Carbon fiber electrode for detecting low-frequency marine electric field and preparation method thereof

A carbon fiber electrode and carbon fiber technology, which is applied in the direction of carbon fiber, fiber treatment, electromagnetic field characteristics, etc., can solve the problems of low surface activity and inability to respond to weak low-frequency signals, etc., achieve high surface activity, promote oxidation and etching, and increase ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

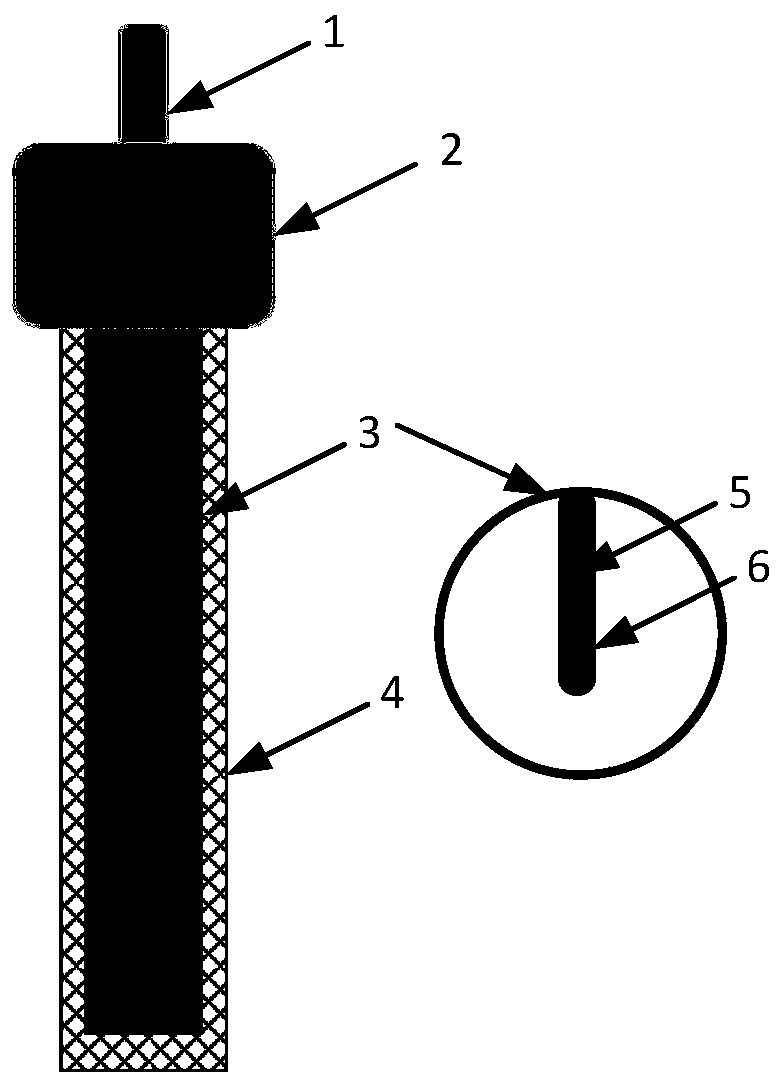

[0028] Such as figure 1 As shown, a new type of carbon fiber electrode for low-frequency ocean electric field detection, its structure includes a copper column 1 for circuit connection, a waterproof sealing ring 2, an electrode body 3, and an electrode protective cover 4. The surface structure of a single carbon fiber includes an oxidized Viscose-based carbon fiber5, nanocomposite film6.

[0029] The electrode preparation method is as follows:

[0030] 1) Pretreatment: place the carbon fiber in an anhydrous ethanol solution and ultrasonically clean it for 90 minutes, wash it with distilled water, and put it in an oven at 80°C for 2 hours;

[0031] 2) Ultrasonic + Concentrated Nitric Acid Combined Oxidation Treatment: Soak the treated carbon fiber in 1) in concentrated nitric acid, treat it in an ultrasonic instrument at 110°C for 4 hours, then wash it with deionized water and absolute ethanol until pH>6, and dry it Stand still for 1 day under constant temperature and humidit...

Embodiment 2

[0036] Such as figure 1 As shown, a new type of carbon fiber electrode for low-frequency ocean electric field detection, its structure includes a copper column 1 for circuit connection, a waterproof sealing ring 2, an electrode body 3, and an electrode protective cover 4. The surface structure of a single carbon fiber includes an oxidized Viscose-based carbon fiber5, nanocomposite film6.

[0037] The electrode preparation method is as follows:

[0038] 1) Pretreatment: place the carbon fiber in an anhydrous ethanol solution and ultrasonically clean it for 90 minutes, wash it with distilled water, and put it in an oven at 80°C for 2 hours;

[0039] 2) Ultrasonic + Concentrated Nitric Acid Combined Oxidation Treatment: Take 1) the treated carbon fiber and soak it in concentrated nitric acid, treat it in an ultrasonic instrument at 70°C for 4 hours, then wash it with deionized water and absolute ethanol until ph>6, and dry it Stand still for 1 day under constant temperature and...

Embodiment 3

[0044] Such as figure 1 As shown, a new type of carbon fiber electrode for low-frequency ocean electric field detection, its structure includes a copper column 1 for circuit connection, a waterproof sealing ring 2, an electrode body 3, and an electrode protective cover 4. The surface structure of a single carbon fiber includes an oxidized Viscose-based carbon fiber5, nanocomposite film6.

[0045] The electrode preparation method is as follows:

[0046] 1) Pretreatment: place the carbon fiber in an anhydrous ethanol solution and ultrasonically clean it for 90 minutes, wash it with distilled water, and put it in an oven at 80°C for 2 hours;

[0047] 2) Ultrasonic + Concentrated Nitric Acid Combined Oxidation Treatment: Take 1) treated carbon fiber and soak it in concentrated nitric acid, treat it in an ultrasonic instrument at 150°C for 4 hours, then wash it with deionized water and absolute ethanol until pH>6, and dry it Stand still for 1 day under constant temperature and hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com