Method for processing anti-rust film

A processing method and anti-rust agent technology, applied in applications, household appliances, flat products, etc., can solve the problems of incomplete synthesis of anti-rust materials, burns, itching, redness and swelling of eyes and respiratory tract, etc., and achieve high impact resistance , enhanced physical properties, clean and dry workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

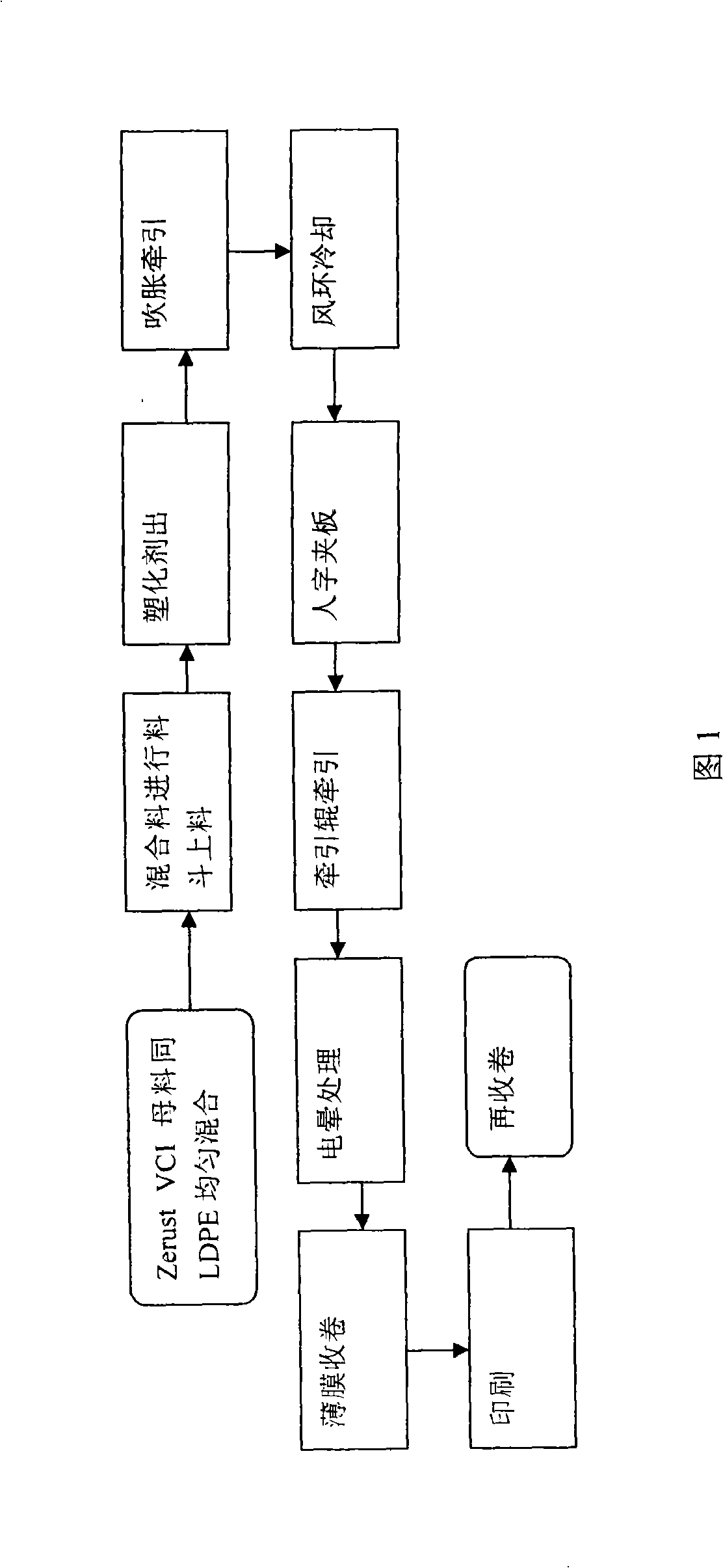

Method used

Image

Examples

Embodiment Construction

[0030] Zerust VCI Antirust Raw Material Ratio and Selection of Polyethylene Raw Material

[0031] Zerust VCI (Volatile Corrosion Inhibator) is a master batch composed of a variety of common rust inhibitors, oxygen scavengers and volatile agents. According to the different needs of metal protection and the production thickness and strength requirements of the antirust film, the formula ratio is 3-5%.

[0032] Among them, the composition of the masterbatch itself composed of a variety of common antirust agents, oxygen scavengers and volatile agents can be composed in various proportions according to the different needs of metal protection and the production thickness and strength requirements of the antirust film. (by weight)

[0033] The other raw material (95-97%) consists of polyethylene resin (LDPE). Other polyethylene resins (LDPE) must be selected according to the requirements of Zerust Company: polyethylene resin (LDPE) adopts new raw materials (no other additives); the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com