Continuous production line based on processing of black tea, green tea, yellow tea and white tea, and method thereof

A processing method and production line technology, which is applied in the field of multi-functional continuous production line equipment and tea processing, can solve the problems of a single tea variety and cannot meet the needs of tea farmers for processing multiple varieties of tea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

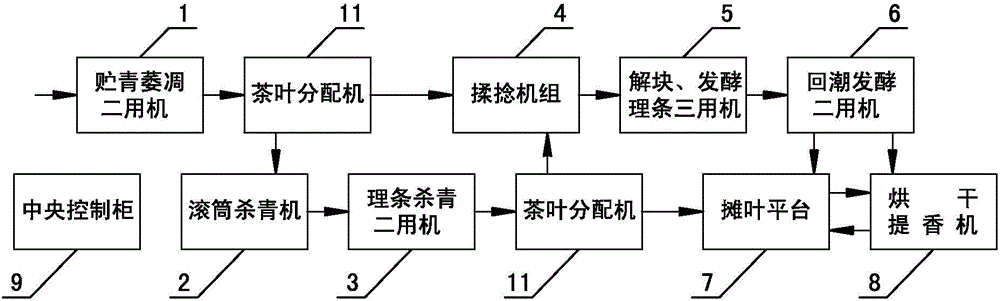

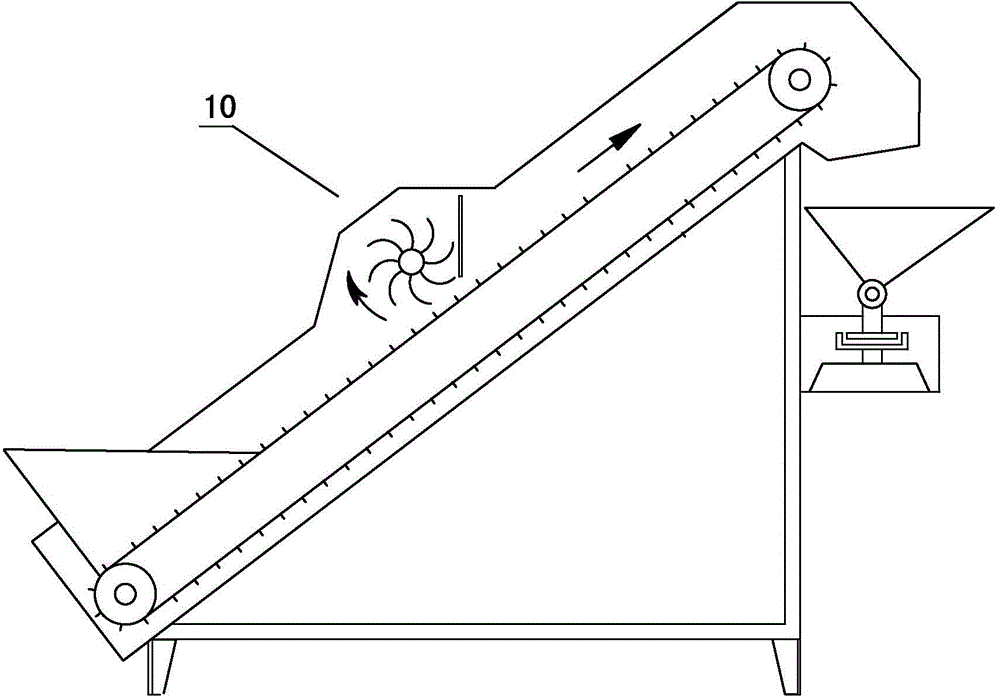

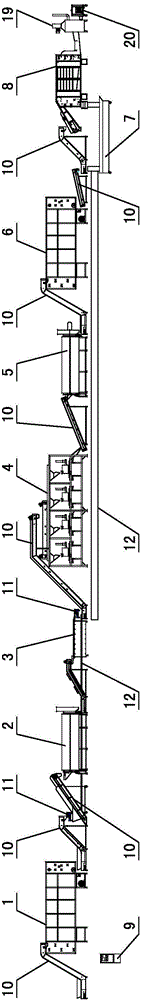

[0086] figure 1 It is a connection relationship block diagram of a kind of roasting equipment based on the continuous production line for processing black tea, green tea, yellow tea and white tea in the present invention, wherein the arrows in the figure indicate the flow direction of tea leaves. This embodiment includes tea roasting equipment and connected tea leaves The tea delivery equipment between the frying equipment, all the tea frying equipment and the tea delivery equipment are connected to the central control cabinet 9, the tea hoist 10 is connected to the green storage and withering dual-purpose machine 1, and the tea leaves of the green storage and withering dual-purpose machine Export and tea distribution machine 11, tea hoist and drum fixing machine 2 respectively (see Figure 7 ) and tea rolling unit 4 are connected, the tea outlet of the drum fixing machine is connected with the tea hoist and the two-purpose machine 3 for stripping and stripping, and the tea ou...

Embodiment 2

[0092]The drum fixing machine of embodiment 2 is two, and the tea outlet of green storage and withering dual-purpose machine is connected with two drum fixing machines by tea distribution machine, and the output of two drum fixing machines is combined and then connected to the two-purpose machine of stripping and fixing. The two-purpose machine for silage and withering of the present embodiment is placed in an incubator 17 (see Figure 6 ), the incubator is provided with a temperature regulator 18 in the box, the temperature control range of the incubator is 5 to 40 degrees, and the incubator is provided with a tea inlet and outlet. The lighting device is set close to the upper tea conveyor belt. Each lighting device includes several halogen lamps. The color temperature of the halogen lamp is 3000 to 4000 Kelvin, and the color temperature decreases linearly from top to bottom layer by layer. The distance between the halogen lamp and the upper tea conveyor belt is A reflective ...

Embodiment 3

[0094] The pellet fuel burner of embodiment 3 (see Figure 9 ) includes a housing (not shown in the figure), a feeding system, a burner and a main fan 22, the feeding system includes a hopper 23 and an equalizing auger 24 connected to the outlet of the hopper, and the output end of the equalizing auger The vertically arranged blanking channel 25 is connected to the pusher auger 26 arranged below the equalizing auger, and the output end of the pusher auger is connected to the burner 27, and the burner is arranged on the outside of the housing, including a A double-layer structure cylinder arranged horizontally, the inner cylinder 28 and the outer cylinder 29 of the cylinder are coaxially arranged, the rear end of the inner cylinder is provided with a rear end plate 30, and the upper part of the rear end plate is provided with a feeding hole 31, pushing The output end of the material auger is connected with the feed hole, the lower part of the rear end plate is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com