Corrosion-resistant film material and preparation method thereof

A film material and corrosion-resistant technology, applied in the field of corrosion-resistant film materials and their preparation, can solve the problems of low fatigue strength, high forming temperature, low thermal deformation temperature, etc., and achieve moderate deformation temperature, strong tensile ability, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

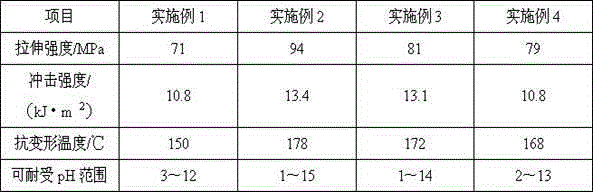

Examples

Embodiment 1

[0027] A corrosion-resistant film material. The packaging material is mainly composed of a carrier material, an adhesive resin, and a novolac epoxy resin for high-temperature adhesives; the carrier material is made according to the following ratio of raw materials by weight: ethylene-vinyl acetate copolymer 2 parts of high polymer polypropylene, 1 part of polysulfone, among which the quantitative requirement of ethylene-vinyl acetate copolymer is 20 g / m 2 , high polymer polypropylene 15 g / m 2 , Polysulfone 13 g / m 2 ; The binding resin is suitable for impregnating melamine formaldehyde resin or melamine urea formaldehyde resin, wherein the solid content of the resin is 41%.

[0028] A method for preparing a corrosion-resistant film material, comprising the following steps:

[0029] (1) Melt ethylene-vinyl acetate copolymer, high-polymer polypropylene and polysulfone at high temperature, and mix them uniformly. The melting temperature is 179°C;

[0030] (2) Pour the mixture o...

Embodiment 2

[0034] A corrosion-resistant film material. The packaging material is mainly composed of a carrier material, an adhesive resin, and a novolac epoxy resin for high-temperature adhesives; the carrier material is made according to the following ratio of raw materials by weight: ethylene-vinyl acetate copolymer 6 parts, 8 parts of high polymer polypropylene, 9 parts of polysulfone, of which the quantitative requirement of ethylene-vinyl acetate copolymer is 28 g / m 2 , high polymer polypropylene 21g / m 2 , Polysulfone 24 g / m 2 ; The binding resin is suitable for impregnating melamine formaldehyde resin or melamine urea formaldehyde resin, wherein the solid content of the resin is 48%.

[0035] A method for preparing a corrosion-resistant film material, comprising the following steps:

[0036] (1) Melt ethylene-vinyl acetate copolymer, high-polymer polypropylene and polysulfone at high temperature, and mix them uniformly. The melting temperature is 202°C;

[0037] (2) Pour the mix...

Embodiment 3

[0041] A corrosion-resistant film material. The packaging material is mainly composed of a carrier material, an adhesive resin, and a novolac epoxy resin for high-temperature adhesives; the carrier material is made according to the following ratio of raw materials by weight: ethylene-vinyl acetate copolymer 11 parts, high polymer polypropylene 12 parts, polysulfone 14 parts, of which ethylene-vinyl acetate copolymer quantitative requirements 30 g / m 2 , high polymer polypropylene 22 g / m 2 , Polysulfone 23 g / m 2 ; The binding resin is suitable for impregnating melamine formaldehyde resin or melamine urea formaldehyde resin, wherein the solid content of the resin is 48%.

[0042] A method for preparing a corrosion-resistant film material, comprising the following steps:

[0043] (1) Melt ethylene-vinyl acetate copolymer, high polymer polypropylene and polysulfone at high temperature, and mix them evenly, with a melting temperature of 204°C;

[0044] (2) Pour the mixture obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com