Calcium carbide sensible heat recovery device

A technology of sensible heat recovery and calcium carbide, which is applied to heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of unusable heat energy, consumption of manpower and materials, and high labor intensity, so as to achieve the goal of avoiding crushing process, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

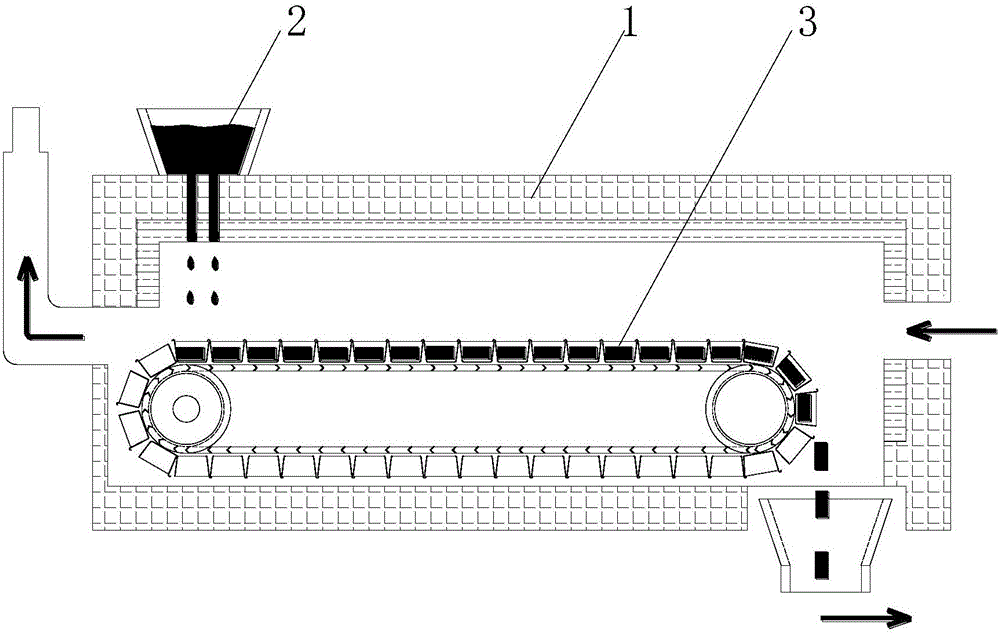

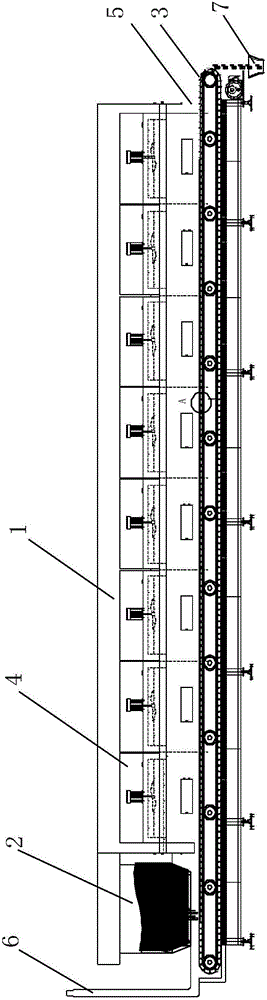

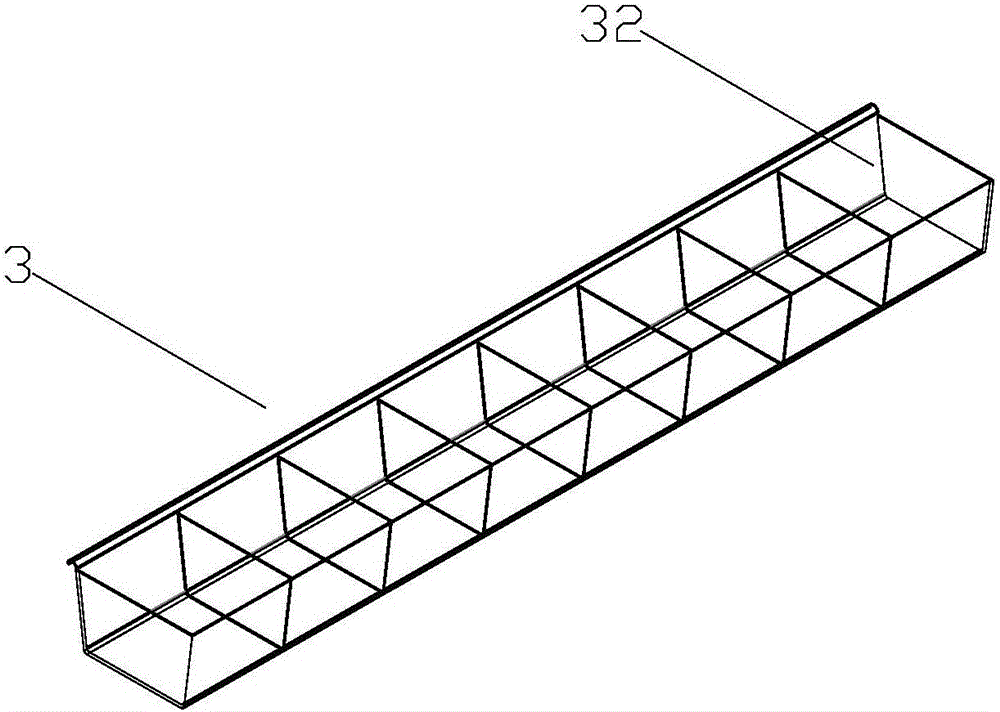

[0030] see figure 1 as well as figure 2 , is a schematic diagram of the calcium carbide sensible heat recovery device in the present invention. Such as figure 1 , figure 2 As shown, the calcium carbide sensible heat recovery device includes a heat exchange furnace 1, a recyclable forming mold 3 is arranged in the chamber of the heat exchange furnace 1, the forming mold 3 has a feeding end and a discharging end, and the feeding end of the forming mold 3 A plurality of air cooling devices 4 are arranged on the upper part between the outlet end and the molten calcium carbide in the forming mold to cool the calcium carbide into solid calcium carbide; the side wall of the heat exchange furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com