Resin composition for water absorbing film, water absorbing film for packing, and manufacturing method thereof

A resin composition and packaging technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as complicated procedures, product contamination, and product quality reduction, and improve preservation quality and effect, improve preservation effect, The effect that the moisture absorption effect is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

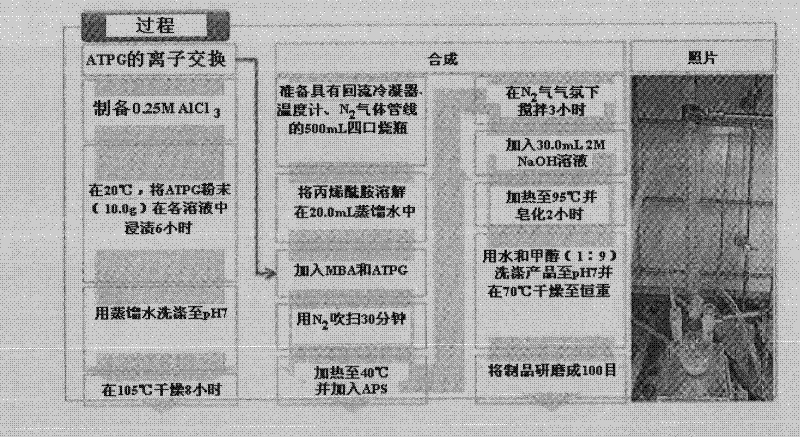

Embodiment 1

[0052] Embodiment 1: Performance analysis of water-absorbing agent

[0053] The characteristics of moisture and each adsorbent are compared, and the substances that are expected to easily absorb moisture in the atmosphere are screened out, and the adsorbents that can physically adsorb moisture in the atmosphere and surrounding liquids are screened out. This is to prevent unwanted reaction by-products due to chemical bonding between moisture and the sorbent when used in food packaging.

[0054] In addition, the manufacturing process of the adsorbent was grasped, so that the substances that minimized the chemical treatment were screened. This is also to reduce the occurrence of problems when used in food packaging.

[0055] In consideration of processability when used in a film, processability of suitable particle size suitable for mixing in a film, and economical efficiency in mass production, easily available materials were mainly selected.

[0056] The substances described ...

Embodiment 2

[0091] Embodiment 2: Feasibility analysis of manufacturing thin films suitable for plates

[0092] Two hygroscopic substances, PAPSS and ATPGAA, were selected through Example 1 above. Studies have been conducted for their use in packaging materials. First, the physical properties and material dispersibility were evaluated after manufacturing a board using common plastic LDPE resin. The development feasibility of the thin film was evaluated through the intermediate step of the final target functional thin film development process-sheet fabrication.

[0093] 2-1: Fabrication and analysis of thin plates

[0094] The board was produced by hot pressing under the conditions of 200° C. and 10 MPa pressure. Use LDPE as the resin for making the board, and the functional substance is PAPSS and ATPGAA selected in the above-mentioned embodiment 1. In order to disperse the two substances evenly on the LDPE resin, the particle size should be less than 1000μm.

[0095] In order to deter...

Embodiment 3

[0112] Embodiment 3: the making of film

[0113] 3-1: Manufacture of film

[0114] According to the experimental results of making plates, the dispersion effect of the dispersant is not ideal due to the agglomeration phenomenon of the powdery functional substances when they are in contact. Therefore, mechanical dispersion was selected, and after primary dispersion was performed by manufacturing a pallet by compounding with resin, secondary dispersion was performed by a film extrusion process.

[0115] Mixing was carried out by NPI Co., Ltd. in Wonju, Gangwon-do. A twin-screw extrusion molding device was used, and LLDPE-hanwha 3126 for film was used as the resin. In order to minimize the decrease in physical properties due to the particle size, the particle size of PAPSS and ATPGAA was ground to 100 mesh and used. The content of functional substances inside the pallet was prepared at 10% by weight. The temperature setting of each section is: first cylinder (cylinder) 150°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com