Production technology of gold and palladium-plated bonding copper wire for encapsulation

A production process and technology of copper wire, which is applied in the field of production process of gold-plated palladium-bonded copper wire for semiconductor integrated circuit packaging, can solve the problem of unstable electroplating layer of gold-plated palladium-bonded copper wire, easy oxidation of key surface, poor high temperature stability, etc. problem, to achieve the effect of consistent deformation, uniform surface, strong ductility and tensile resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The method for manufacturing the gold-plated palladium bonding copper wire proposed by the present invention will be described in detail below through specific implementation methods.

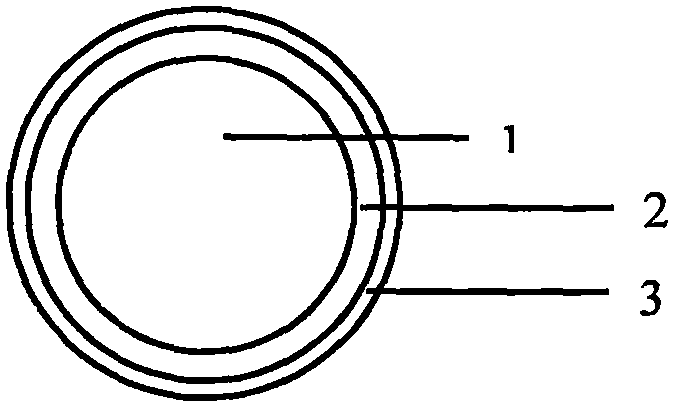

[0013] The gold-plated palladium bonding copper wire proposed in the embodiment of the present invention has a specific structure such as figure 1 As shown, it includes a central copper wire 1, an electroplated palladium layer 2, and an electroplated gold layer 3. Among them, the raw material of the central copper wire 1 is single crystal copper with a purity greater than 99.999%, which is then cast in a high-temperature environment by adding silver, silicon, calcium, aluminum, iron and nickel trace elements; Metal palladium is plated on the surface of the central copper wire by an electroplating process, and the palladium layer can alleviate the problem of oxidation of the central copper wire and the problem of silver drift in the central copper wire, and the binding force between palla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com