Energy-saving needle-shaped tea stir-frying machine and method for processing needle-shaped tea by using energy-saving needle-shaped tea stir-frying machine

A needle-bud-shaped tea and stir-frying technology, which is applied in the field of energy-saving needle-bud-shaped tea frying machines, can solve the problems of no needle-shaped tea, raw green taste and dark color, etc., and achieve the effect of tight, straight and beautiful strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

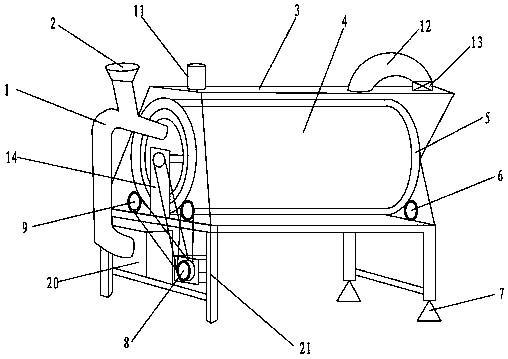

[0040] As shown in the figure, an energy-saving needle-bud tea frying machine includes a frame 21 , a shell 3 and a drum 4 . The shell 3 is fixedly arranged on the frame 21, and the drum 4 is arranged in rotation in the shell 3. The feeding end and the discharging end of the drum 4 are opened outside the shell 3, and a closed space is formed between the outer wall of the drum 4 and the shell 3.

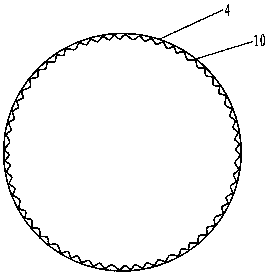

[0041] The drum 4 is a cylinder body. The inner wall of the drum 4 is a corrugated structure 10 . Specifically, the wavy structure 10 may be formed by a series of wavy curves arranged on the inner wall of the drum 4 along the length direction of the drum 4 .

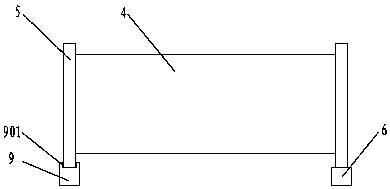

[0042]The feeding end and the discharging end of the drum 4 are provided with tires 5, the tires 5 at the feeding end of the drum 4 cooperate with the active positioning wheel support 9 arranged on the frame 21, the tires 5 at the discharging end of the drum 4 cooperate with the The driven wheel holder 6 on the frame 21 cooper...

Embodiment 2

[0047] The method for processing needle-bud-shaped green tea by using an energy-saving needle-bud-shaped tea frying machine comprises the following process steps:

[0048] 1) Spread the fresh leaves thinly to 1-2cm, and spread them at 24-30°C until the moisture content is 70%±1;

[0049] 2) Use a drum-type de-greening machine, a hot-air de-greening machine or a microwave de-greening machine to de-green the fresh tea leaves to a moisture content of 55-60%;

[0050] 3) Turn on the electric hot air stove 2, adjust the temperature of the hot air to 100-110°C, and blow it into the energy-saving needle bud-shaped tea frying machine;

[0051] 4) After the green leaves are cooled and softened, put the green leaves continuously into the energy-saving needle-bud tea frying machine from the green leaf input port 2, and pass the first fryer mounting seat according to the dryness and frying effect of the tea leaves after frying. 14 and the second stirrer mounting seat 15 adjust the height...

Embodiment 3

[0058] The method for processing needle-bud-shaped black tea using an energy-saving needle-bud-shaped tea frying machine comprises the following process steps:

[0059] 1) Thinly spread the fresh tea leaves to 1-2cm, and wither at 25-35°C until the moisture content is 60%±1;

[0060] 2) Put the withered leaves in step 1) into the rolling machine and knead for 90-120 minutes. The pressure process: air pressure for 5 minutes, light pressure, 15 minutes, medium pressure for 60-90 minutes, heavy pressure for 5 minutes, air pressure for 5 minutes;

[0061] 3) Ferment the rolled leaves of step 2) at 26-28°C and relative humidity of 92-97% for 3.5h-4h;

[0062] 4) Dry the fermented leaves in step 3) with a hot air dryer at 110-120°C to a moisture content of 35-40%;

[0063] 5) Cool the tea leaves obtained in 4) to below 35°C, then put them in a closed container and let them stand for 60-90 minutes;

[0064] 6) Turn on the electric hot air stove 2, adjust the hot air temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com