Patents

Literature

66results about How to "Strong tensile properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of gold and palladium-plated bonding copper wire for encapsulation

InactiveCN106086962AAvoid breakingConsistent deformationSolid-state devicesSemiconductor/solid-state device manufacturingCopper wireGold layer

The invention discloses a production technology of a gold and palladium-plated bonding copper wire for the field of semiconductor integrated circuit encapsulation. The production technology comprises the technological process of carrying out coarse drawing, annealing, palladium layer electroplating, fine drawing, annealing, gold layer electroplating and cleaning on a microelement-added central copper rod treated through a continuous casting technology, so as to prepare the gold and palladium-plated bonding copper wire excellent in physical and chemical property. The technological process is characterized in that only one-time coarse drawing and one-time fine drawing are carried out, and a gold plating technology is carried out after a target wire diameter is achieved through the fine drawing. According to the gold and palladium-plated bonding copper wire produced through the technology, the wire breakage rate during the drawing process is relatively low, the combination property of a palladium-plated layer and a gold-plate layer is good, and the binding reliability and stability of the bonding wire are greatly improved.

Owner:上海铭沣科技股份有限公司

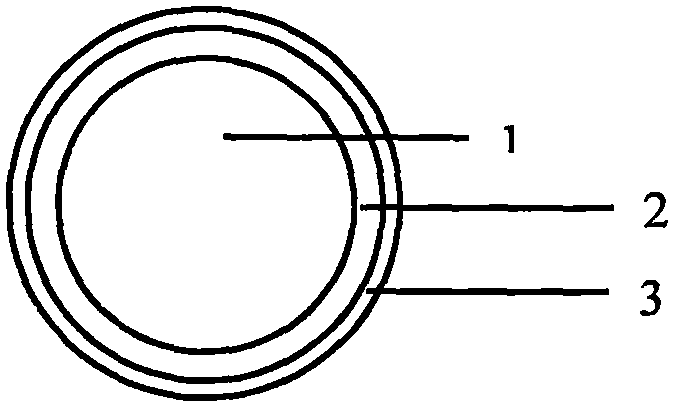

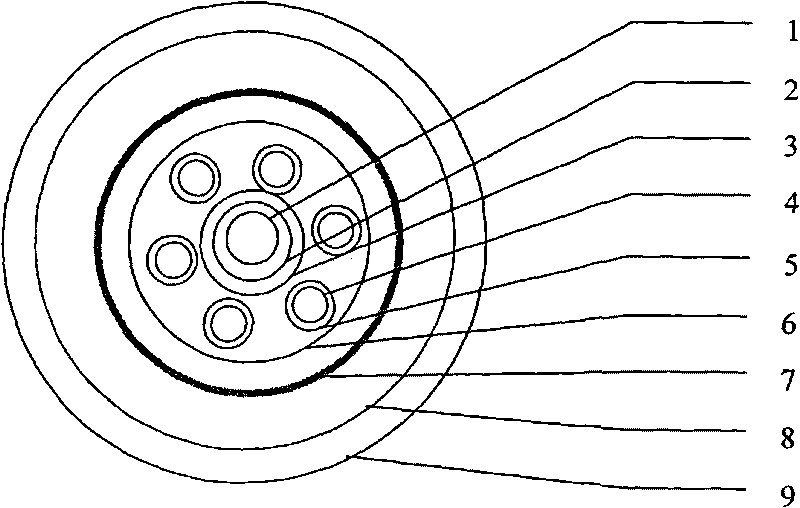

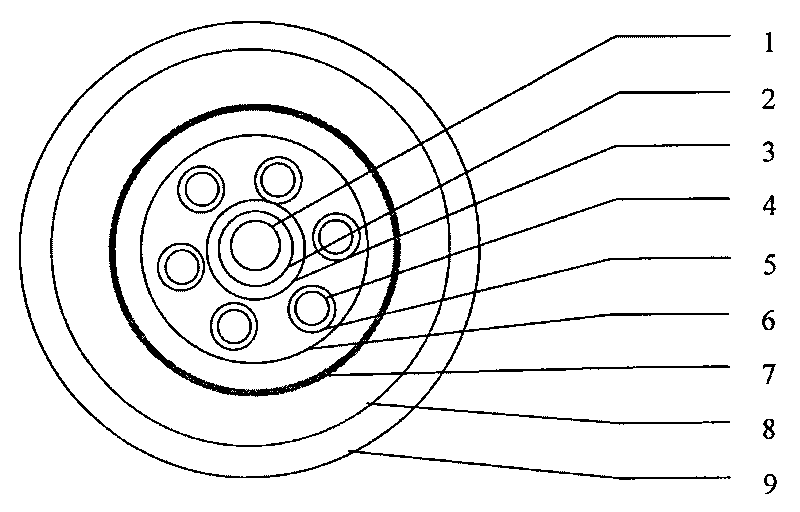

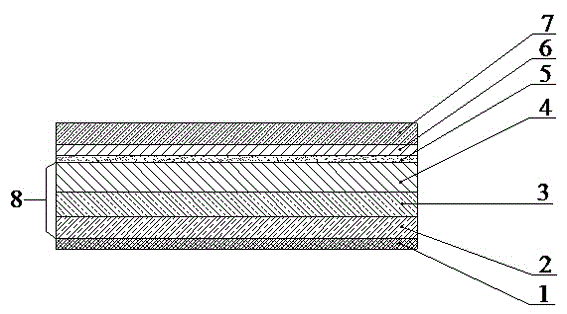

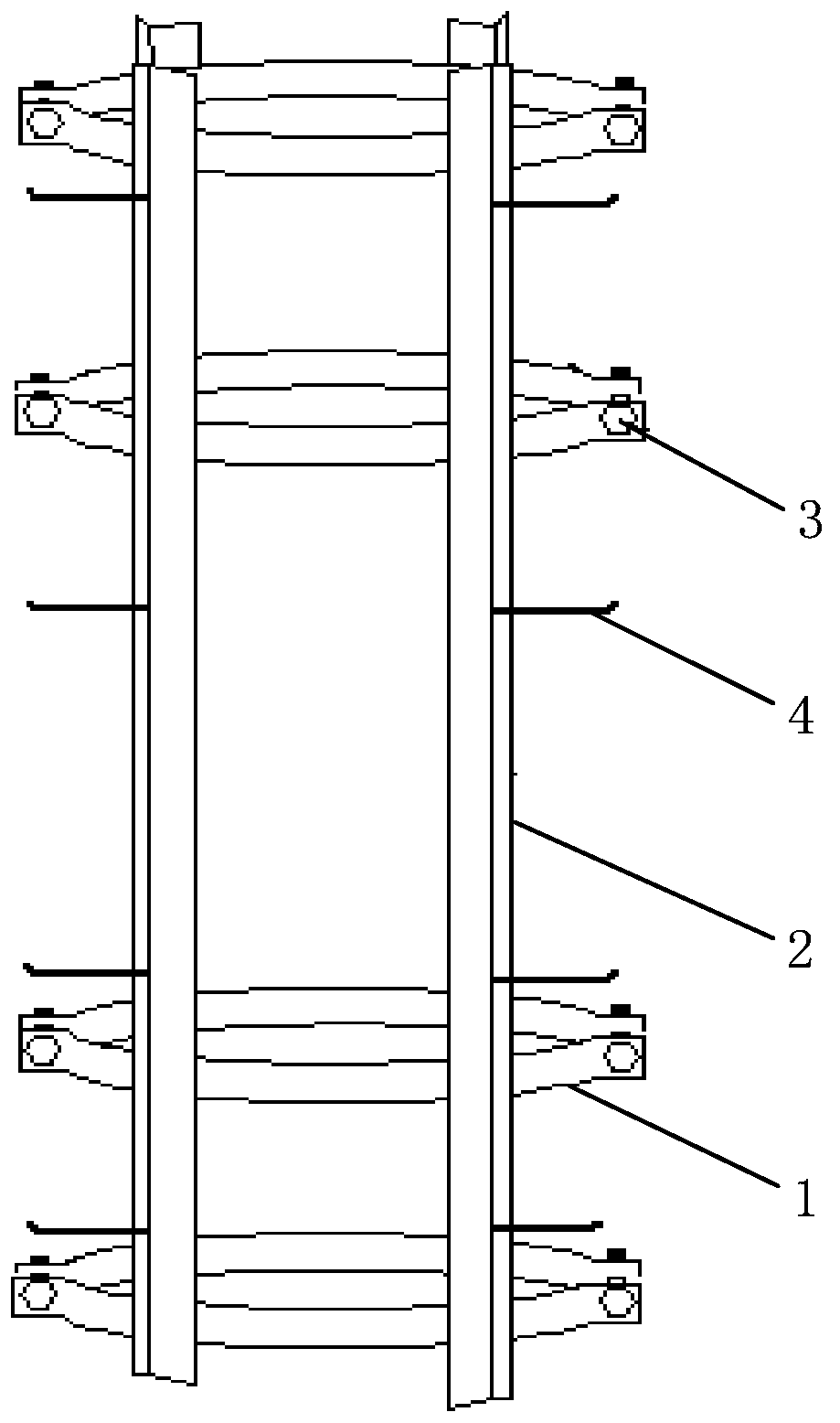

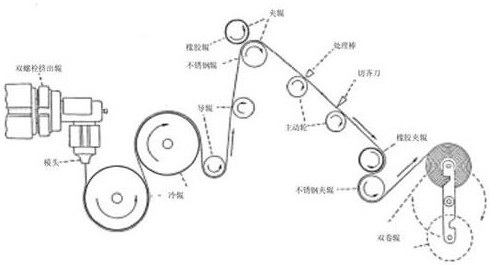

Electro-optic compound cable for towing and manufacturing method thereof

ActiveCN101714425AReasonable designCompact structureCommunication cablesFibre mechanical structuresPolyesterSilver plate

The invention relates to an electro-optic compound cable for towing, which is an electro-optic compound cable capable of retracting and releasing repeatedly in special occasions, and used for transmitting optical signals and electrical signals. The cable core is formed by twisting high temperature silver-plated leads and optical fiber, and is protected by spiral metal hose at outside, and polyurethane material is extruded outside the steel tube. The cable is composed of a plurality of silver-plated leads, tight tube optical fiber, polyester belting, a spiral stainless steel hose, an aramid fiber twisted layer and a polyurethane jacket; the tight tube optical fiber and the silver-plated leads are twisted into the cable core in an S twisting form, the cable core is wrapped and fixed by the polyester belting, the spiral stainless steel hose is arranged outside the polyester belting, the aramid fiber twisted layer is arranged outside the spiral stainless steel hose, and the polyurethane jacket is extruded outside the aramid fiber twisted layer.

Owner:ZHONGTIAN BROADBAND TECH +1

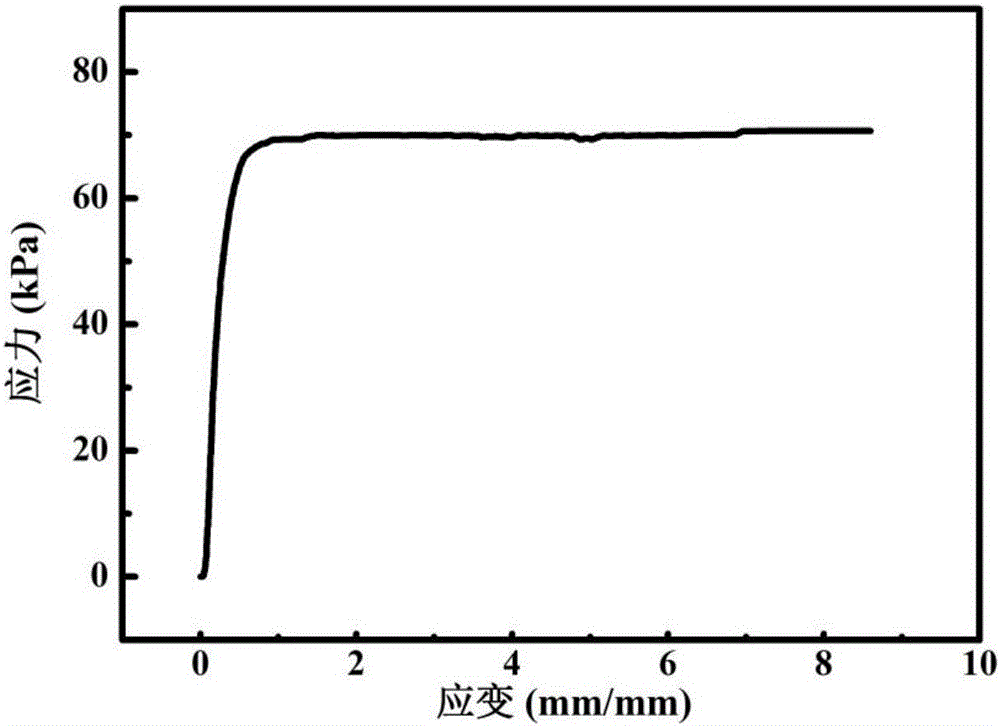

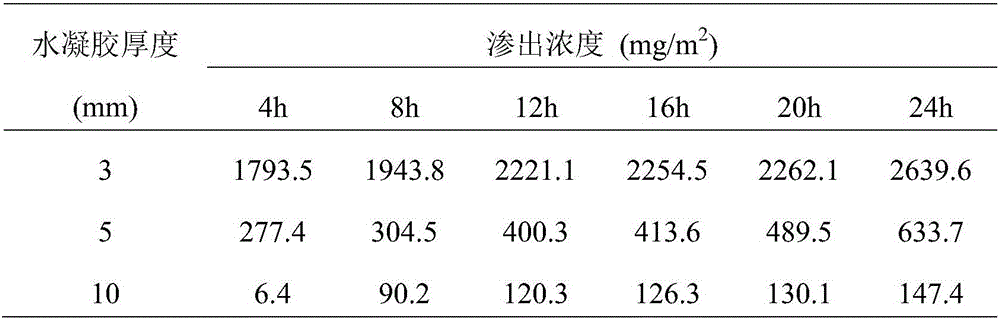

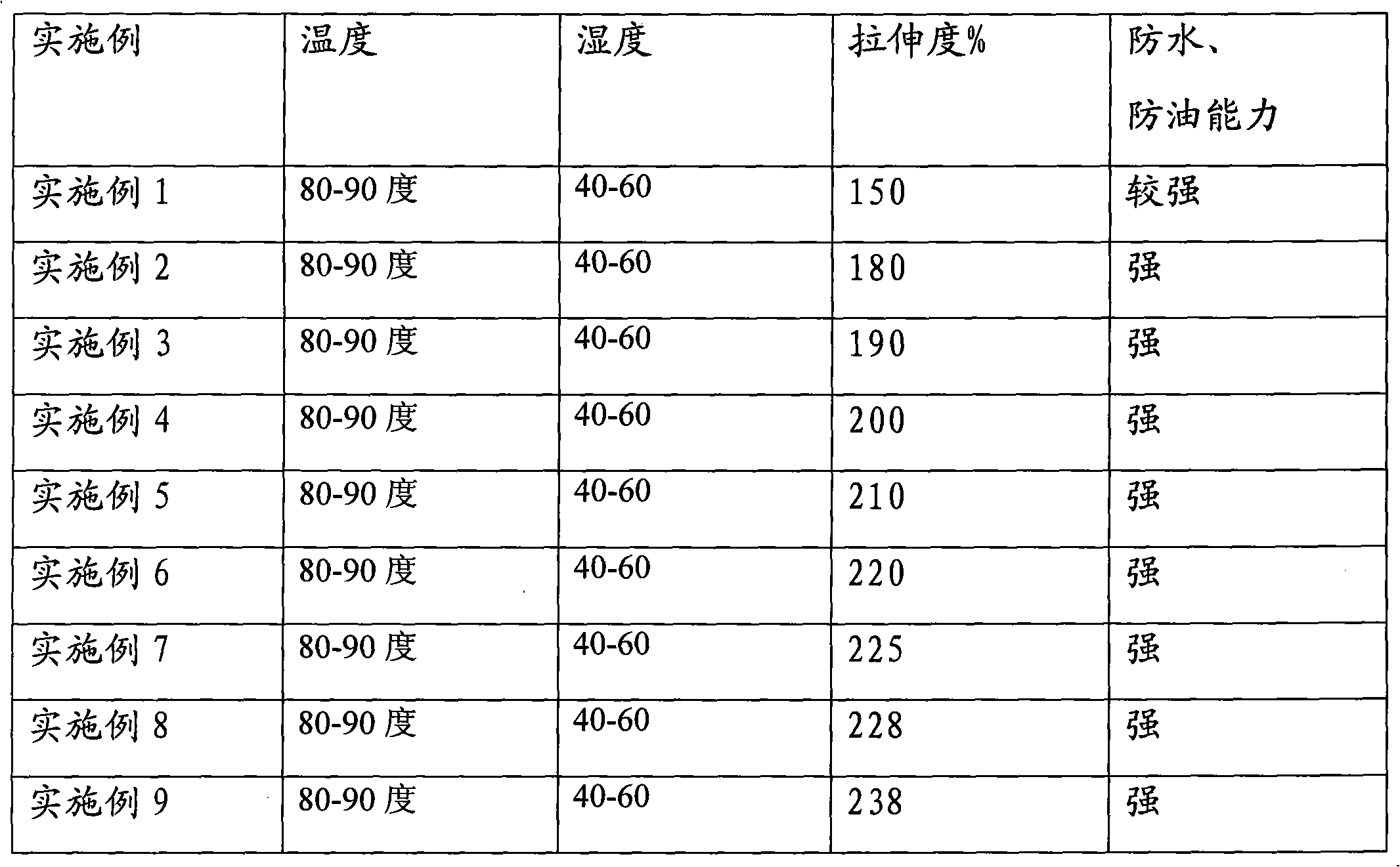

Toughened polyvinyl alcohol composite hydrogel and application thereof

InactiveCN105885064AStrong tensile propertiesBlock or at least delay the diffusion of volatilePVA - Polyvinyl alcoholBoron

The invention provides toughened polyvinyl alcohol composite hydrogel and an application thereof. The dual-component composite hydrogel is prepared from polyvinyl alcohol, a toughening linear macromolecular chain and a boron compound. During application, the two components in the same volume are put in two liquid storage containers of a dual-component liquid spray gun respectively and are sprayed by the spray gun to cover surfaces of dangerous chemicals, the two components react rapidly, the hydrogel is generated, and volatilization and diffusion of the dangerous chemicals are stopped. The toughened polyvinyl alcohol composite hydrogel has the characteristics that the gelation speed is high, the tensile property is high, the hydrogel is not prone to fracture and the like.

Owner:BEIJING UNIV OF CHEM TECH

Manufacture method of drum paper of loudspeaker

ActiveCN106930134AImprove clarityIncrease thicknessElectrical transducersWater-repelling agents additionMiddle frequencyLacquer

The invention discloses a manufacture method of drum paper of a loudspeaker, pertaining to the technical field of electroacoustic products. The method comprises the following steps: 1) pulping; 2) batching; 3) papermaking; 4) neck strengthening; 5) spraying varnish; 6) spraying glue or throwing glue; 7) cutting material; 8) forming; 9) applying edge glue; 10) attaching and reinforcing. The manufacture method of drum paper of the loudspeaker has the following beneficial effects: physical performance such as filling power, damping performance, light weightness and hardness and softness of the drum paper can be elevated so that the loudspeaker utilizing the drum paper can obtain good sound effect; sounds become softer and gentle so that comfortable and natural sounds that do not arouse fatigue can be obtained; meanwhile, pulp used by the drum paper has better clarity of the low-frequency and middle-frequency sound quality; toughness is improved; and the distortion rate is lower.

Owner:广西玉林市禹力音响配件有限公司

Preparation method of antibacterial repairing type medical non-woven fabric

InactiveCN107364195AHas antibacterial and deodorizing functionsAdhesiveLaminationLamination apparatusSterile waterWound scar

The invention discloses a preparation method of an antibacterial repairing type medical non-woven fabric. The preparation method is characterized by including: (1) opening: cleaning blend fibers in bacteria-free water for 2-3 times, and heating for opening; (2) combing to form a net: oscillating the blend fibers by ultrasonic waves with frequencies of 40 kHz and 25kHz, and settling to obtain a blend fiber net; (3) atomized water spraying: using pressurized atomized water to spray the front side and the reverse side of the blend fiber net; (4) drying: drying the blend fiber net in a low temperature after being sprayed by the atomized water; (5) preparing a bamboo fiber layer: preparing the dried blend fiber net into a bamboo fiber net layer according to the steps from (1) to (4); laminating by heat sealing: overlaying a tea fiber net layer with the bamboo fiber net layer, and adding medicament powder prior to laminating. The preparation method has the advantages that the prepared antibacterial repairing type medical non-woven fabric is uniform in thickness, high in stretchability, long in sterilizing effect lasting time and capable of healing a wound quickly and removing wound scars after being used.

Owner:JIESHOU SHUANGXIN TEXTILE

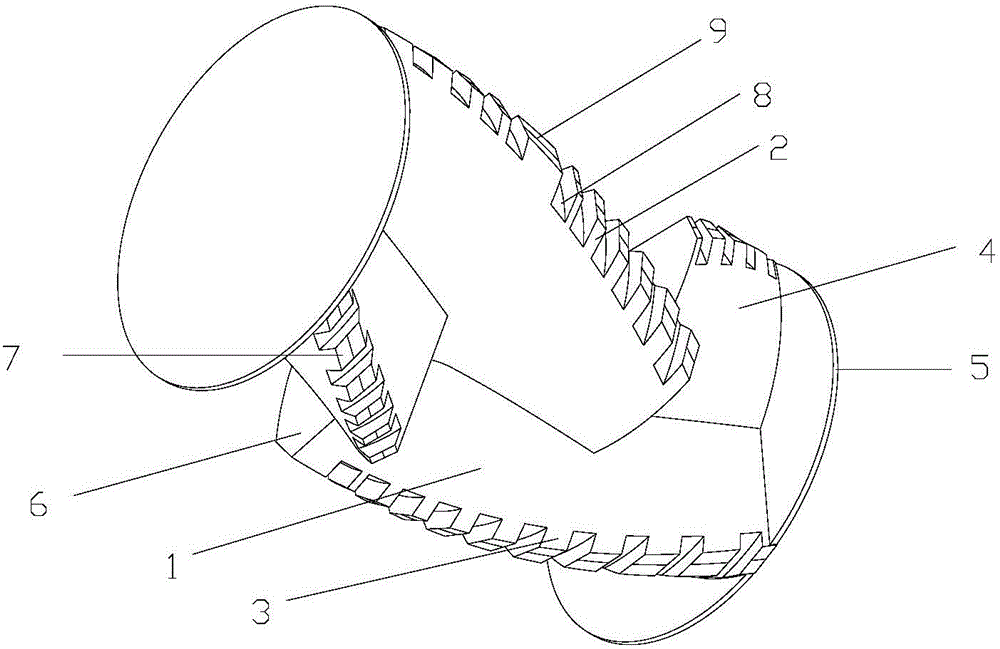

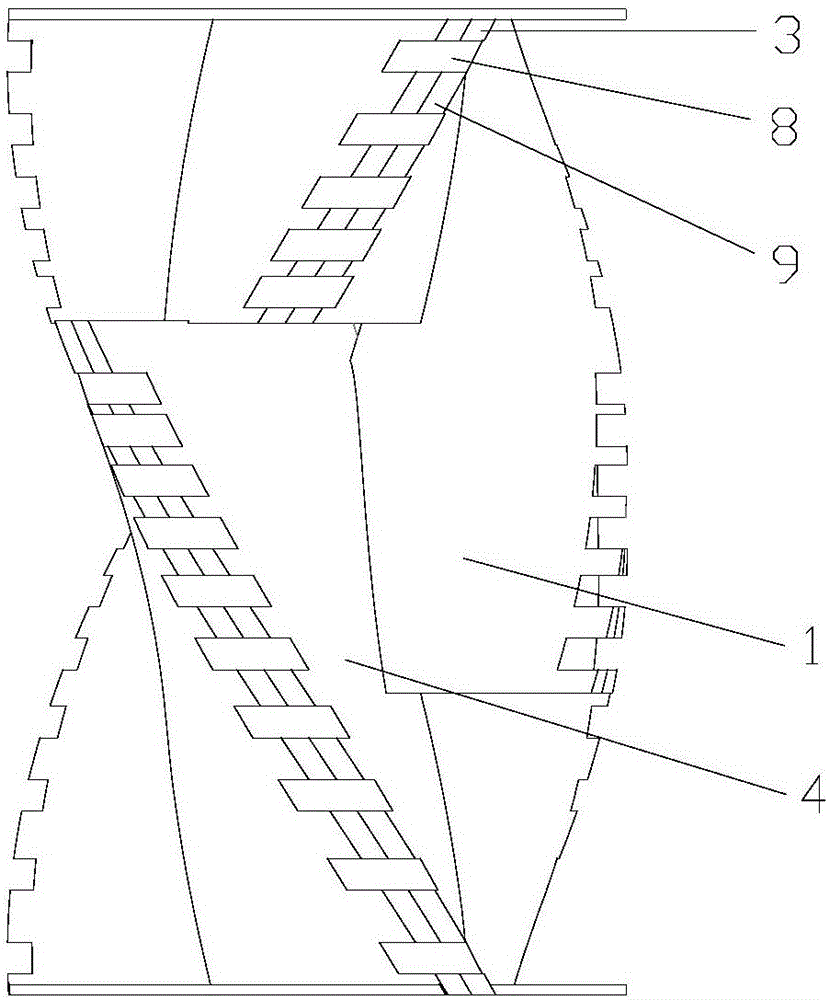

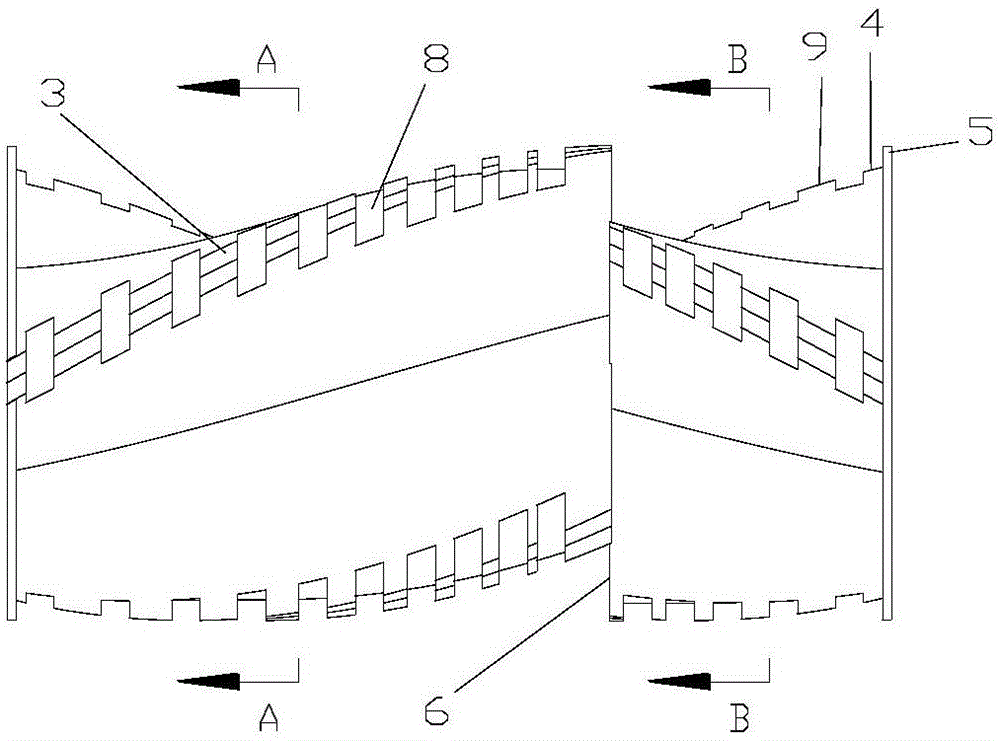

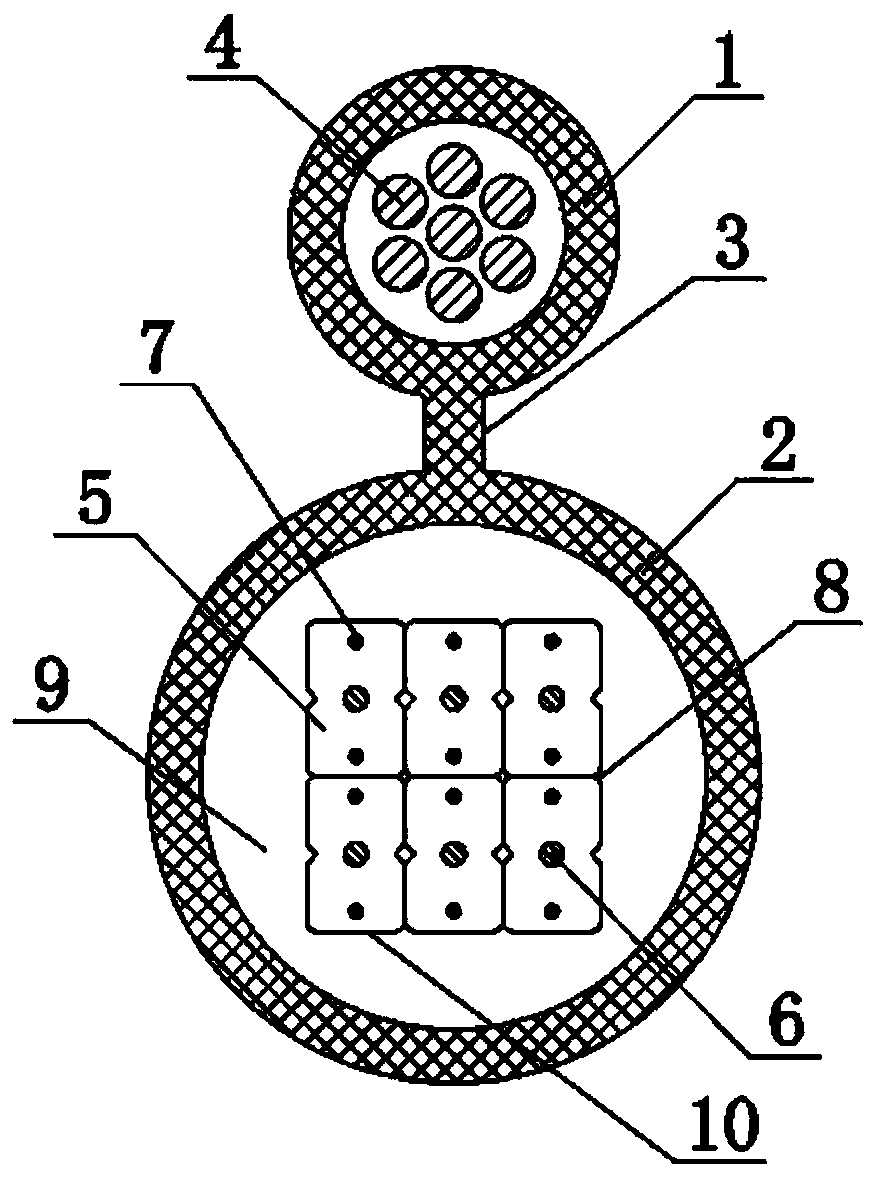

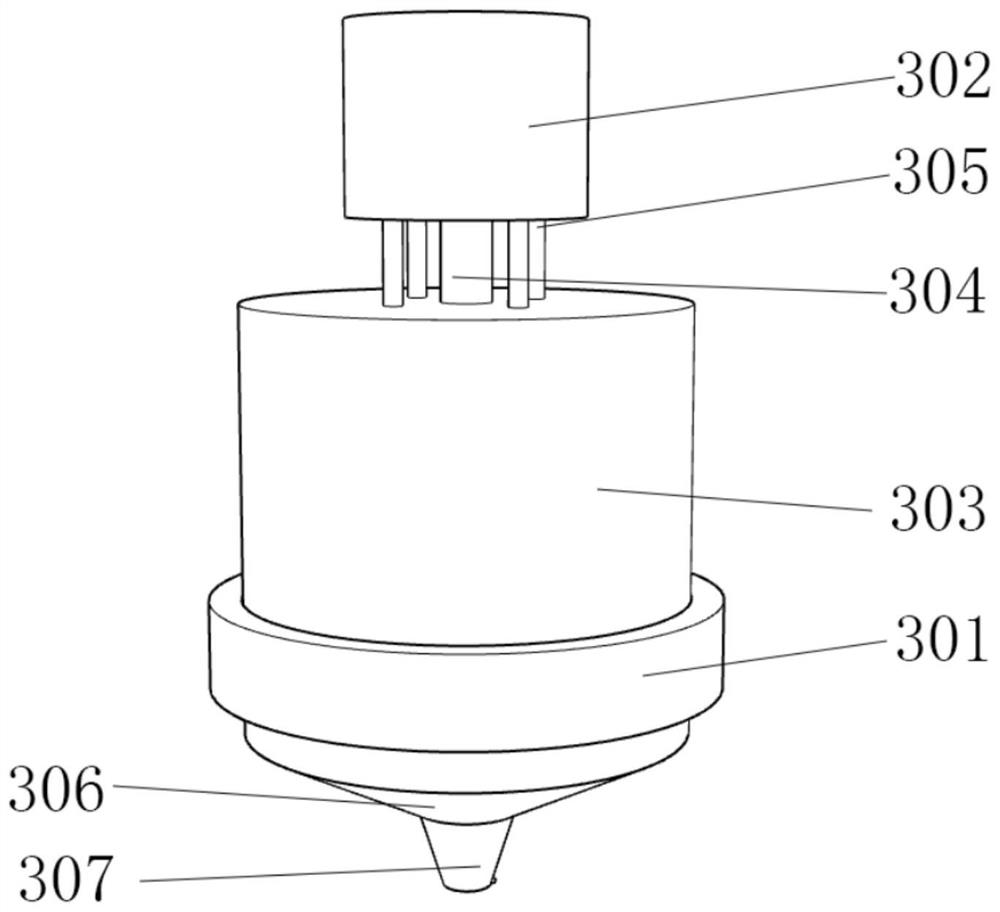

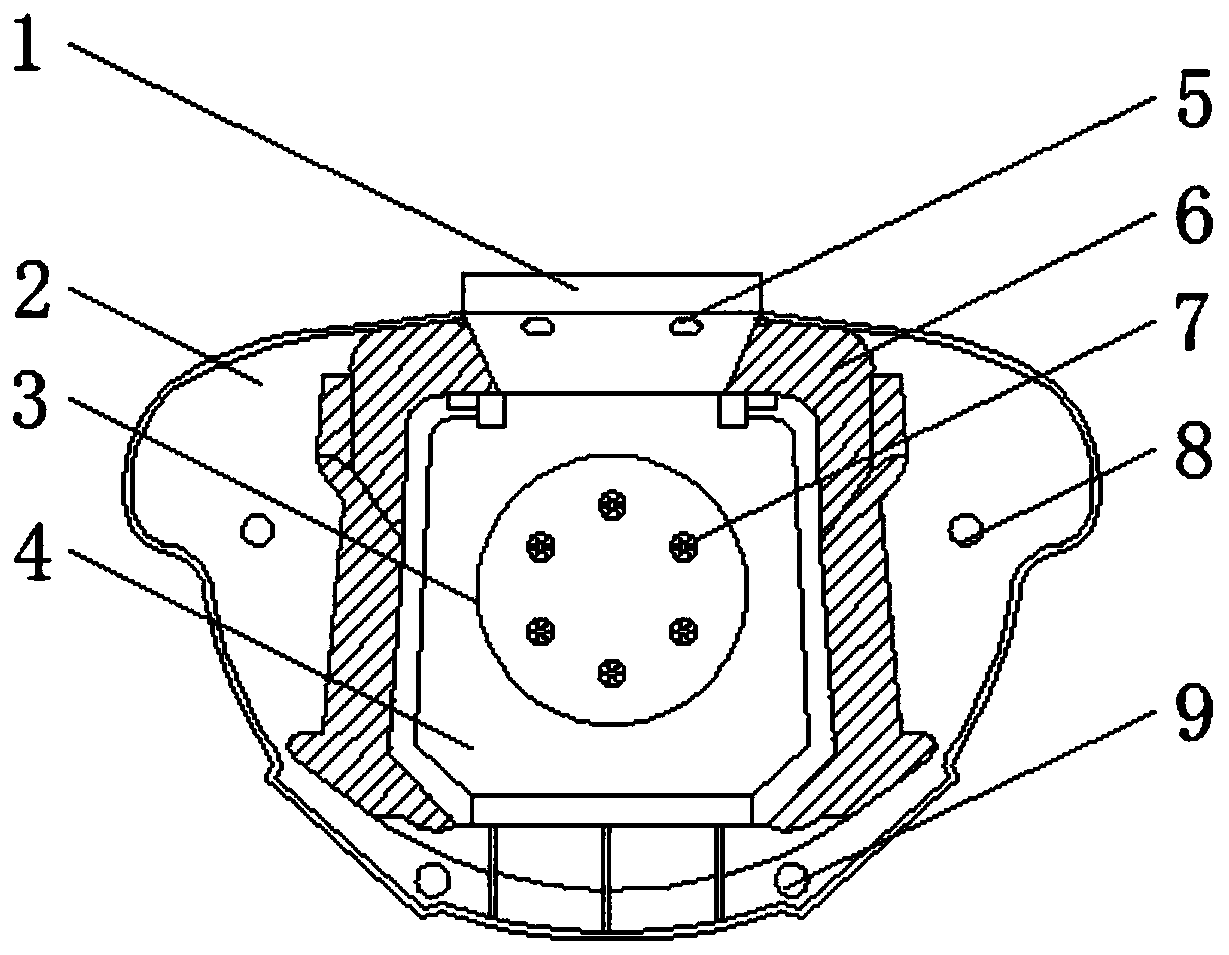

Six-ridge serrated dynamic variable-gap internal mixer rotor

The invention discloses a six-ridge serrated dynamic variable-gap internal mixer rotor which comprises a rotor body. Six protruded ridges are arranged on the rotor body, include three long ridges and three short ridges, spirally extend from two ends of the rotor body to the middle of the rotor body and comprise starting ends and finish ends; a plurality of tooth spaces are respectively arranged on ridge tops of the protruded ridges, the difference of the widths of the tooth spaces on each protruded ridge keeps unchanged in the direction from the starting end to the finish end of the protruded ridge, and the distances among the tooth spaces on each protruded ridge are gradually shortened in the direction from the starting end to the finish end of the protruded ridge. The six-ridge serrated dynamic variable-gap internal mixer rotor has the advantages that the tooth spaces are additionally arranged at the protruded ridges of the six-ridge serrated dynamic variable-gap internal mixer rotor, accordingly, peripheral flowing of rubber materials can be changed, and the six-ridge serrated dynamic variable-gap internal mixer rotor is favorable for distributing and dispersing various fillers and compounding ingredients; the quantities and the distribution density of the tooth spaces are increased along with increase of the peripheral flowing speeds of the rubber materials, accordingly, effects of masticating the lump-shaped rubber materials among the ridges can be enhanced, the rubber materials can flow in internal mixing chambers chaotically, and the rubber mastication quality and the rubber mastication efficiency can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

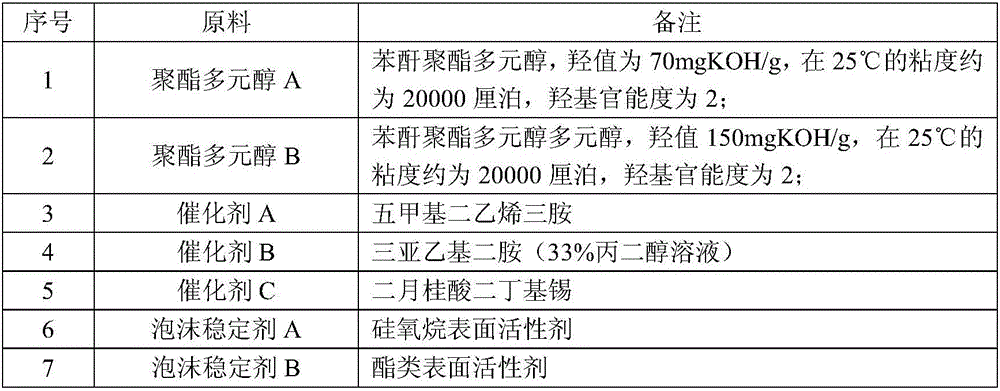

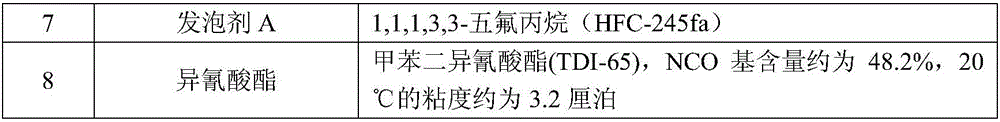

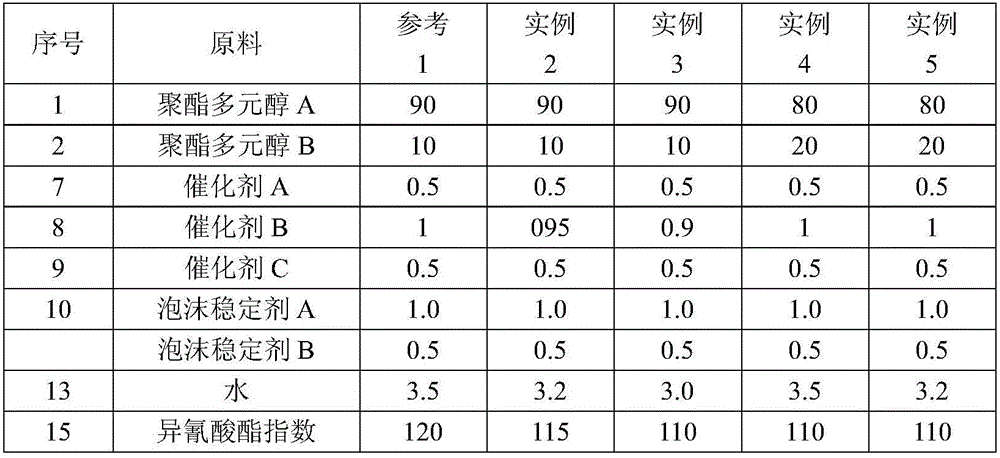

Polyester type reticular polyurethane soft foamed plastic and preparation method thereof

The invention discloses a polyester type reticular polyurethane soft foamed plastic and a preparation method thereof. The polyurethane soft foamed plastic is generated through the following steps of by using at least one polyester polyol as a raw material, enabling the polyester polyol and isocyanate components to be subjected to mixing, foaming and polymerization under the action of a catalyst, a foaming agent and a foam stabilizing agent to obtain polyurethane soft foamed plastic, and performing reticular treatment so as to obtain reticulated foams of which the open porosity is 99% or above. The special properties of being oil-proof, waterproof, abrasion-proof, corrosion-resistant, high-temperature-resistant, stretching-resistant and the like of polyester sponge are used, and particularly the characteristics that foam holes are uniform and the glossiness is good are used; through reticulated treatment, the reticulated foams which are uniform in holes and smooth in foam hole network are obtained. A high-temperature-resistant porous reticulated ceramic fired by the reticulated foams can be used as filtering materials in metallurgy trade, and is good in durability and economical efficiency. Compared with other products, the high-temperature-resistant porous reticulated ceramic particularly has inapproachable advantages.

Owner:JIANGSU LVYUAN NEW MATERIALS

Manufacturing method of super bass drum paper

ActiveCN106686517AImprove bass qualityImprove bulkElectrical transducersNeck partsPulp and paper industry

The invention discloses a manufacturing method of super bass drum paper and belongs to the technical field of electroacoustic products. The manufacturing method includes the steps of firstly, beating; secondly, making paper; thirdly, reinforcing neck parts; fourthly, spraying varnish; fifthly, spraying or tossing glue; sixthly, cutting; seventhly, forming; eighthly, applying glue to edges; ninthly, adhering; tenthly, sewing and reinforcing. The manufacturing method has the advantages that the bass quality of the super bass drum paper is increased, distortion rate is lowered to a large degree, the physical performance such as filling power, damping performance, lightweight performance and stiffness-flexibility combination of the obtained drum paper is well improved, a loudspeaker using the drum paper can have a good sound effect, and sounds are soft, gentle and elegant, relaxing, natural and less prone to fatigue causing.

Owner:广西玉林市禹力音响配件有限公司

High-efficiency corrosion resistant pre-mixed mortar

The invention relates to a pre-mixed mortar material for buildings and particularly relates to high-efficiency corrosion resistant pre-mixed mortar. The mortar is prepared by mixing the following ingredients in percentages by weight: 5-20% of river sand, 10-30% of manufactured sand, 10-20% of flyash, 10-20% of granulated blast-furnace slag powder, 1-2% of polycarboxylic acid, 1-2% of sodium gluconate, 5-15% of cement, 5-15% of redispersible powder, 5-10% of kaolin and 5-10% of an electrolytic manganese slag waste. By using the pre-mixed mortar prepared at the ratio, the prepared concrete has the characteristics of being hard, corrosion-resistant and low in cost, and has wide applicability.

Owner:中山市群发建筑材料有限公司

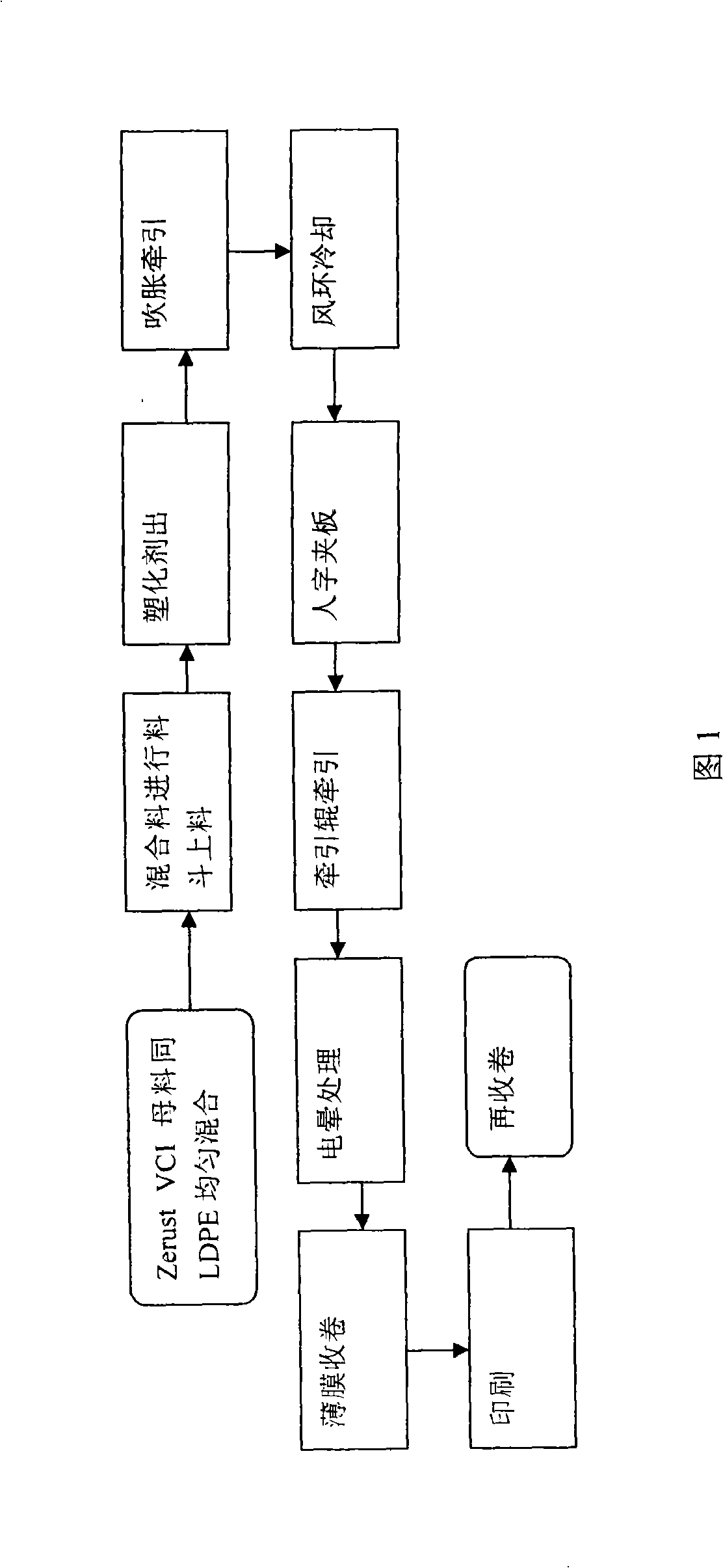

Method for processing anti-rust film

InactiveCN101279505AMeet environmental protection requirementsImprove cleanlinessFlat articlesGramProcessing cost

The invention relates to a method for processing an antirust film., In weight ratio, a master batch consisting of a plurality of rust inhibitors, an oxygen scavenger and a propellant accounts for 3 percent to 5 percent, other materials consisting of polyethylene resin LDPE accounts for 95 percent to 97 percent and the polyethylene resin LDPE can not contain other additives; according to requirements, an ordinary melt index MI ranges from 3 grams per 10 minutes to 5 grams per 10 minutes; the content of the silicon contained in a slip agent must be less than 1200 ppm and the mixed raw material is extruded by a plastic extruder. the antirust and package can be integrated as one for the antirust film product, which has the following advantages and is characterized in that: the antirust film product meets the requirements for human body and environmental protection; the product can be directly recycled, can be simply and conveniently used, saves labors and increases the efficiency, and has strong antirust capability, has a shipping protection which can reach 2 years and has a warehousing protection which can reach 5 years usually. After receiving the parts which are protected by the packaging of the product, clients can directly install the parts on line without requiring the traditional procedures of re-cleaning and drying, thus greatly reducing the processing cost, eliminating the strict requirement for environmental protection in the workshop is kept clean and dry without needing the strict environmental processing requirements in the traditional process of cleaning and discharging the antirust oil and keeping the environment in the workshop clean and dry.

Owner:TIANJIN ZERUST ANTI CORROSION TECH

Anti-oxidation and environment-friendly protecting film and preparation process thereof

InactiveCN106147635AEasy to degradeEasy to recycleFilm/foil adhesivesSynthetic resin layered productsLow-density polyethyleneTectorial membrane

The invention relates to the technical field of film adhesive tape materials, in particular to an anti-oxidation and environment-friendly protecting film and a preparation process thereof. The protecting film adopts a double-layer structure, wherein the surface layer of the protecting film is an LDPE (low-density polyethylene) film, the bottom layer of the protecting film is a VMPE (vacuum metallized polyethylene) film, a double-component ester-soluble compound adhesive is applied between the surface layer and the bottom layer of the protecting film, and a waterborne acrylic ester pressure-sensitive adhesive is applied to the bottom surface of the bottom layer of the protecting film. The advantages that a polyethylene material is easy to degrade and recycle are utilized, the production cost is greatly reduced, the resource waste is reduced, the environment-friendly protecting film is obtained, and the demands for sustainable development in the market are met.

Owner:常熟市新明宇新材料科技有限公司

Heat-conducting low-temperature co-fired ceramic material and preparation method thereof

The invention discloses a heat-conducting low-temperature co-fired ceramic material and a preparation method thereof, wherein the material comprises, by weight, 100 parts of Bi-based glass, 80-150 parts of aluminum oxide ceramic powder and less than or equal to 3 parts of carbide, wherein the particle size of the aluminum oxide ceramic powder is 1-2 [mu]m. The method comprises: mixing bismuth trioxide, boron oxide, silicon oxide, zinc oxide and aluminum oxide, melting, and carrying out water-cooling quenching; carrying out ball milling on obtained Bi-based glass residue into powder, and mixingwith aluminum oxide ceramic powder; sequentially carrying out joint ball milling on the obtained mixed powder, a solvent, a dispersing agent, a binding agent, a plasticizer and a homogenizing agent;and carrying out casting molding on the obtained stable and uniform slurry in a mold, drying, sequentially placing the obtained raw ceramic sheet at 300-600 DEG C to remove organic additives, and carrying out sintering molding at 800-950 DEG C to obtain the target product. According to the invention, the heat-conducting low-temperature co-fired ceramic material has characteristics of significantlyincreased heat-conducting property and significantly improved dielectric property, and is easily, widely and commercially applied to the field of electronic packaging.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

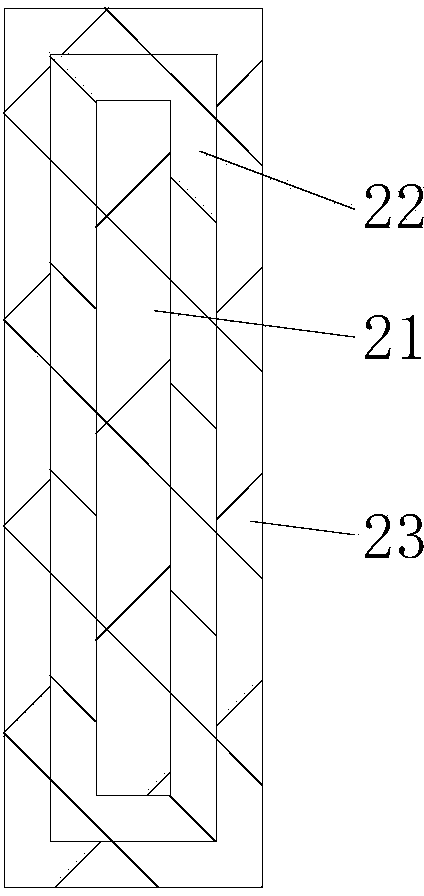

Butterfly optical cable

InactiveCN110389417AStrong tensile propertiesGood LayingFibre mechanical structuresEngineeringElectrical and Electronics engineering

Owner:武汉瑞联光通信技术有限公司

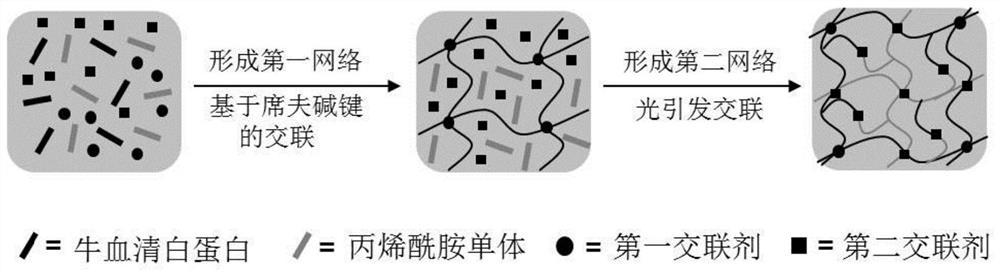

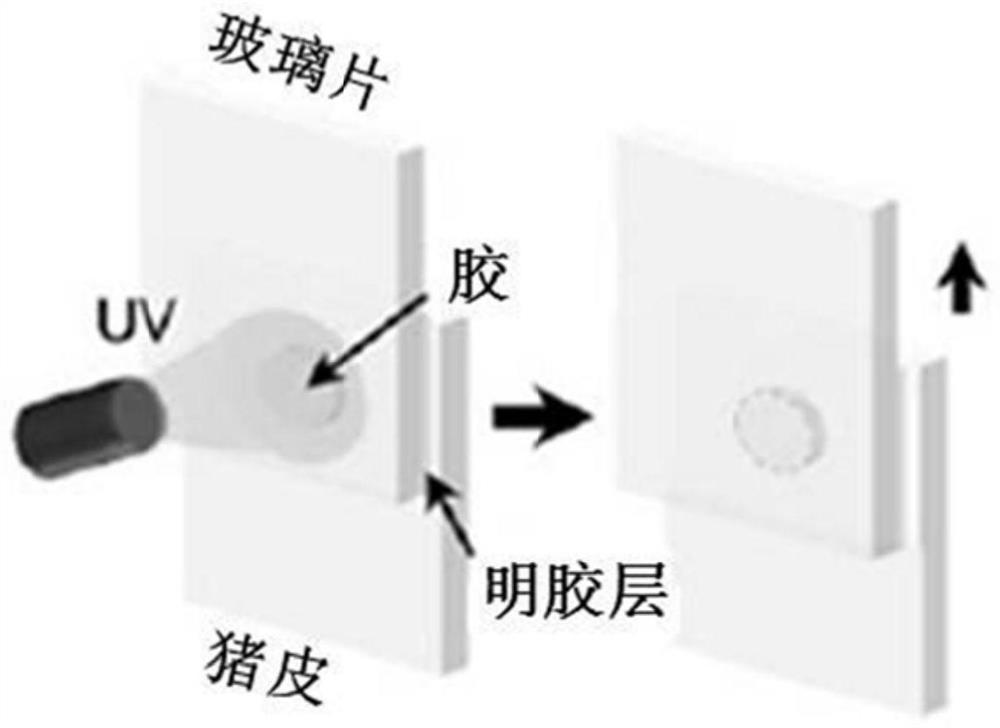

Albumin adhesive and preparation method thereof

ActiveCN111892907AHigh bond strengthStrong Tensile PropertiesNon-macromolecular adhesive additivesProtein adhesivesBlood serumPolymer chemistry

The invention provides an albumin adhesive and a preparation method thereof. The albumin adhesive comprises bovine serum albumin, an acrylamide monomer, a first cross-linking agent and a second cross-linking agent. The strength of the bonding between the dual-network cross-linked albumin adhesive disclosed by the invention and tissues can be enhanced; the albumin adhesive has relatively strong elasticity and mechanical tensile property, and is controllable in forming process.

Owner:GUANGDONG PROV MEDICAL INSTR INST

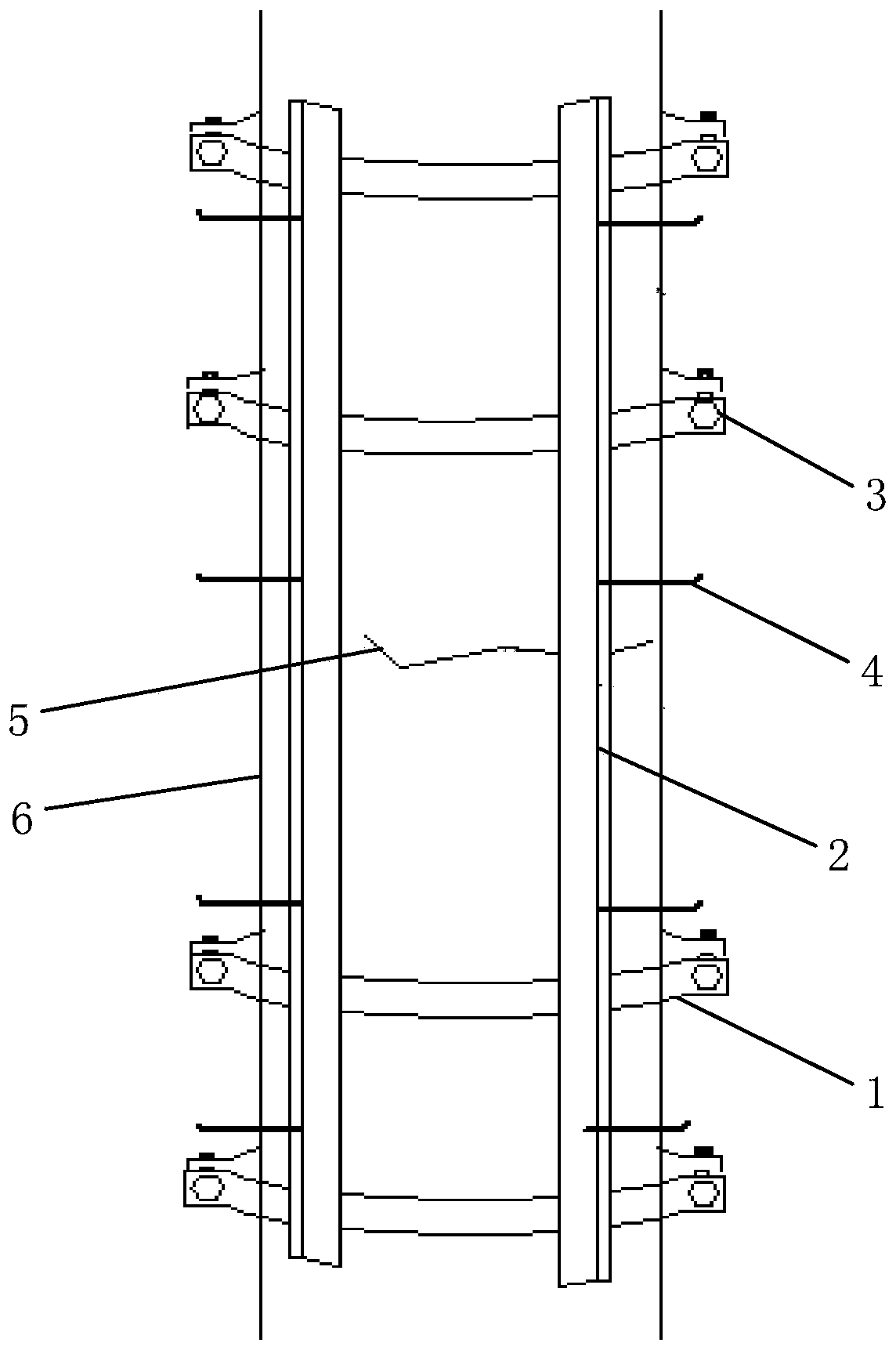

Cement electricity pole crack defect processing device and method

InactiveCN109881965AElimination of crack defectsEliminate crack defectsBuilding repairsTowersFastenerElectricity

The invention discloses a cement electricity pole crack defect processing device and a method. The cement electricity pole crack defect processing device comprises a plurality of flat iron hoops, a plurality of angle iron and fastening bolts, the multiple flat iron hoops are arranged at cement electricity pole cracks, and the flat iron hoops are fixedly connected through the fastening bolts; and the angle iron and the flat iron hoops are perpendicularly arranegd, and the outer sides of any side walls of the angle iron are welded to the outer sides of the flat iron hoops. According to the cement electricity pole crack defect processing device, the flat iron hoops are used as fastening pieces, the angle iron are used as longitudinal forced supporting pieces, and the cross welding of the angle iron and the outer sides of the flat iron hoops is firm. By adopting the processing device and method, cement electricity pole crack defects can be controlled without outage, the risk of cement electricity pole breakage is removed, and the outage cost is reduced. In addition, the pole changing work can be replaced, the work risk is reduced, material costs and labor costs as required are far lower than the cost of a whole cement electricity pole changing, and the defect processing cost is greatly reduced.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

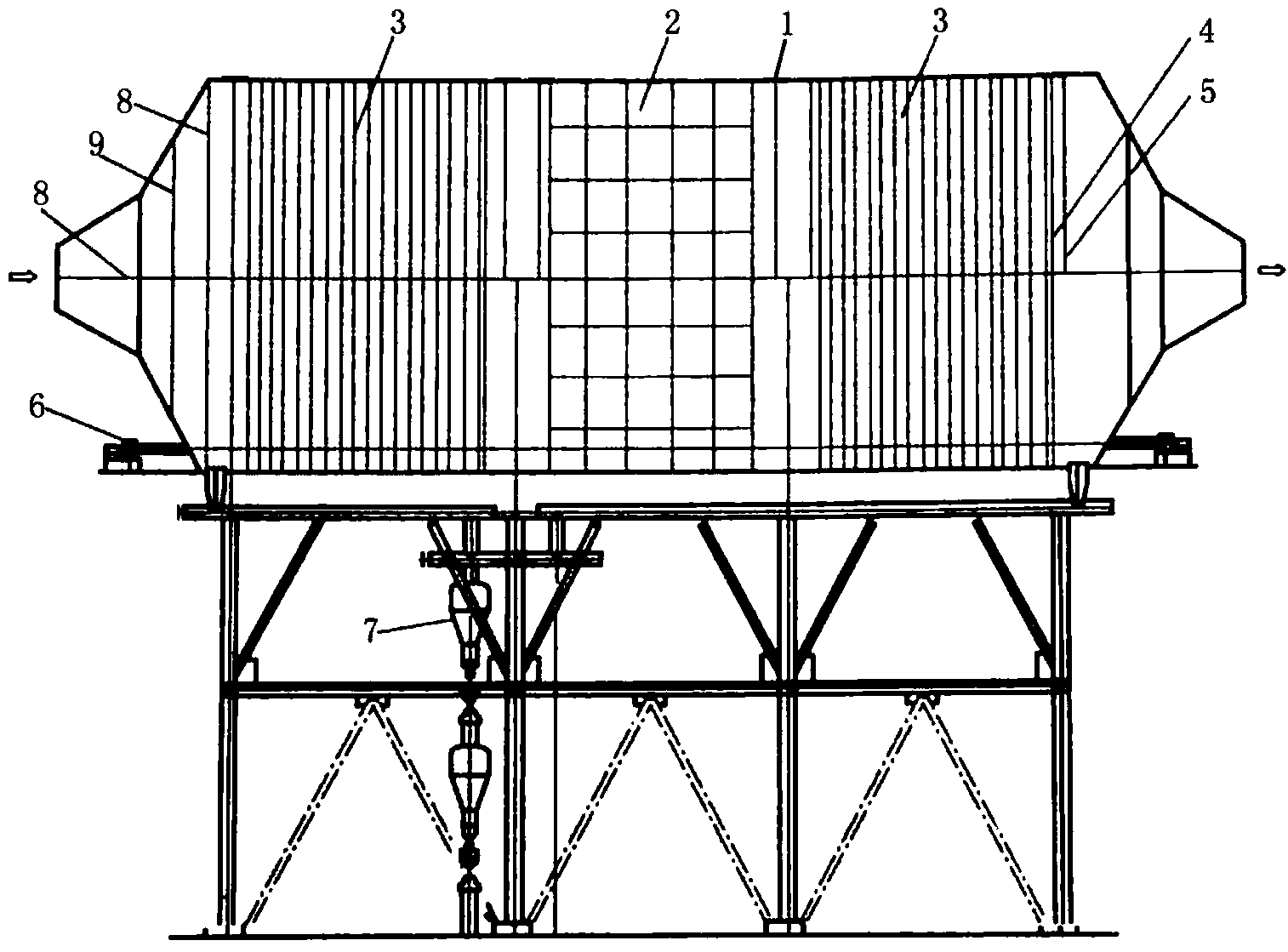

Dry type electrostatic dust collector

InactiveCN104368441AExtended service lifeStrong tensile propertiesExternal electric electrostatic seperatorElectrode constructionsFiberCarbon fibers

The invention discloses a dry type electrostatic dust collector. The dry type electrostatic dust collector comprises a shell body, wherein the shell body is internally provided with a discharging electrode and dust collection electrodes located at the two sides of the discharging electrode; the shell body is internally provided with a discharging electrode vibration device and a dust collection electrode vibration device, and is also internally provided with a spiral conveyor located under the dust collection electrodes and the discharging electrode; an ash collection cabin communicated with the inner cavity of the shell body is arranged on the outer side wall of the shell body; the discharging electrode is composed of a carbon steel layer, a carbon fiber glass fiber reinforced plastic layer and a carbon fiber membrane; the carbon steel layer is covered by the carbon fiber glass fiber reinforced plastic layer; and the carbon fiber glass fiber reinforced plastic layer is covered by the carbon fiber membrane. According to the dry type electrostatic dust collector, the corrosion resisting performance of the discharging electrode is good and the whole service life of the dry type electrostatic dust collector is ensured.

Owner:CHANGZHOU CHANGLONG INFORMATION TECH

Papermaking mixture and paper made of same

InactiveCN102031718AImprove waterproof performanceStrong oil resistanceSpecial paperReinforcing agents additionAluminium sulfatePapermaking

The invention provides a papermaking mixture which comprises the following components in percentage by weight: 2-40 glue water, 5-45 water-proofing agent, 5-25 dry strength agent, 10-20 aluminum sulfate and the balance of water. In addition, the invention also provides a piece of paper made of the papermaking mixture, which comprises the following components in percentage by weight: 10-35 papermaking mixture and 70-95 base paper. The paper made of the papermaking mixture not only can be waterproof and oil-proof, but also has large tensile strength.

Owner:邵建波

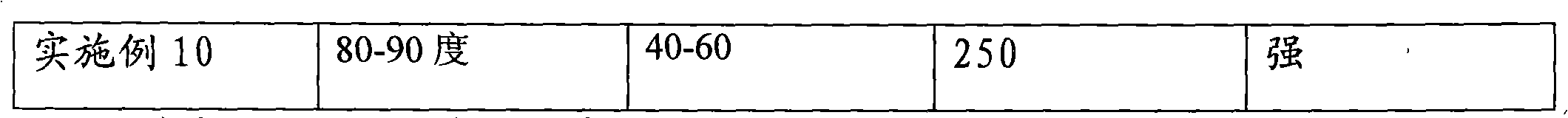

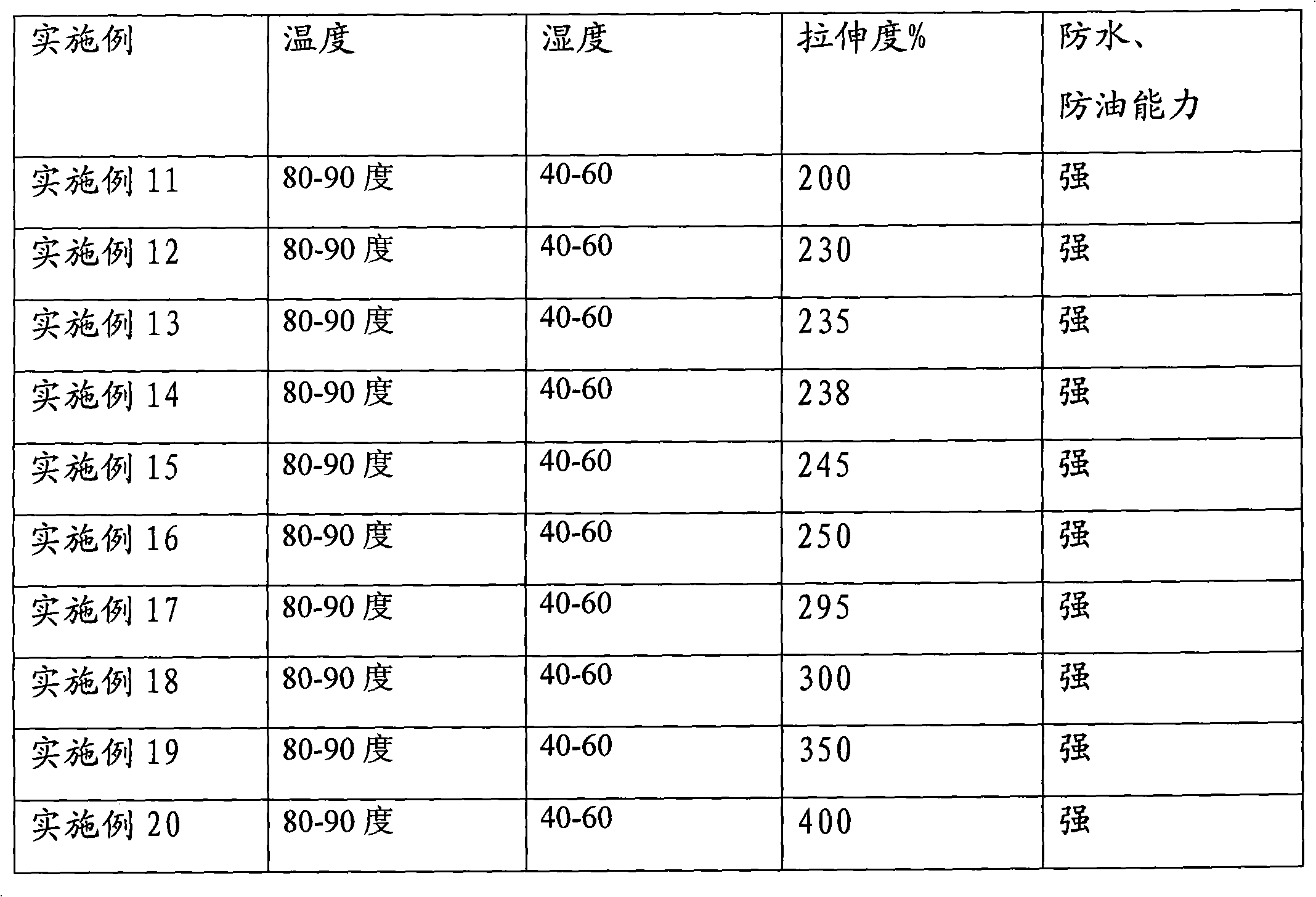

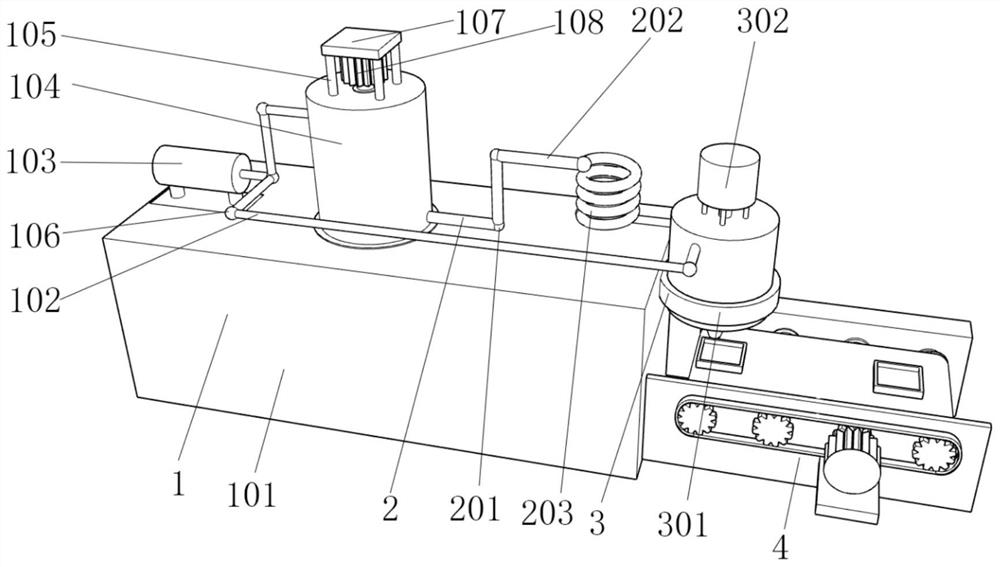

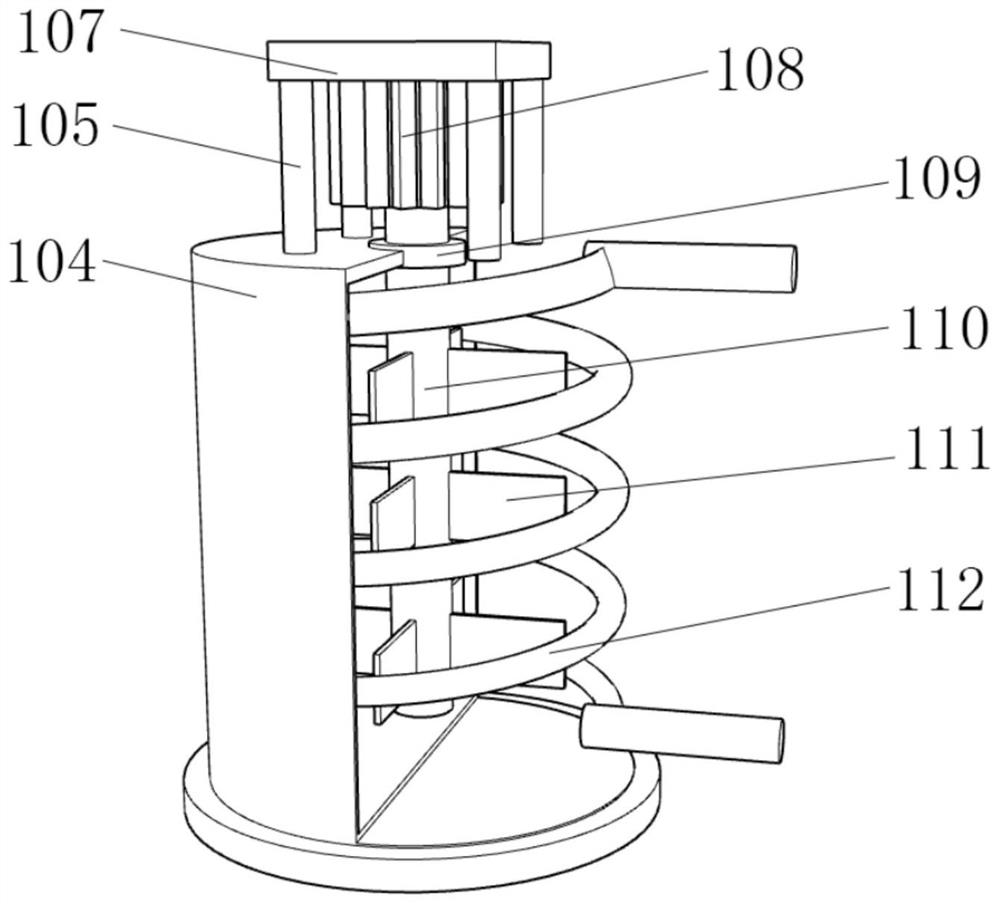

Special cylinder gasket for assault boat and production process of special cylinder gasket

PendingCN113997619AImprove efficiencyKeep tightLiquid surface applicatorsSealing arrangements for enginesProcess engineeringFan blade

The invention relates to the technical field of cylinder gasket sealing performance, and discloses a special cylinder gasket for an assault boat and a production process of the special cylinder gasket for the assault boat. The special cylinder gasket is characterized in that a primary processing mechanism comprises a fixed base, an air compressor is fixedly connected to one side of the top end of the fixed base, and a conveying pipeline is fixedly connected to the middle of one end of the air compressor. According to the invention, by arranging the fixed base, fixing of processing equipment is facilitated; by arranging the air compressor, generation of compressed air is facilitated; by arranging the conveying pipeline and the connecting body, transmission of the compressed air is facilitated; by arranging the first reaction cylinder, production and processing of raw materials are facilitated; by arranging the fixed plate and the supporting columns, the fixation of the motor is facilitated; by arranging the motor, the rotating shaft and the stirring fan blades, the motor can drive the rotating shaft and the stirring fan blades to rotate, so that the whole raw materials are thoroughly mixed, the processing efficiency is improved; and by arranging the heating pipe, the regulation and control of the temperature in the first-time reaction cylinder are facilitated.

Owner:浙江杭垫科技有限公司

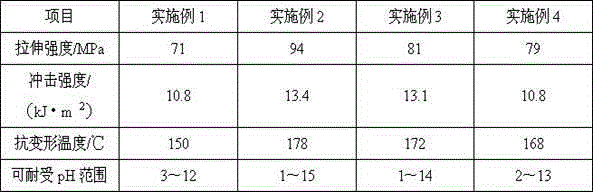

Corrosion-resistant film material and preparation method thereof

The invention discloses a corrosion-resistant film material and a preparation method thereof. A packaging material mainly comprises a carrier material, bonding resin and phenolic epoxy resin for a high-temperature adhesive, wherein the carrier material is prepared from the following raw materials in parts by weight: 2-13 parts of an ethylene-vinyl acetate copolymer, 2-13 parts of high polymer polypropylene and 1-14 parts of polysulfone; the fixed weight of the ethylene-vinyl acetate copolymer is required to be 20-35 g / m<2>, the fixed weight of high polymer polypropylene is required to be 15-25 g / m<2>, and the fixed weight of polysulfone is required to be 13-30 g / m<2>; the bonding resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for dipping, and the solid content of the resin is 41-52%. The corrosion-resistant film material has the characteristics of strong stretching capability, excellent weather resistance and moderate deformation temperature, can be resistant to strong acid, strong base and an organic solvent, and is convenient to use and simple to operate.

Owner:SUZHOU DINGLI PACKAGING

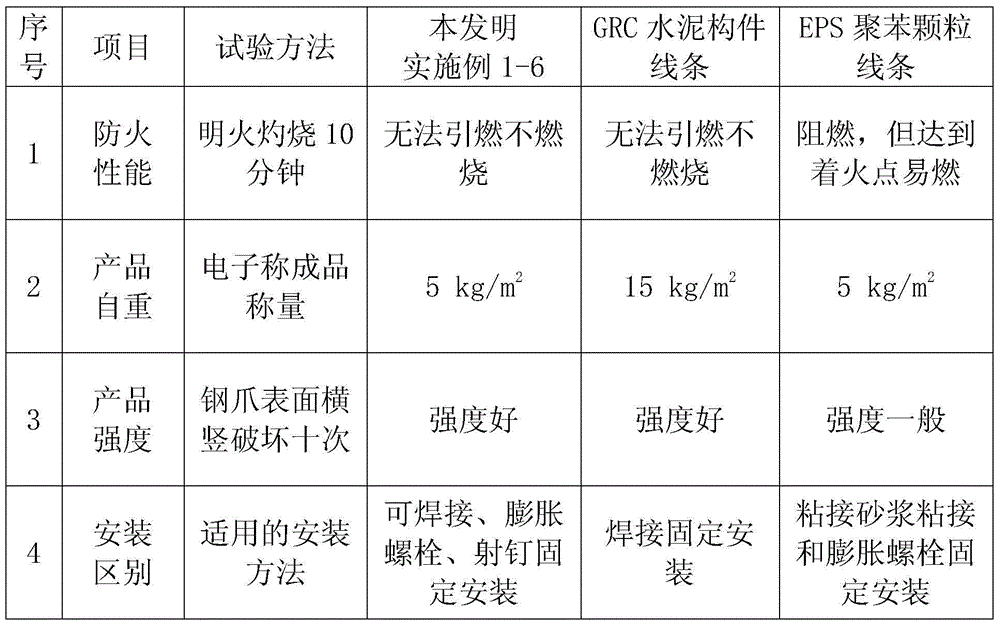

TGB cement polyphenyl line building material

InactiveCN105016658ATo achieve the perfect combinationNon-combustible safetyBuilding constructionsGlass fiberFire resistance

The invention provides a TGB cement polyphenyl line building material and a preparation method thereof. The TGB cement polyphenyl line building material comprises the following components by weight percent: 10-30% of 425# high-strength low-alkali cement, 50-70% of polyphenyl foam particles, 2-6% of fine sand, 2-6% of carborundum, 2-10% of hydrogel, 1-5% of phi6 welded reinforcement, 1-5% of phi4 skeleton reinforcement, 0.1-2% of fiber glass filament and 0.5-4% of special gelatine powder. The TGB cement polyphenyl line building material has light self weight, good fire resistance and strong strentchability, breaking resistance and crushing resistance, and is simple in preparation process, convenient to install and suitable for large-scale popularization and application.

Owner:陕西兴洋建筑工程有限责任公司

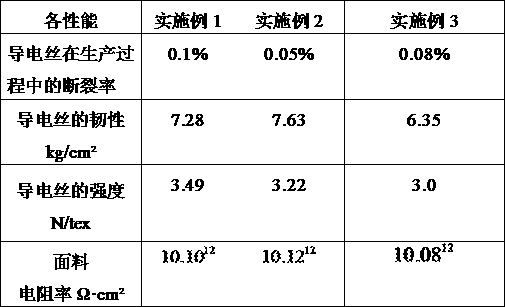

Double-sided high-strength antistatic fabric and production process

ActiveCN108930087AImprove toughnessStrong stretching abilitySynthetic resin layered productsLaminationPolyesterYarn

The invention provides a double-sided high-strength antistatic fabric. The fabric is formed by bonding two layers of fabric bodies. Each layer of fabric body is formed by weaving composite yarns, andthe fabric body is a plane three-way fabric. The composite yarn comprises a spun polyester thread and a conductive fiber winded out of the spun polyester thread in a loose manner. The spun polyester thread is a 5D-8D low-elasticity spun polyester thread. Grain size of the conductive fiber is 1.1(N / G)<1 / 2> / ZS. Cooperated with the production process provided by the invention, tenacity of the conductive fiber is relatively high, and the conductive fiber does not easily break. Production is convenient, fabric structure is meticulous, density is high, dust does not easily enter the fabric, the conductive fiber and a fabric base material combine tightly, a condition that conductive fiber drawing would not occur, and antistatic effect is lasting.

Owner:嘉兴市优泰纺织新材料有限公司

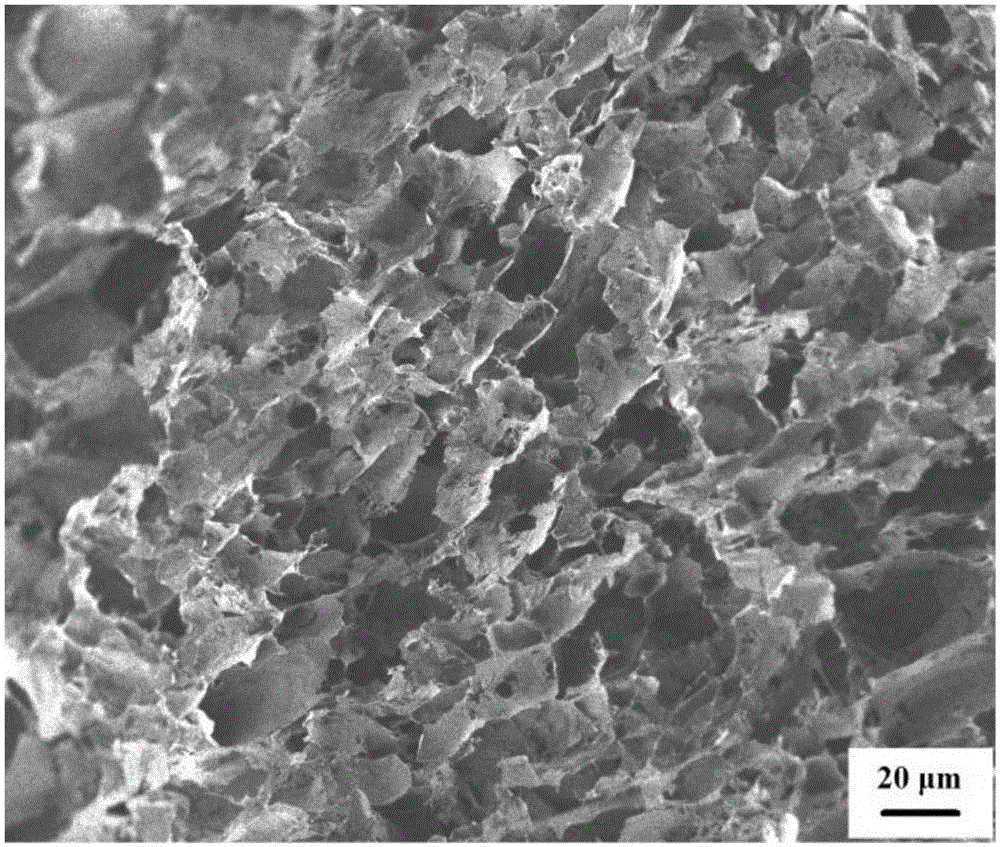

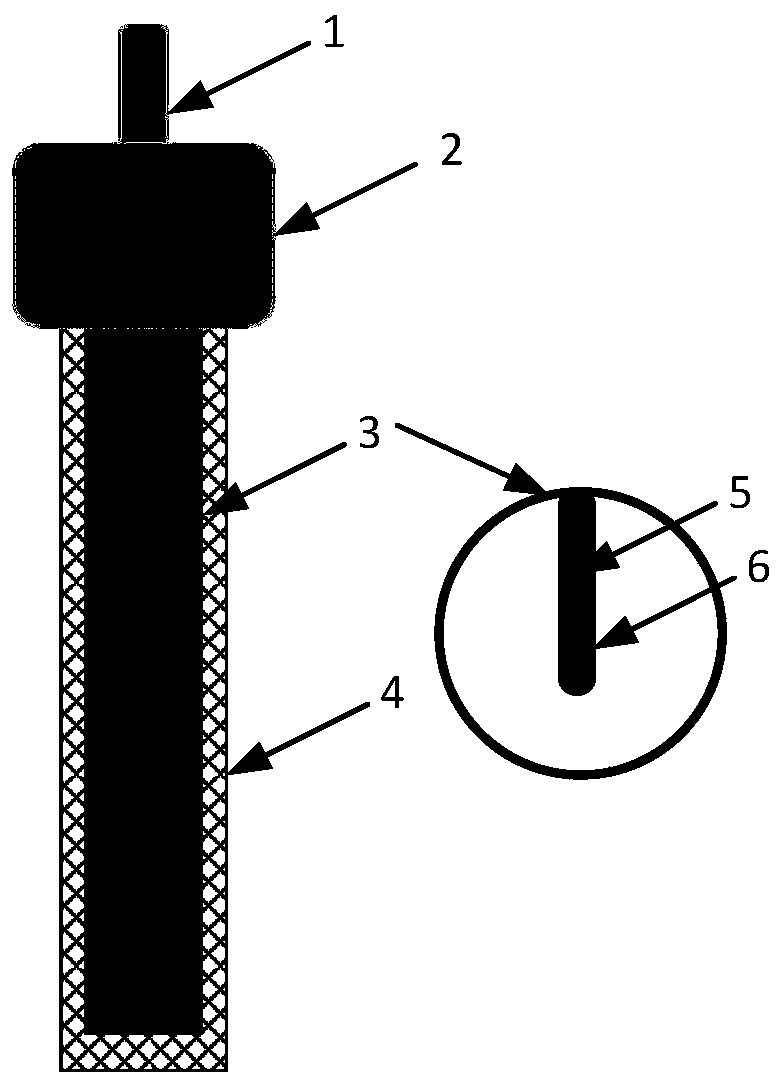

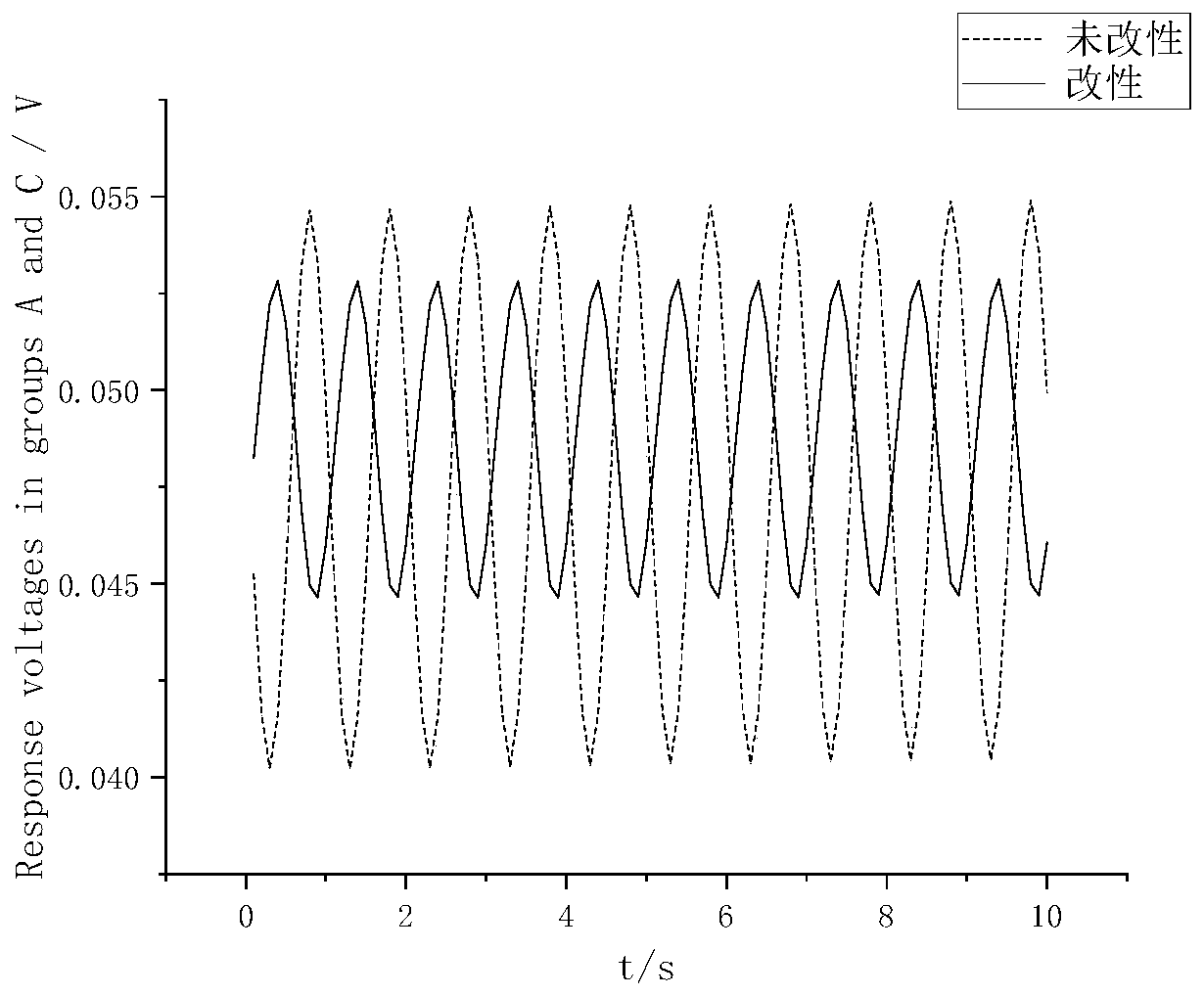

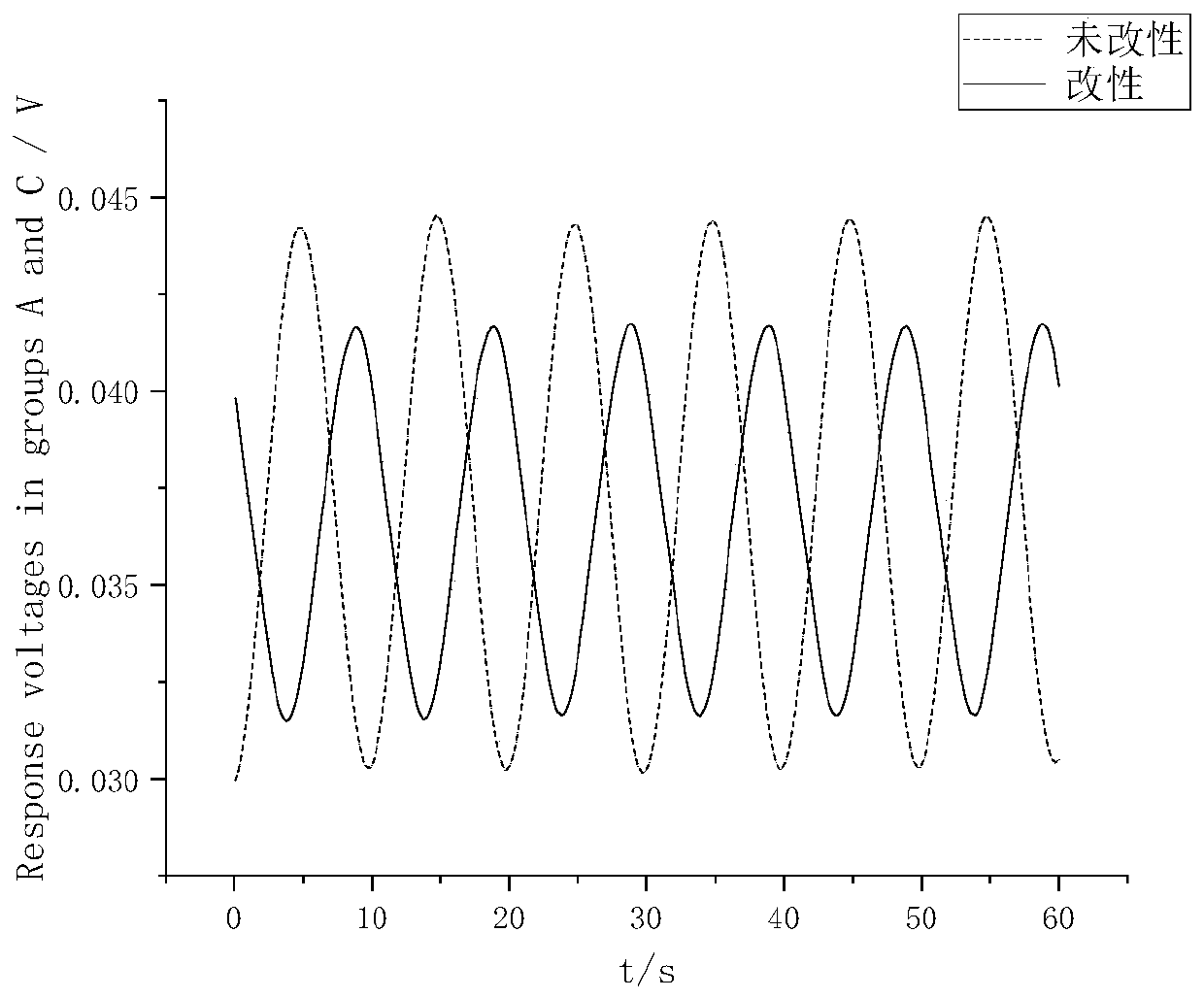

Carbon fiber electrode for detecting low-frequency marine electric field and preparation method thereof

ActiveCN110389384AThe electrode has a large specific surface areaImprove surface activityPhysical treatmentCarbon fibresCarbon fibersElectric field

The invention discloses a carbon fiber electrode for detecting a low-frequency marine electric field and a preparation method thereof. The method comprises the steps of: after a ultrasonic and concentrated nitric acid combined oxidation treatment on a common viscose-based carbon fiber, coating the carbon fiber with a nanocomposite film as an electrode core; preprocessing the carbon fiber with ethanol, then immersing the preprocessed carbon fiber in concentrated nitric acid, and oxidizing the preprocessed carbon fiber in an ultrasonic environment; immersing the oxidized carbon fiber in the prepared nanocomposite dispersion, pulling the oxidized carbon fiber by a pulling method, drying the product for 24 hours, and coating the surface of the carbon fiber with a transparent film; connecting the tail end of the carbon fiber with a copper column, coating the carbon fiber with a sealing ring, and placing the whole electrode in an electrode protective cover with a small hole to complete the package. The electrode prepared by the method has the advantages of large specific area and high surface activity so as to respond correctly to low-frequency electric field signals. The applied nano film has high mechanical strength and good thermal stability.

Owner:合肥名龙电子科技有限公司

Preparation method of thermoplastic polyurethane film

PendingCN112708259ALower glass transition temperatureImprove carrying capacityFlat articlesPolymer scienceAntioxidant

The invention relates to the technical field of protective films, in particular to a preparation method of a thermoplastic polyurethane film, which comprises the following raw materials: polyurethane, dimethylformamide, an antioxidant, an ultraviolet light absorber, an antibacterial agent, a lubricant and a filler. Polyurethane and dimethylformamide are adopted as main materials to improve polyurethane material molecules so as to achieve a strong stretching effect, a slit trial extrusion type coating high-temperature baking thermosetting mode is adopted in the preparation process, products with different hardness can be obtained by changing the proportion of all reaction components of polyurethane, along with the increase of the hardness, the product still maintains good elasticity and wear resistance, the bearing capacity, impact resistance and shock absorption performance of a polyurethane product are outstanding, the glass transition temperature of polyurethane is relatively low, and good elasticity, flexibility and other physical properties are still maintained at the temperature of -35 DEG C.

Owner:揭西鑫昌顺电子科技有限公司

A kind of reinforced polyethylene film and preparation method thereof

The invention relates to a reinforced polyethylene (PE) film and a preparation method thereof, belonging to the technical field of functional packaging materials. The preparation method comprises the following steps: by using modified nano kaolin as a toughener, modified organic montmorillonite as a reinforcer and organic montmorillonite and maleic anhydride grafted PE as compatibilizers, adding a certain lubricant; and by using the PE as the substrate, carrying out blow molding to form the film. The reinforced PE composite film has the advantages of high stability, high barrier property, certain flame retardancy, high stretchability, high elongation at break and favorable aging resistance, can be widely used in the fields of daily supplies, household appliances and the like, and widens the application range of the PE material.

Owner:JIANGNAN UNIV

Waterproof, wear-resistant, and flame-retardant super adhesive tape

InactiveCN108864976AImprove stabilityHigh mechanical strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesFiberWear resistant

The invention discloses a waterproof, wear-resistant and flame-retardant supper adhesive tape. The adhesive tape comprises an adhesive layer, a middle layer and an outer layer. The outer layer is a polyvinyl chloride waterproof layer; the middle layer is a flame-retardant fiber cloth layer, and the flame-retardant fiber cloth layer is heat sealed on the outer layer; and the adhesive layer is applied to the flame retardant fiber cloth layer. The tape provided by the invention has high stability and can be continuously adhered; the tape does not easily peel off, the wound tape is prevented fromedge warping so that the replacement frequency is effectively reduced; the tape has high mechanical strength, strong tensile strength, and enough thickness; the tape is anti-aging, waterproof, flame-retardant and wear-resistant; and the tape is easy to be applied to bundling or repairing wires, filling construction joints, and material bonding.

Owner:阜南县力韦包装材料有限公司

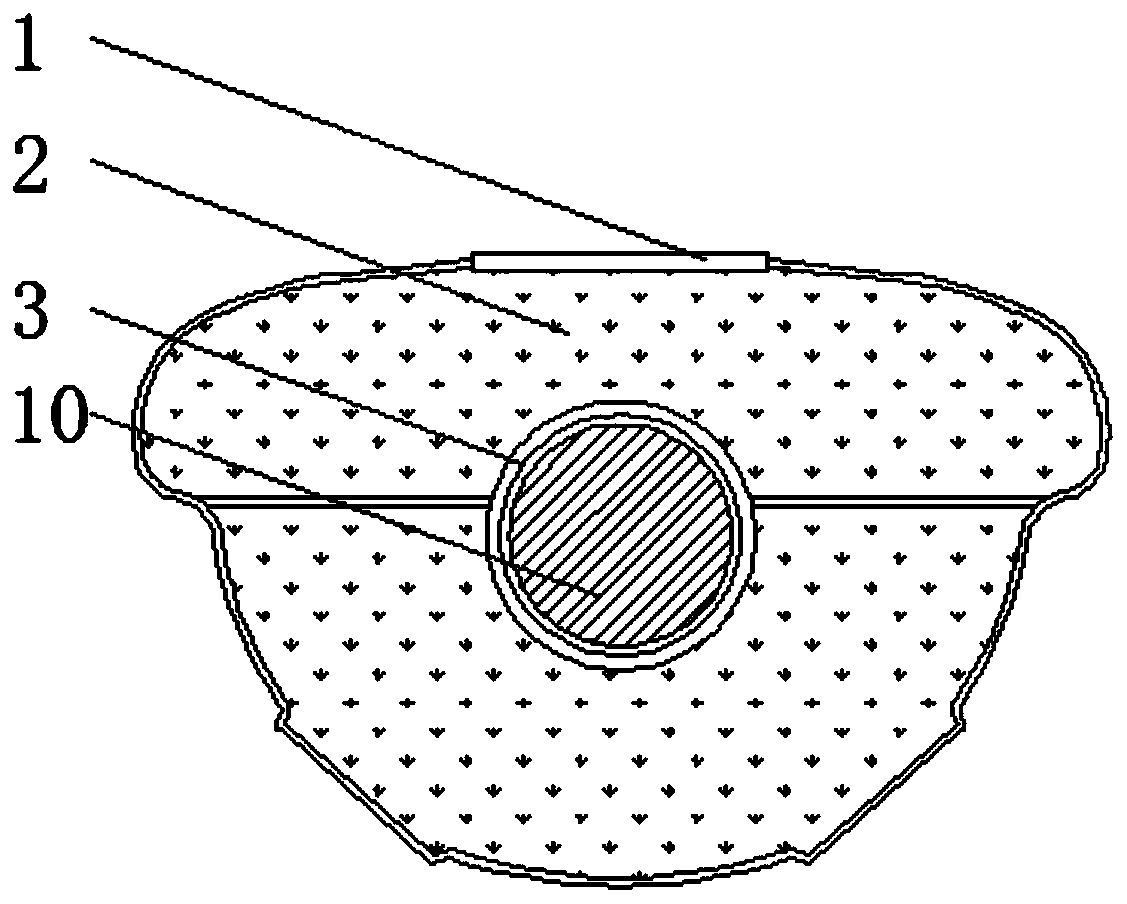

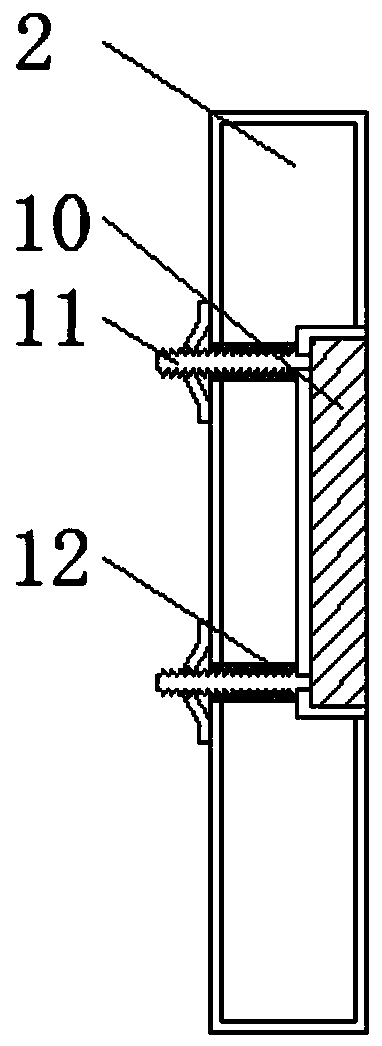

Composite material cover cap for automobile airbag

InactiveCN108639002AImprove tensile propertiesSolve the shock absorption functionPedestrian/occupant safety arrangementEngineeringMotor vehicle airbag

The invention discloses a composite material cover cap for an automobile airbag. The composite material cover cap comprises a cover body, a baffle plate, first studs, a logo body and a fiber layer. Apreformed groove is formed in one end of the cover body, and the logo body is mounted at the end, away from the cover body, of the preformed groove. Clamping blocks are uniformly disposed at the edgeof the end, close to the preformed groove, of the logo body, and clamping grooves matched with the clamping blocks are uniformly formed in the end, close to the logo body, of the cover body. Chucks are fixed to the cover body, away from one end of the logo body, of the clamping blocks, and clamping connecting pieces are disposed on the sides, close to the clamping blocks, of the chucks. Baffle blocks are separately mounted at the top and bottom of the other end of the cover body, and screw holes are evenly formed in the baffle blocks. According to the composite material cover cap for the automobile airbag, the clamping blocks are installed at the edge of one side of the logo body, and the clamping grooves matched with the clamping blocks are uniformly formed in the cover body, so that thelogo body is conveniently detached from the cover body, the installation is convenient, and the production cost of enterprises is reduced.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

A preparation method of antibacterial repair type medical non-woven fabric

InactiveCN107364195BHas antibacterial and deodorizing functionsAdhesiveLaminationLamination apparatusSterile waterNonwoven fabric

The invention discloses a preparation method of an antibacterial repairing type medical non-woven fabric. The preparation method is characterized by including: (1) opening: cleaning blend fibers in bacteria-free water for 2-3 times, and heating for opening; (2) combing to form a net: oscillating the blend fibers by ultrasonic waves with frequencies of 40 kHz and 25kHz, and settling to obtain a blend fiber net; (3) atomized water spraying: using pressurized atomized water to spray the front side and the reverse side of the blend fiber net; (4) drying: drying the blend fiber net in a low temperature after being sprayed by the atomized water; (5) preparing a bamboo fiber layer: preparing the dried blend fiber net into a bamboo fiber net layer according to the steps from (1) to (4); laminating by heat sealing: overlaying a tea fiber net layer with the bamboo fiber net layer, and adding medicament powder prior to laminating. The preparation method has the advantages that the prepared antibacterial repairing type medical non-woven fabric is uniform in thickness, high in stretchability, long in sterilizing effect lasting time and capable of healing a wound quickly and removing wound scars after being used.

Owner:JIESHOU SHUANGXIN TEXTILE

A kind of modified nano barium sulfate reinforced polypropylene membrane and preparation method thereof

The invention relates to a polypropylene film reinforced by modified nano barium sulfate and a preparation method of the polypropylene film and belongs to the technical field of functional packaging materials. The polypropylene film is prepared by using the modified nano barium sulfate as the toughening agent and organic montmorillonite and maleic anhydride grafted polyethylene as the compatibilizer, adding certain reinforcing agent and using PP as base material through blowing. The reinforced composite polypropylene film prepared by the method is good in heat resistance, high in barrier property, high in tensile property, high in breaking elongation rate and good in anti-aging performance, has certain flame retardance, and is widely applicable to fields such as daily necessities and household appliances.

Owner:WUXI JIATAI TECH

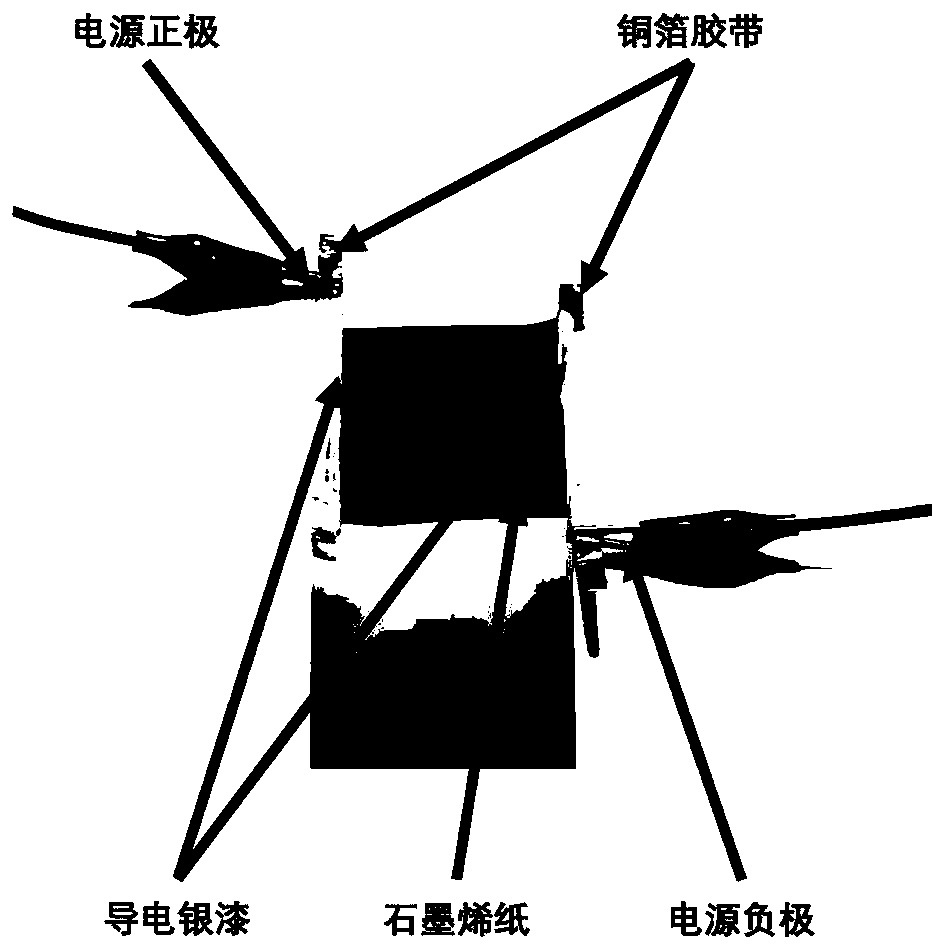

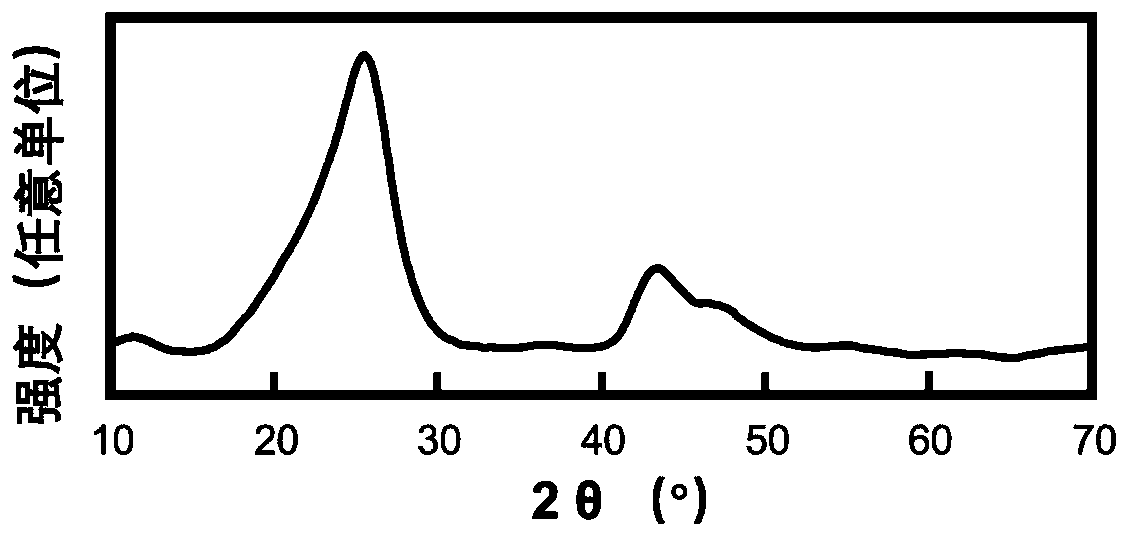

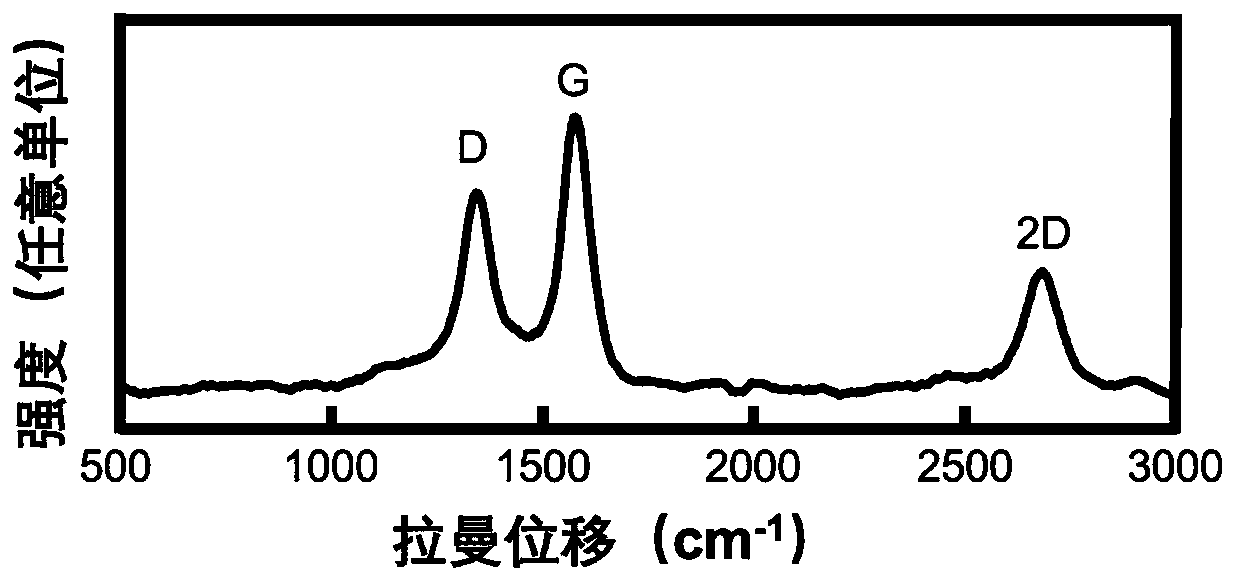

Adjustable laser-induced graphene paper heater and application thereof

ActiveCN111432507AWide heating temperature rangeImprove heating efficiencyHeating fuelLighting and heating apparatusEngineeringGraphite

The invention provides a laser-induced graphene paper heater and application thereof, and belongs to the technical field of heaters. The laser-induced graphene paper heater comprises a graphene paper,electrodes are pasted to the two ends of the graphene paper respectively, the joints of the electrodes and the graphene paper are coated with conductive silver paint, and the graphene paper is prepared by the laser-induced reduction of a polyimide paper. The graphene paper heater is larger in heating temperature range, high in heating efficiency and high in temperature rising speed. Furthermore,the patterned graphene paper is obtained by one-time processing through the laser digital customized design and manufacturing, so that the patterned graphene paper heater is convenient to further prepare; and the temperature region regulation and control can be realized by changing an equivalent circuit connection mode and a region area mode, so that the graphene paper heater can be applied to theaspects of wearable equipment, household heating, industrial heating equipment, thermosetting composite material low-energy-consumption curing molding and the like, and is wide in application prospect.

Owner:北京烯塔科技有限公司

Plastic thin film with high stretch resistance

InactiveCN109082003AStrong tensile propertiesAvoid tearingPolypropyleneEthylene glycol monomethyl ether

The invention discloses a plastic thin film with high stretch resistance. The plastic thin film comprises, by weight, 44-46 parts of polypropylene resin, 35-37 parts of epoxy resin, 52-54 parts of ethylene glycol monomethyl ether, 46-48 parts of ethylene glycol monoethyl ether, 6-8 parts of magnesium chloride, 11-13 parts of fly ash, 8-10 parts of light calcium carbonate, 5-7 parts of toughening agents, 3-5 parts of plasticizers and 2-4 parts of stabilizers. According to the technical scheme, the plastic thin film has the advantages that the plastic thin film is mainly made from the polypropylene resin and the epoxy resin, fill substances such as the magnesium chloride, the fly ash and the light calcium carbonate are added into the polypropylene resin and the epoxy resin, accordingly, theprepared plastic thin film is high in stretch resistance and can be widely popularized and used, and tearing can be prevented when the plastic thin film is used.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com