A preparation method and application of titanium grid-supported tin electrode based on high-pressure spraying method

A spraying method and titanium mesh technology, applied in the field of electrochemistry, can solve the problems of easily destroying electrode surface catalysts, poor electrode corrosion resistance, surface catalyst peeling, etc., and achieve the problem of inhibiting coating peeling, stable electrocatalytic activity, and increasing stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

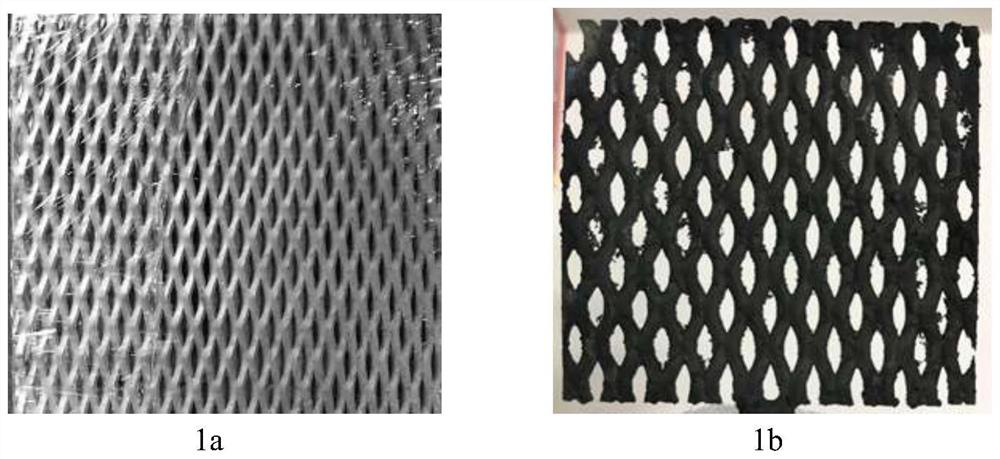

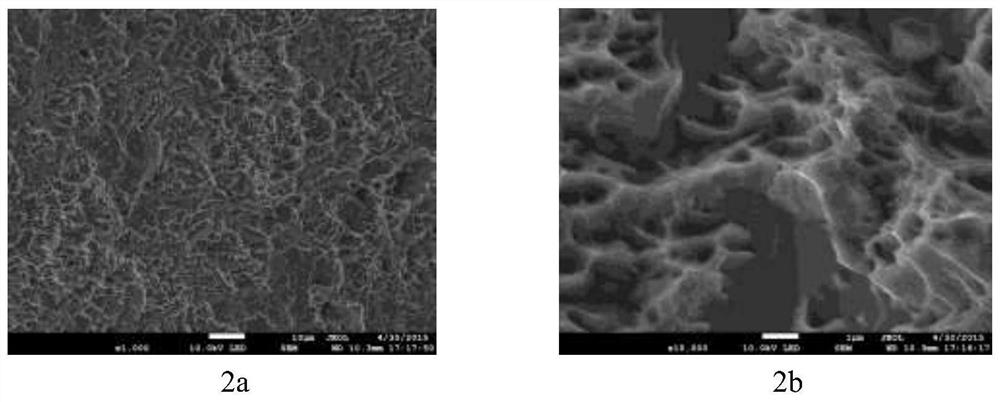

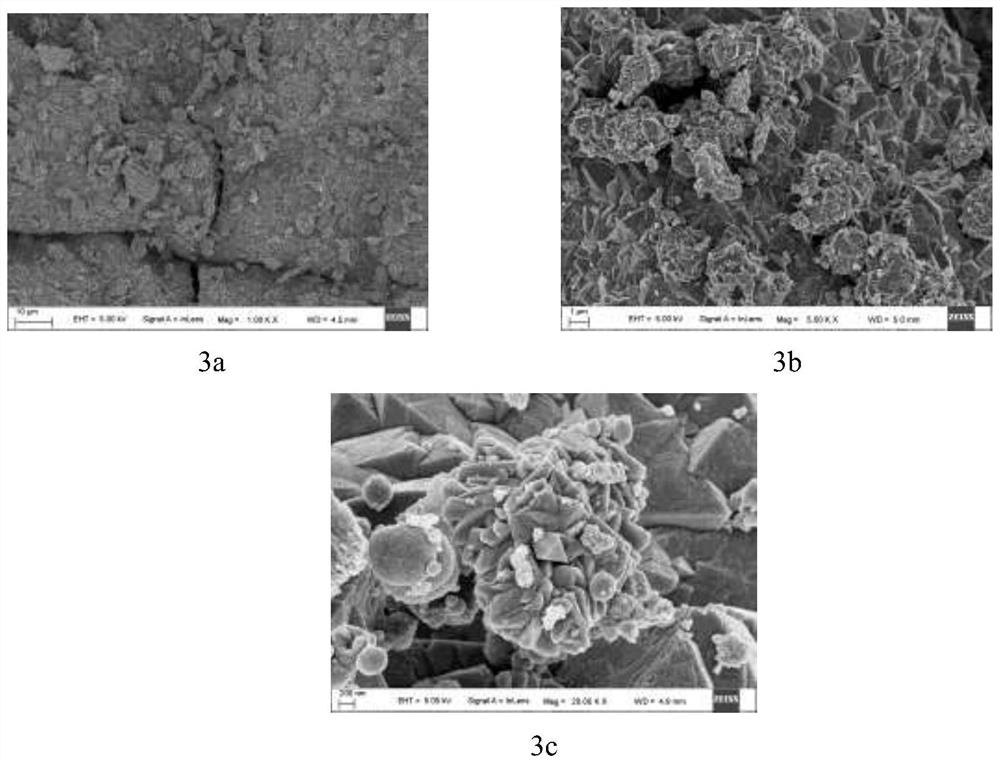

[0035] Embodiment 1, a kind of preparation method of the titanium grid-supported tin electrode based on high-pressure spraying method, carries out according to the following steps:

[0036] S1: Put the titanium mesh substrate in 0.1-0.5mol / L sodium hydroxide solution and boil until slightly boiled to remove the oil stain on the surface of the titanium mesh substrate, and then place the oil-removed titanium mesh in a saturated oxalic acid solution for etching 2h until the surface forms pockmarks;

[0037] S2: Weigh SbCl 3 Place in a dry beaker, add an appropriate amount of concentrated hydrochloric acid to the beaker to SbCl 3 Just completely dissolved, continue to add diethanolamine and a certain amount of SnCl to the beaker 4 4H 2 O mixed, cooled and fully stirred until the solution became white and viscous, and stopped stirring, calculated by mass ratio, wherein SbCl 3 : concentrated hydrochloric acid: diethanolamine: SnCl 4 4H 2 O=6:20:320:600;

[0038] S3: Measure a...

Embodiment 2

[0043] Embodiment 2, a kind of preparation method of the titanium grid-supported tin electrode based on high-pressure spraying method, carry out according to the following steps:

[0044] S1: Put the titanium mesh substrate in 0.1-0.5mol / L sodium hydroxide solution and boil until slightly boiled to remove the oil stain on the surface of the titanium mesh substrate, and then place the oil-removed titanium mesh in a saturated hydrofluoric acid solution for engraving Etch for 2 hours until pitting is formed on the surface;

[0045] S2: weigh Sb separately 3 o 5 Place in a dry beaker, add an appropriate amount of concentrated sulfuric acid to the beaker to Sb 3 o 5 Just completely dissolved, continue to add triethanolamine and a certain amount of SnCl to the beaker 4 ·5H 2 O mixed, cooled and fully stirred until the solution became white and viscous, and stopped stirring, calculated by mass ratio, wherein Sb 3 o 5 :Concentrated sulfuric acid:Triethanolamine:SnCl 4 ·5H 2 O...

Embodiment 3

[0051] Embodiment 3, a kind of preparation method of the titanium grid-supported tin electrode based on high-pressure spraying method, carry out according to the following steps:

[0052] S1: Put the titanium mesh substrate in 0.1-0.5mol / L sodium hydroxide solution and boil until slightly boiled to remove the oil stain on the surface of the titanium mesh substrate, and then place the degreased titanium mesh in a saturated oxalic acid solution for 2 hours until the surface is pitted;

[0053] S2: weigh Sb separately 2 o 3 Place in a dry beaker, add an appropriate amount of concentrated nitric acid to the beaker to Sb 2 o 3 Just completely dissolved, continue to add ethylenediamine and a certain amount of SnCl to the beaker 2 2H 2 O mixed, cooled and fully stirred until the solution became white and viscous, and stopped stirring, calculated by mass ratio, wherein Sb 2 o 3 :Concentrated nitric acid:Diethylamine:SnCl 2 2H 2 O=6:22:270:550;

[0054] S3: Measure a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com