Toughened polyvinyl alcohol composite hydrogel and application thereof

A composite hydrogel and polyvinyl alcohol technology, applied in the toughened polyvinyl alcohol composite hydrogel, covering the field of protective hazardous chemicals, can solve the problem of delaying the volatilization and diffusion of hazardous chemicals, so as to delay the volatilization and diffusion, reduce the damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 12.90 g of polyvinyl alcohol and 2.50 g of sodium alginate were dissolved in 100 mL of aqueous solution to obtain component A with a polyvinyl alcohol concentration of 129.0 mg / mL and a sodium alginate concentration of 25.0 mg / mL;

[0023] 2.58 g of borax was dissolved in 100 mL of aqueous solution to obtain component B with a borax concentration of 25.8 mg / mL.

[0024] Under electromagnetic stirring, component B (1 mL) was quickly added to component A (1 mL), and a hydrogel was formed after about 100 seconds.

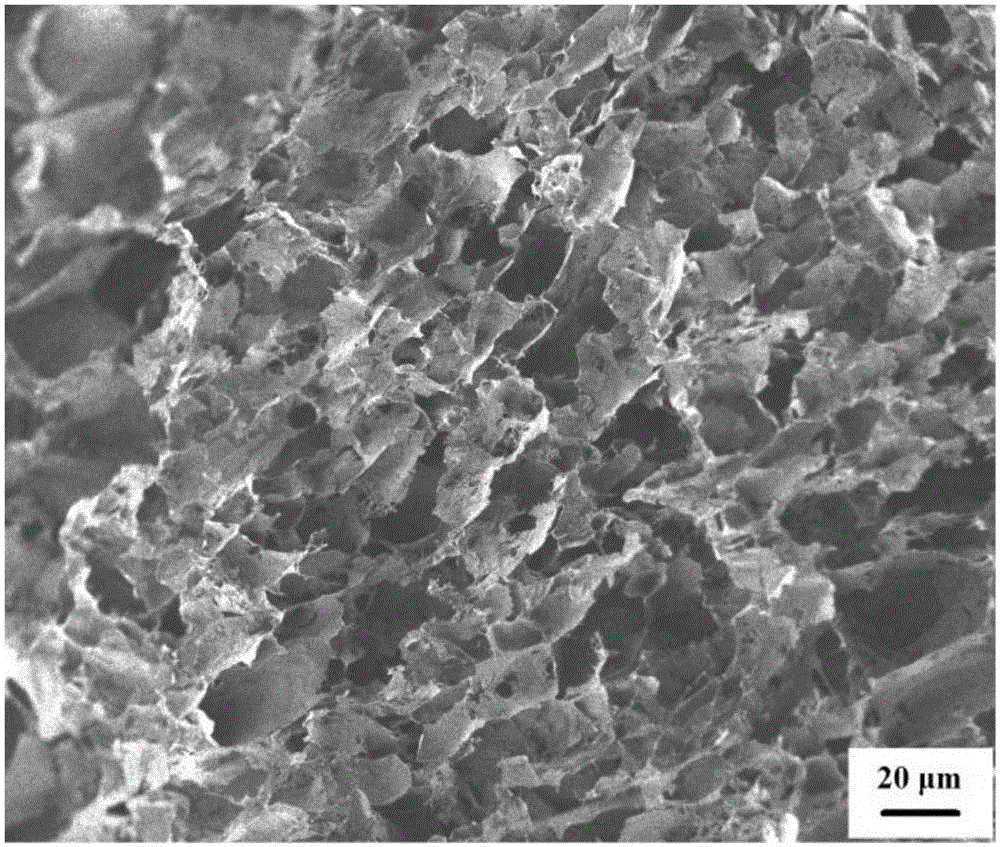

[0025] figure 1 It is a scanning electron microscope picture of the above-mentioned hydrogel, which is a semi-interpenetrating three-dimensional network structure, sodium alginate uniformly runs through the entire network structure, and the pore size is about 20 μm.

Embodiment 2

[0027] 35.50 g of polyvinyl alcohol and 1.50 g of sodium alginate were dissolved in 100 mL of aqueous solution to obtain component A with a concentration of polyvinyl alcohol of 355.0 mg / mL and a concentration of sodium alginate of 15.0 mg / mL;

[0028] 1.42 g of borax was dissolved in 100 mL of aqueous solution to obtain component B with a borax concentration of 14.2 mg / mL.

[0029] Under electromagnetic stirring, component B (1 mL) was quickly added to component A (1 mL), and a hydrogel was formed after about 59 seconds.

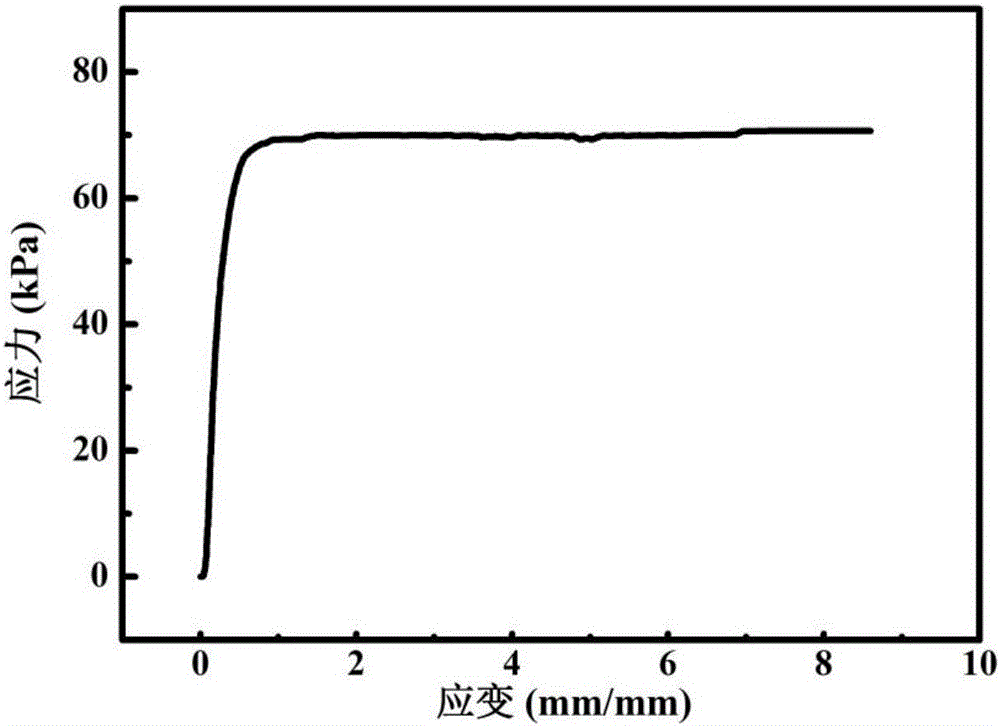

[0030] figure 2 It is the tensile property graph of the above-mentioned hydrogel, and the maximum tensile strength is 69.25kPa. The addition of sodium alginate makes the hydrogel form a semi-interpenetrating network structure, and the force between the molecular chains is enhanced, so that the tensile strength of the gel increases during the deformation process and is not easy to break.

Embodiment 3

[0032] 20.20 g of polyvinyl alcohol and 0.40 g of sodium alginate were dissolved in 100 mL of aqueous solution to obtain component A with a polyvinyl alcohol concentration of 202.0 mg / mL and a sodium alginate concentration of 4.0 mg / mL;

[0033] 5.60 g of borax was dissolved in 100 mL of aqueous solution to obtain component B with a borax concentration of 56.0 mg / mL.

[0034] The gelation time was determined to be 99 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com