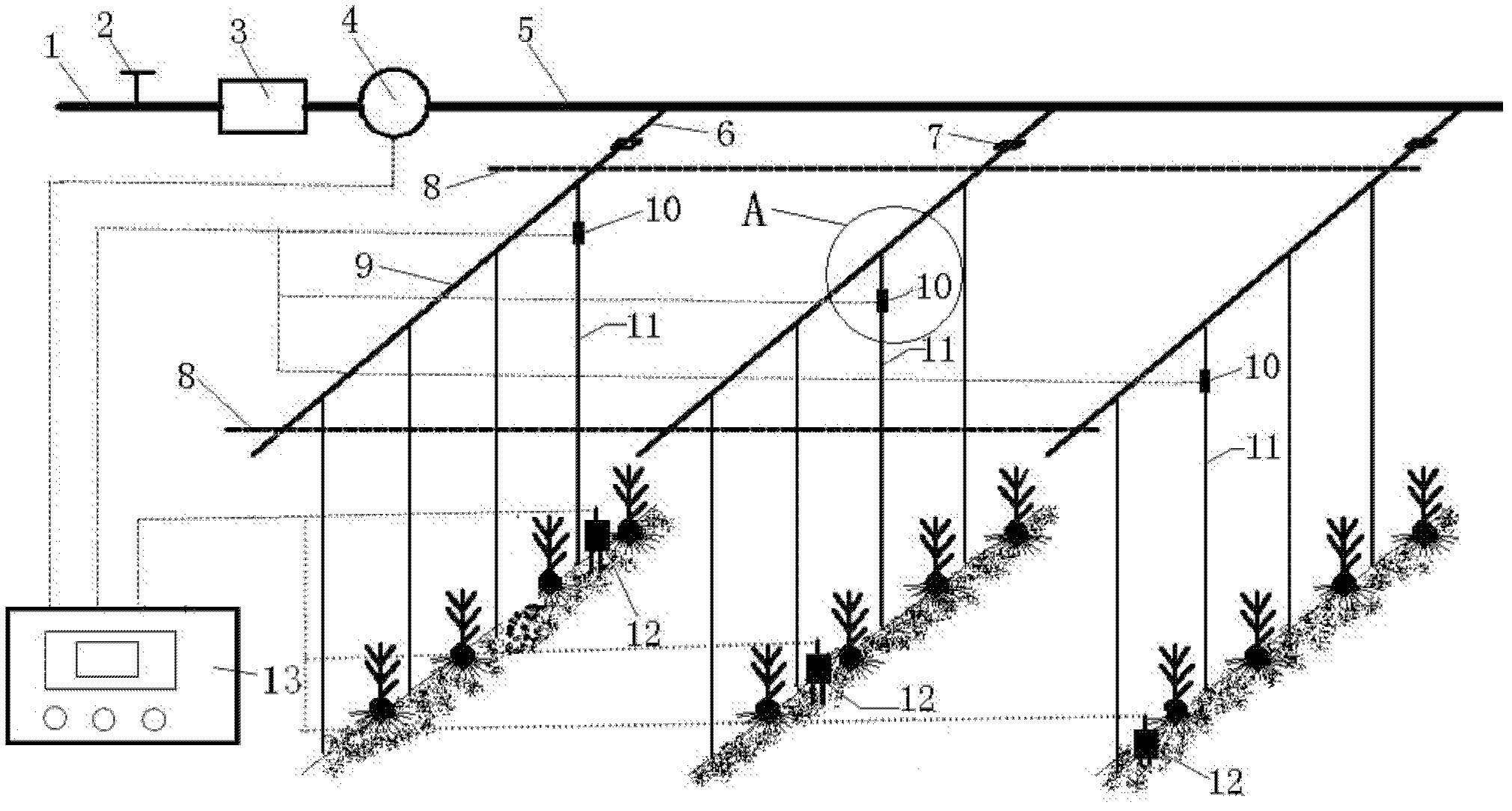

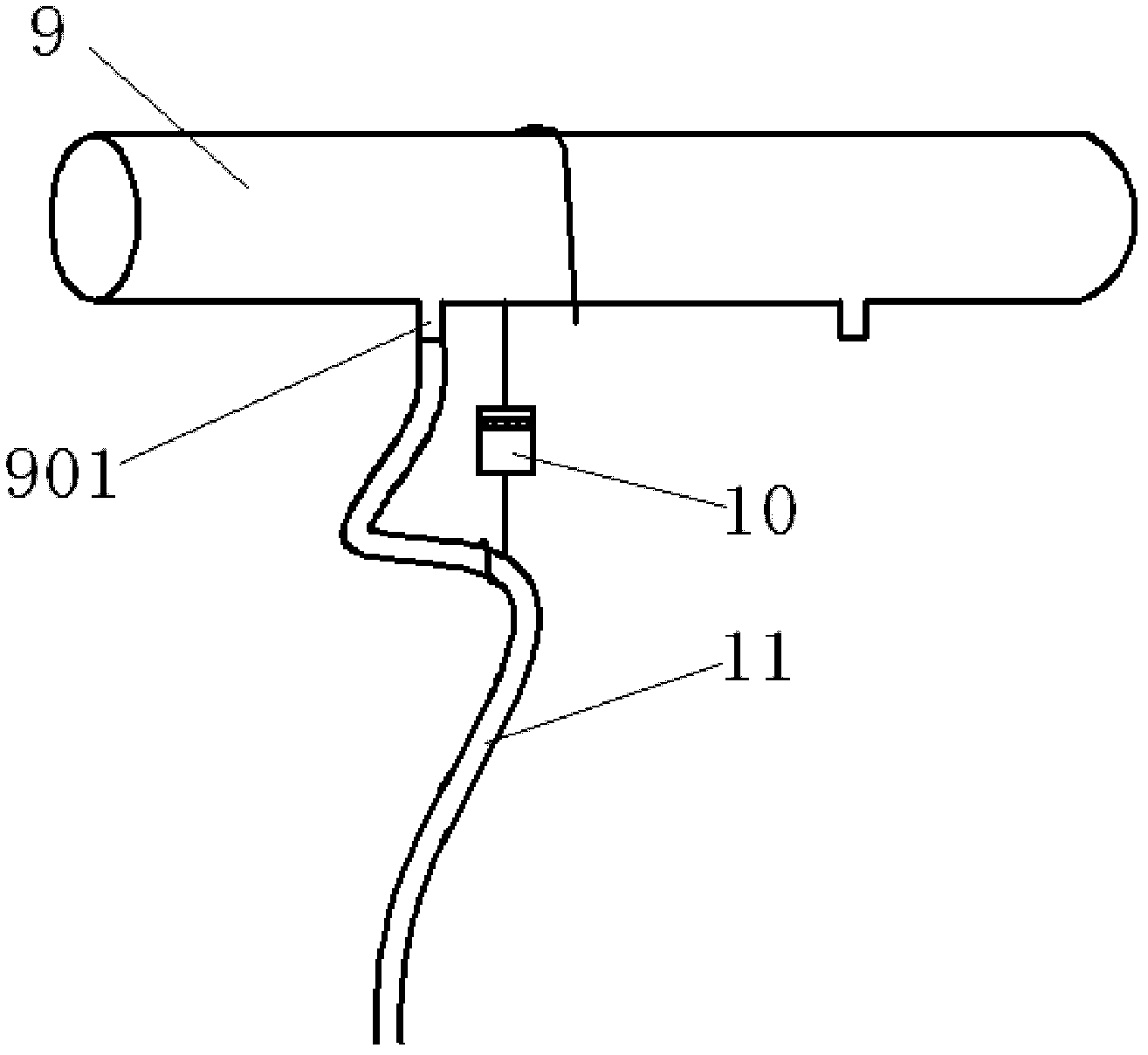

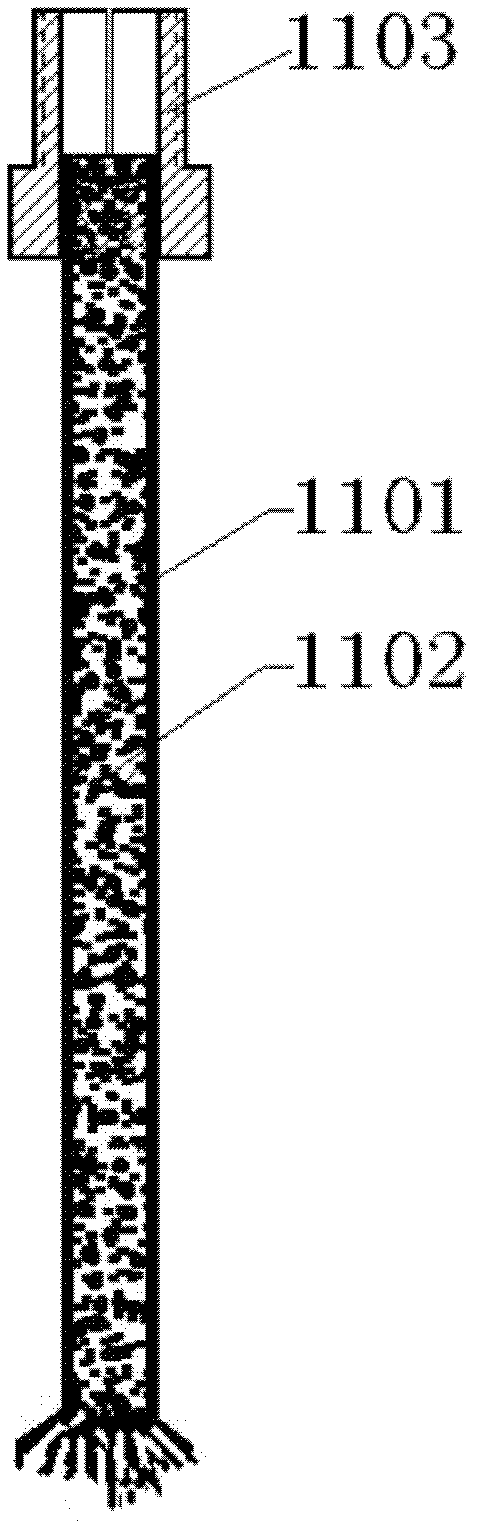

[0033] Such as figure 1 The micropipe irrigation system for greenhouse climbing crops is shown. The micropipe irrigation system for greenhouse climbing crops is mainly composed of the main water inlet pipe 1, the main water source valve 2, the filter 3, the solenoid valve 4, the dry pipe 5, the soft Pipe 6, conversion joint 7, branch pipe support frame 8, branch pipe 9, stress gauge 10, cored micropipe sprinkler 11, soil moisture sensor 12 and controller 13. The main pipe 5 is erected in the greenhouse, and the branch pipe support frame 8 is erected in the greenhouse on one side of the main pipe 5. From the main water source inlet pipe 1 to one end of the main pipe 5, the main water source valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com