Albumin adhesive and preparation method thereof

An adhesive and albumin technology, applied in the field of albumin adhesive and its preparation, can solve the problems of poor mechanical properties, long production cycle, and the risk of virus transmission, and achieve the effects of strong mechanical tensile properties and enhanced bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

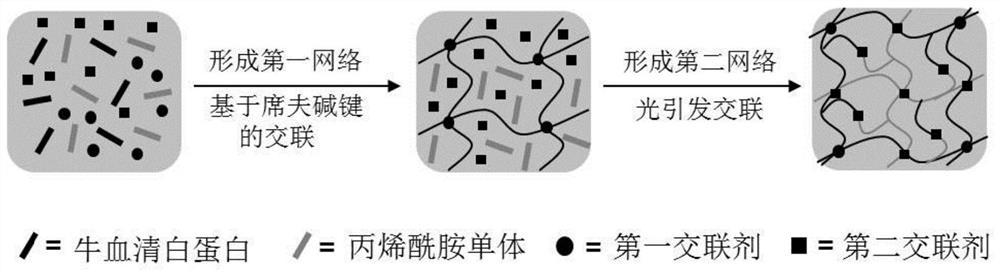

[0034] Embodiment 1: a kind of albumin adhesive and preparation method thereof:

[0035] (1) Take by weighing 5.0g bovine serum albumin (BSA) and dissolve in 10mL aqueous solution, be mixed with the BSA aqueous solution that mass concentration is 50%, add 3.0g acrylamide monomer (AAM) (mass concentration is 30%), then Add 0.0019g of methylene bisacrylamide (BIS) (molar concentration is 0.03mol%) and 0.095g of 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone (I2959) ( The molar concentration is 1 mol%), and the mixed solution was stirred at room temperature for 30 min to form a homogeneous solution.

[0036] (2) Add 300 μL of glutaraldehyde solution with a mass concentration of 10% to the homogeneous solution under stirring at room temperature, and form a pregel after stirring for 2 minutes;

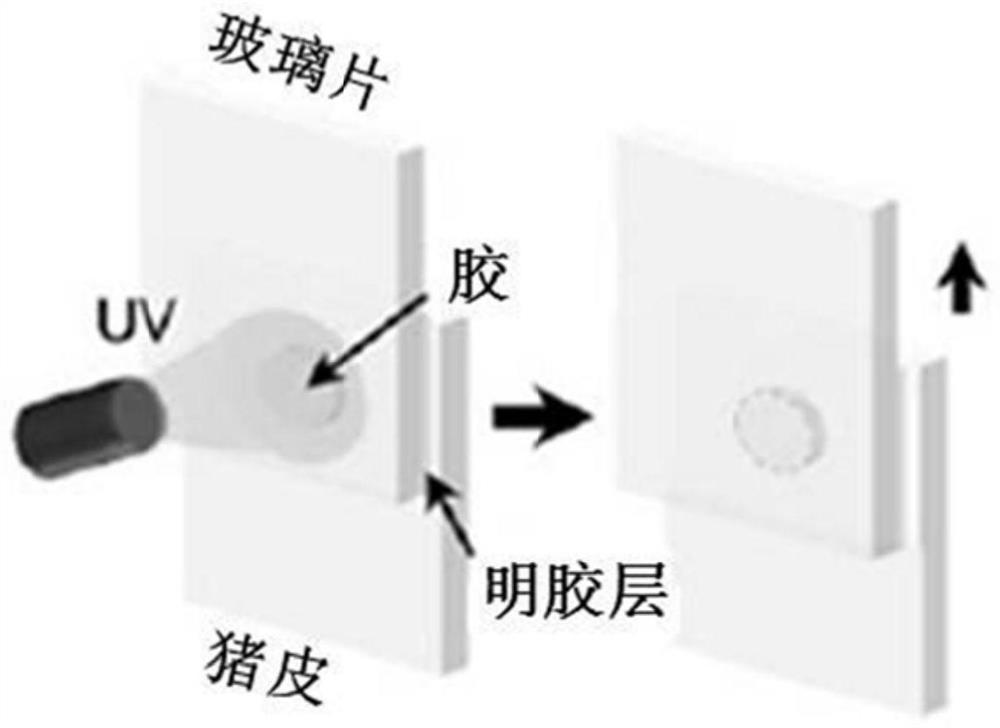

[0037] (3) The pre-glue is placed in ultraviolet light and irradiated with 365nm ultraviolet light for 3 minutes to obtain an albumin adhesive.

Embodiment 2

[0038] Embodiment 2: a kind of albumin adhesive and preparation method thereof:

[0039] (1) Take by weighing 2.0g bovine serum albumin (BSA) and dissolve in 10mL aqueous solution, be mixed with the BSA aqueous solution that mass concentration is 20%, add 3.0g acrylamide monomer (AAM) (mass concentration is 30%), again Added 0.0019g of methylenebisacrylamide (BIS) (molar concentration is 0.03mol%) and 19.4g of KIO 4 (the molar concentration is 1 mol%), the mixed solution was stirred at room temperature for 30 min to form a homogeneous solution.

[0040] (2) Add 300 μL of glutaraldehyde solution with a mass concentration of 10% to the homogeneous solution under stirring at room temperature, and form a pregel after stirring for 2 minutes;

[0041] (3) The pre-glue is placed in ultraviolet light and irradiated with 380nm ultraviolet light for 3 minutes to obtain an albumin adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com