Double-sided high-strength antistatic fabric and production process

An anti-static fabric, high-strength technology, used in layered products, synthetic resin layered products, textiles, etc., can solve the problems of insufficient anti-static effect, poor stability of anti-static fabric substrates, etc. The effect of high toughness and strong tensile ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

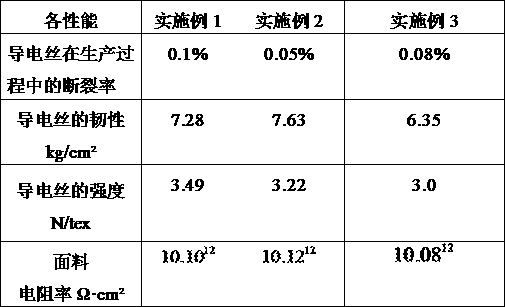

Embodiment 1

[0070] S1, configure carbon fiber, oxidize the PAN precursor in an oxidizing atmosphere at 200°C, and then put the PAN precursor into an inert atmosphere at 3600° and a mixed solution of glucose and benzoyl peroxide to carbonize into a carbonized liquid; then Ai-Ti grain refiner is added to refine crystals, and then the carbonized liquid is graphitized and surface treated to obtain carbon fibers.

[0071] S2, configure conductive filaments, spin the carbon fibers obtained in S1 into carbon fiber filaments with a spinning machine, and then immerse the surface of the carbon fiber filaments in stannous chloride solution for 5h, and then use a parallel twister to spin the 3D of 7D. A single carbon fiber yarn is composited into a conductive wire;

[0072] S3, configure polyester yarn, use a twisting machine to wind one 7D DTY network filament polyester single yarn on another 7D DTY network filament polyester single yarn, and the two polyester single yarns form holes of different si...

Embodiment 2

[0078] S1, configure carbon fiber, oxidize the PAN precursor in an oxidizing atmosphere at 250°C, and then put the PAN precursor into an inert atmosphere at 3700°C and a mixed solution of glucose and benzoyl peroxide to carbonize into a carbonized liquid; then The Al-Fe grain refiner is added to refine the crystal, and then the carbonized liquid is graphitized and surface-treated to obtain carbon fibers.

[0079] S2, configure conductive filaments, spin the carbon fibers obtained in S1 into carbon fiber filaments with a spinning machine, and then immerse the surface of the carbon fiber filaments in stannous chloride solution for 6 hours, and then use a twisting machine to spin 5D thick filaments. 4 single carbon fiber yarns are composited into a conductive wire;

[0080] S3, configure polyester yarn, use a twisting machine to wind one 7D DTY network filament polyester single yarn on another 7D DTY network filament polyester single yarn, and the two polyester single yarns form ...

Embodiment 3

[0086] S1, configure carbon fiber, oxidize the PAN precursor in an oxidizing atmosphere of 300°C, and then put the PAN precursor into an inert atmosphere at 3800°C and a mixed solution of glucose and benzoyl peroxide for carbonization into a carbonized liquid; then The Al-Zr grain refiner is added to refine the crystal, and then the carbonized liquid is graphitized and surface-treated to obtain carbon fibers.

[0087] S2, configure conductive filaments, spin the carbon fibers obtained in S1 into carbon fiber filaments with a spinning machine, and then immerse the surface of the carbon fiber filaments in a stannous chloride solution for 7 hours, and then use a twisting machine to spin the 3D thick filaments. 6 single carbon fiber yarns are combined into a conductive wire;

[0088] S3, configure polyester yarn, use a twisting machine to wind one 7D DTY network filament polyester single yarn on another 7D DTY network filament polyester single yarn, and the two polyester single ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com